Sora Machine

Sora Machine was founded in 1981 by Mr. Yılmaz Kesme, the father of Barış Kesme, CEO of Sora Group. Sora Machine is the first manufacturer of aerosol product machines in Turkey, and has continued to offer innovative solutions to its customers using the most recent technology.

With over 40 years of experience in designing and manufacturing machinery, we have established a reputation for our expertise. Our team is able to promptly develop new projects for future products and offer high-quality services in various sectors. We are dedicated to providing flexible, timely responses to our customer’s needs. Quality is at the forefront of everything we do at Sora Machine, and it plays a crucial role in all of our business processes. Our goal is to systematically produce faster units while maintaining the highest level of quality. In the 21st century, our focus is on maximizing production without compromising on quality.

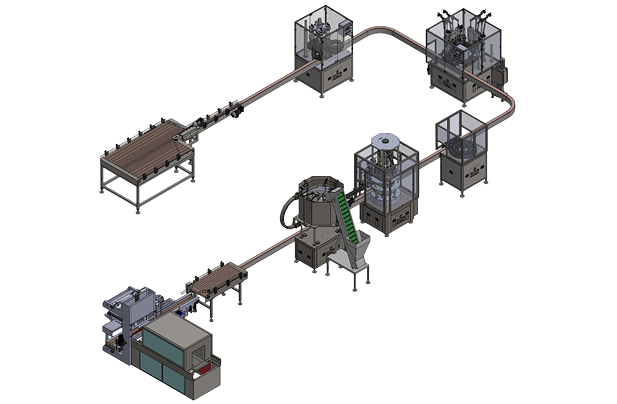

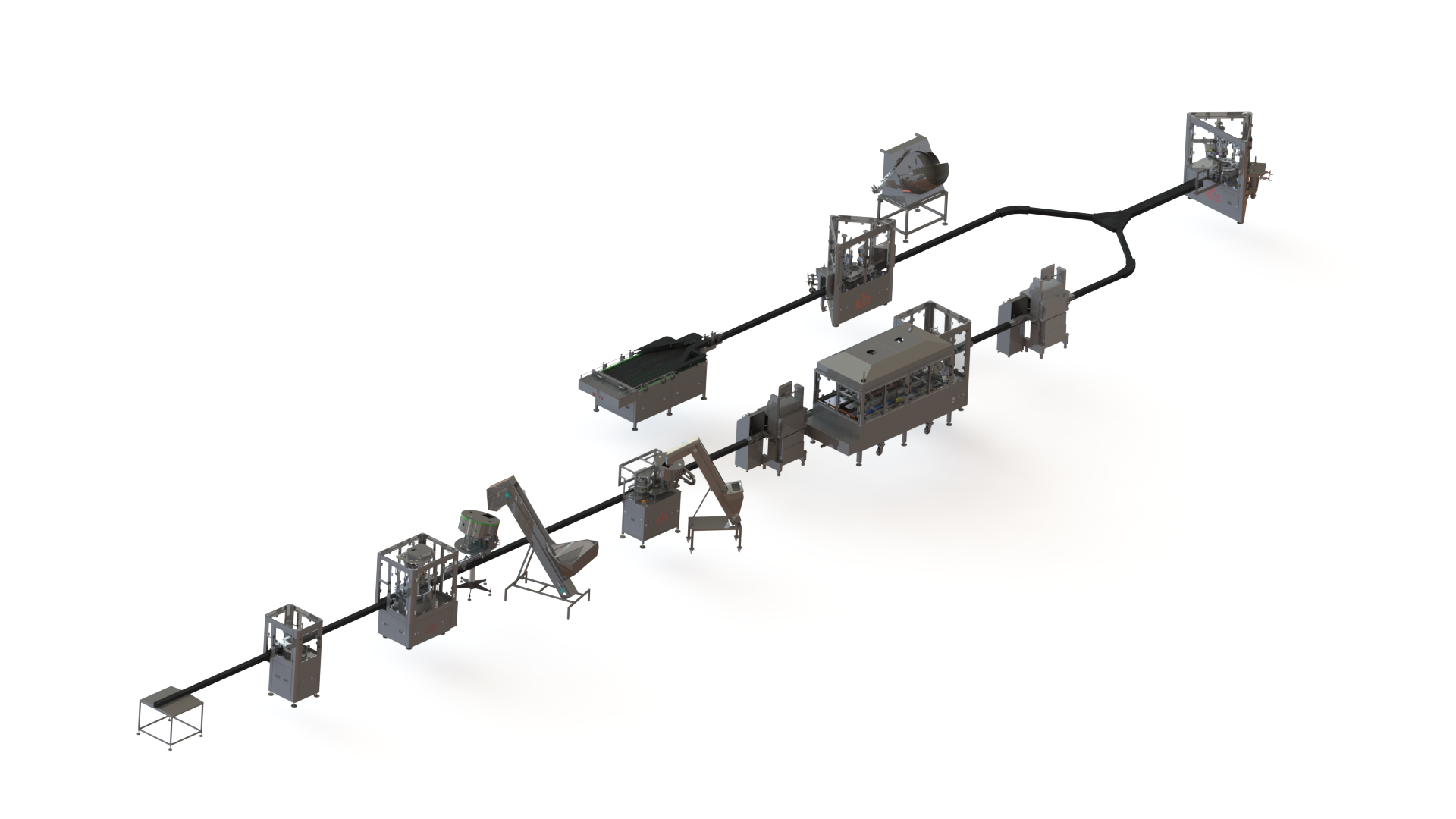

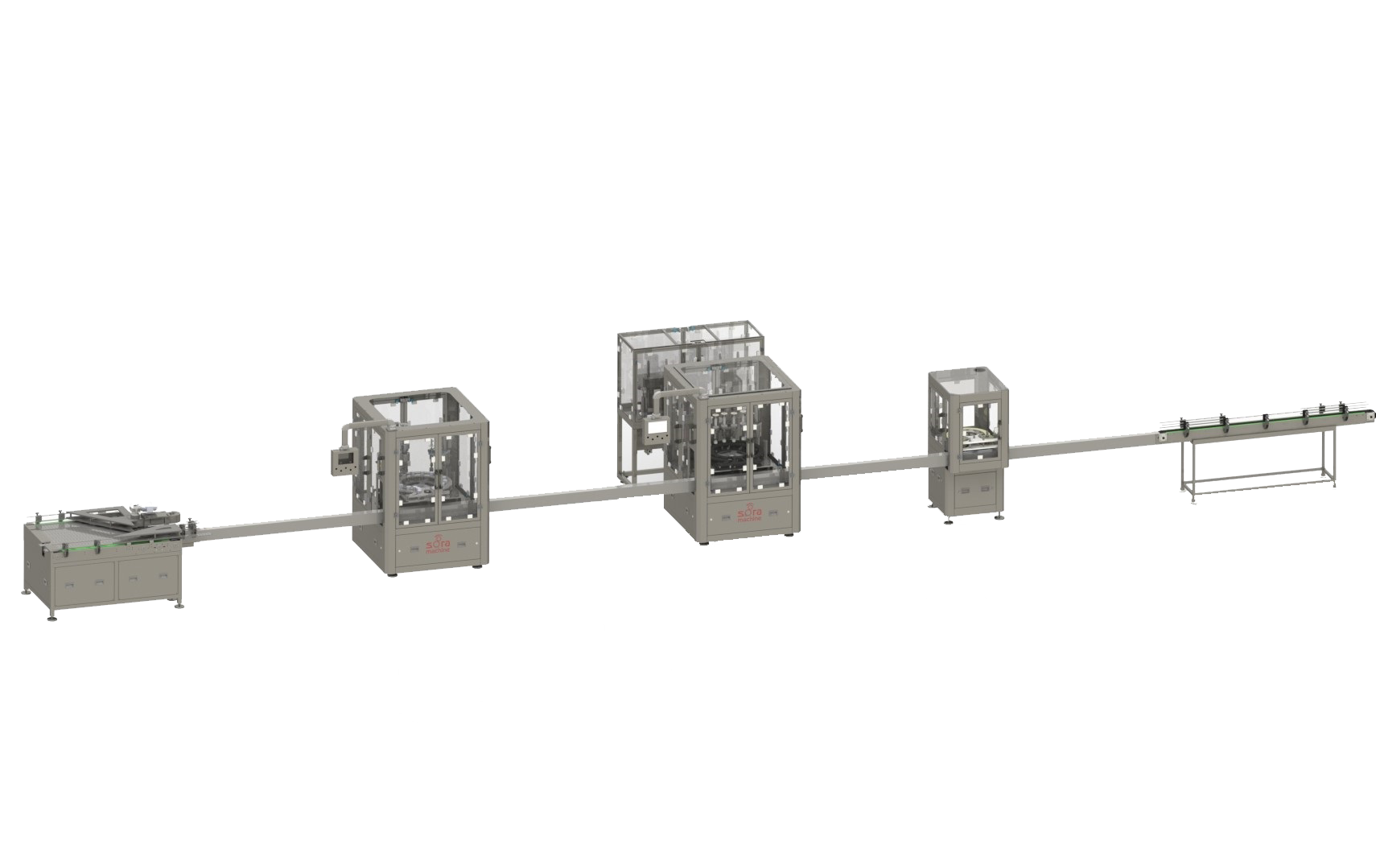

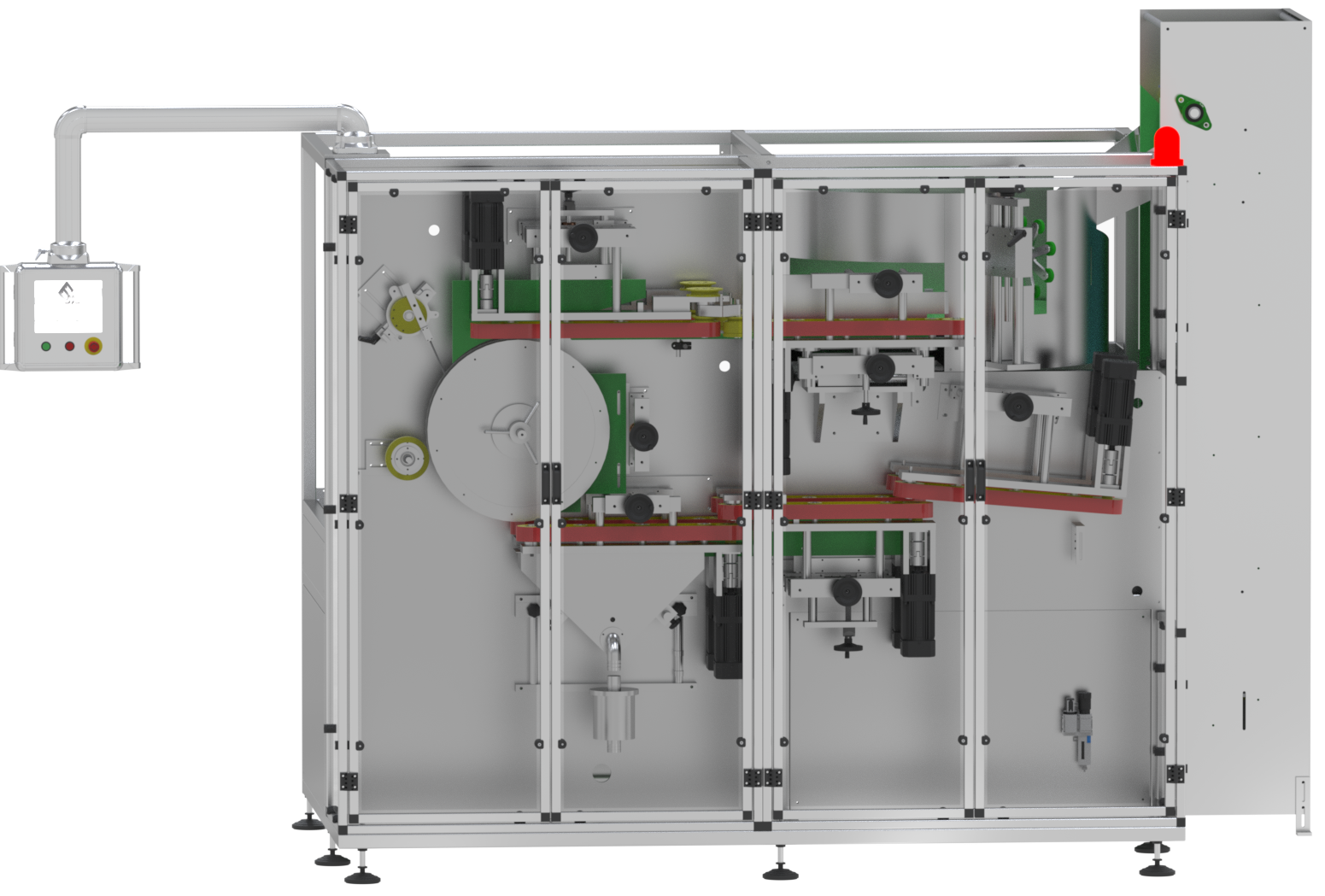

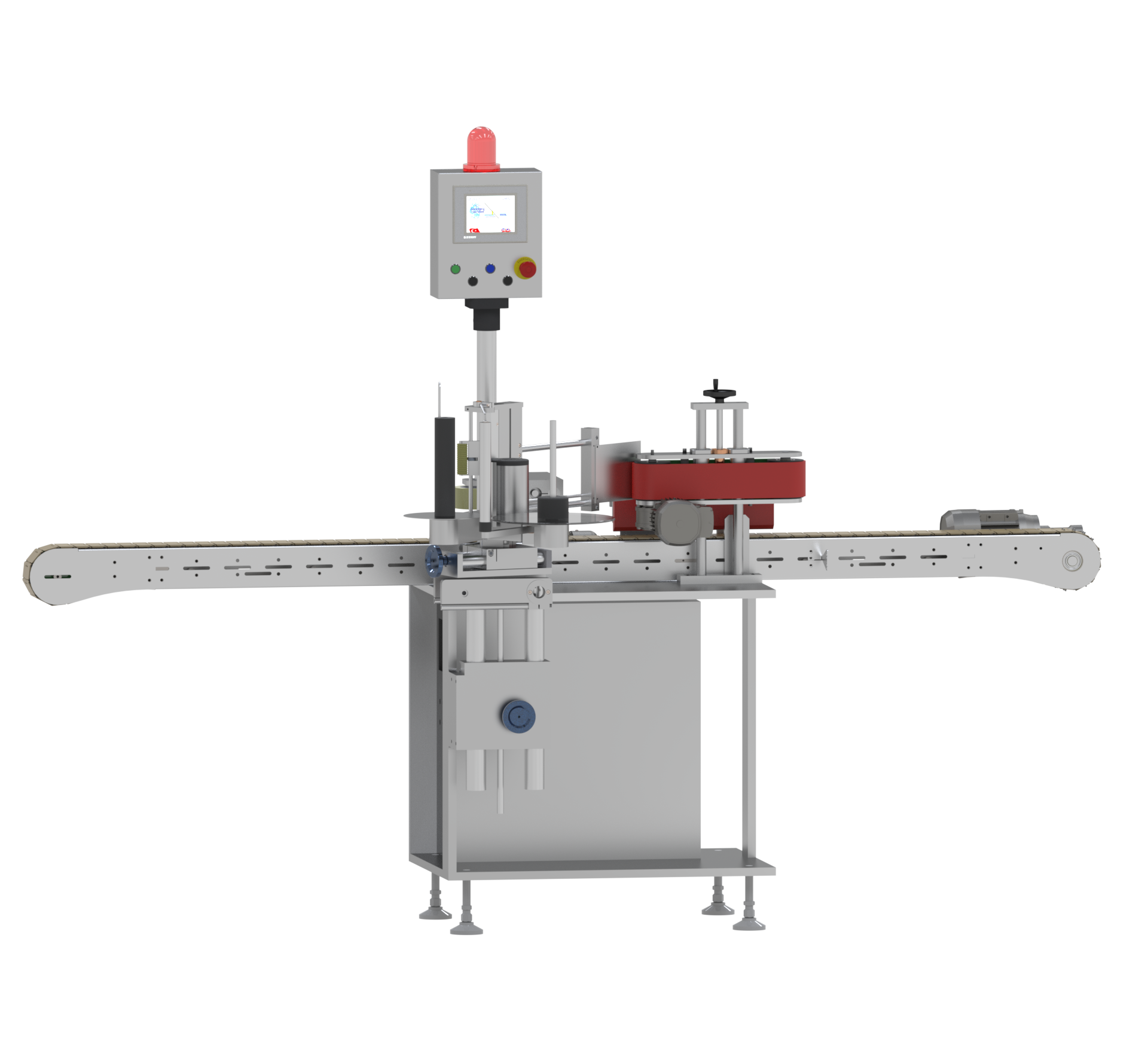

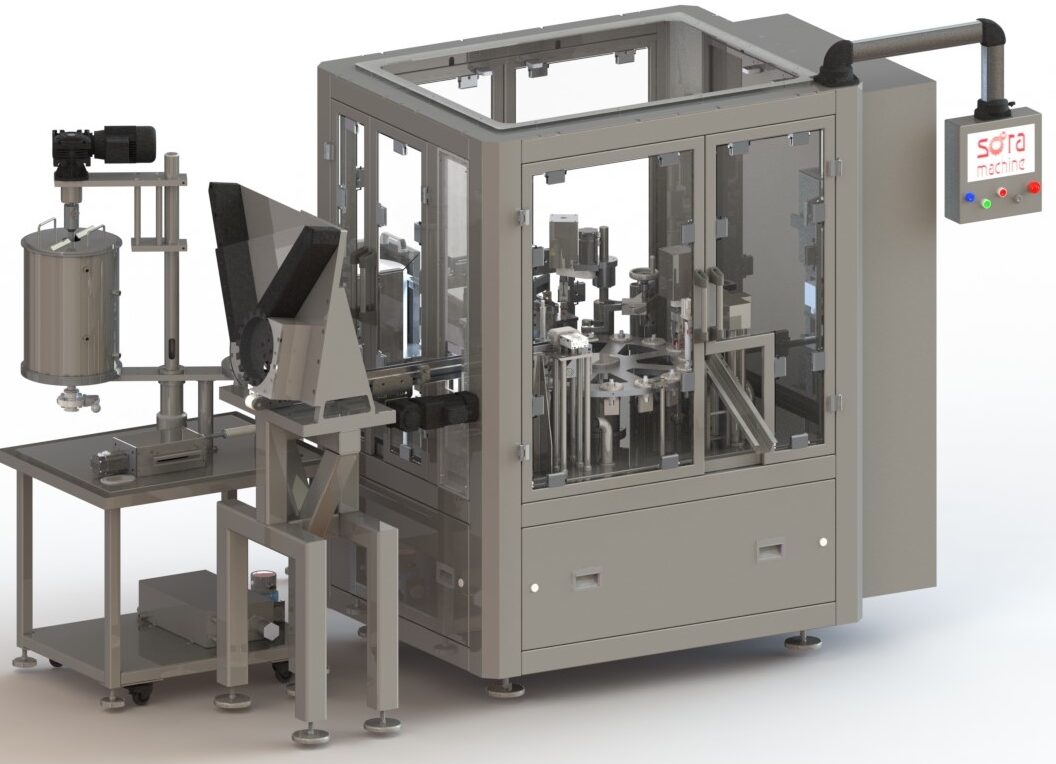

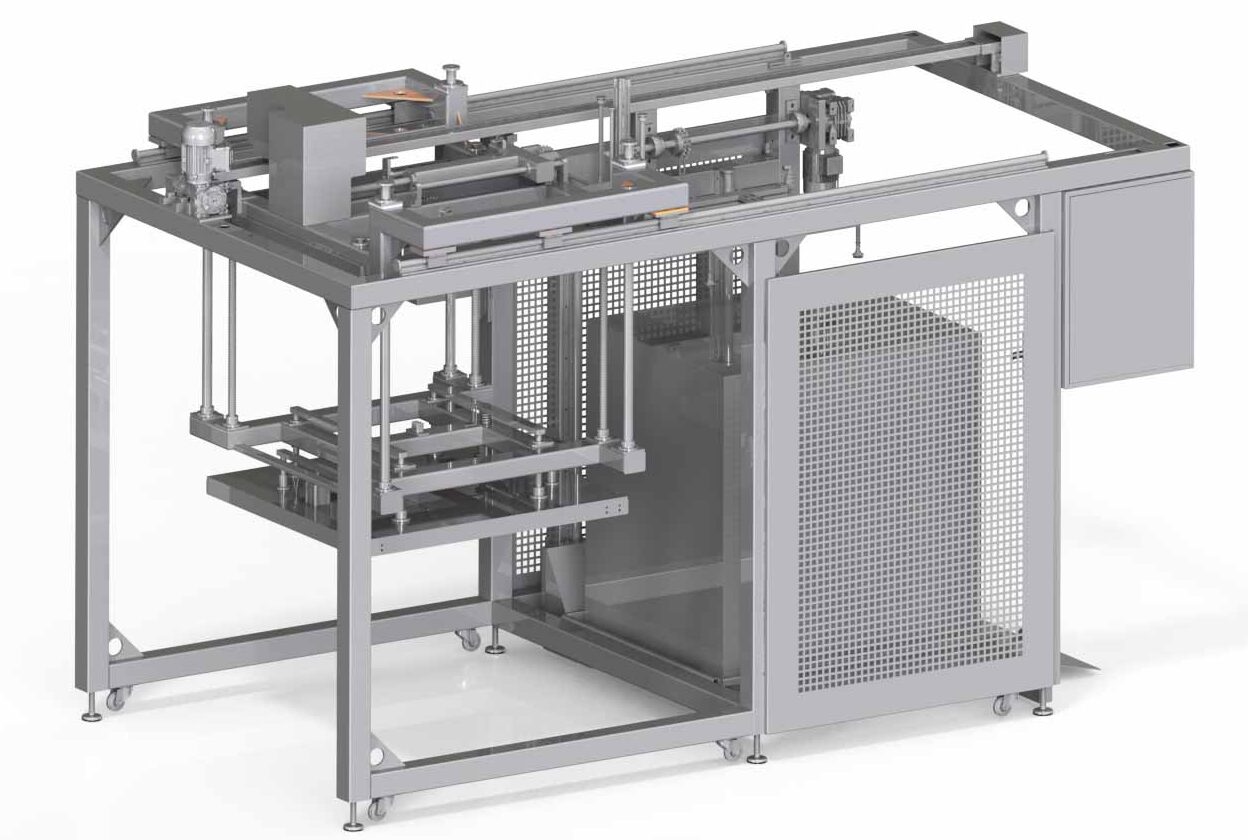

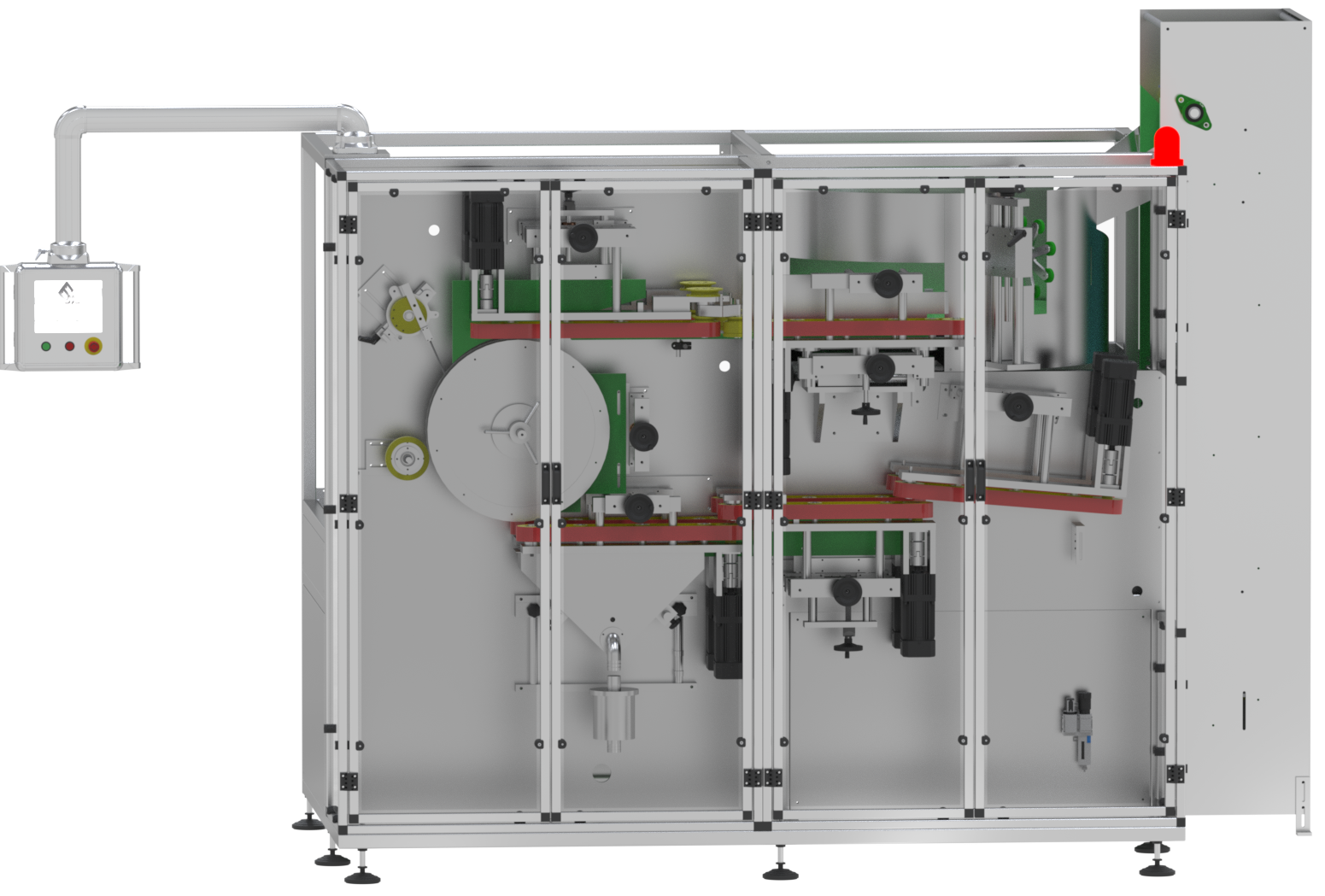

ALL- MAK UP TO 40 CPM Full Automatic Lines

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

- Product contact parts: AISI 316 or AISI 304 (quoted based on AISI 304)

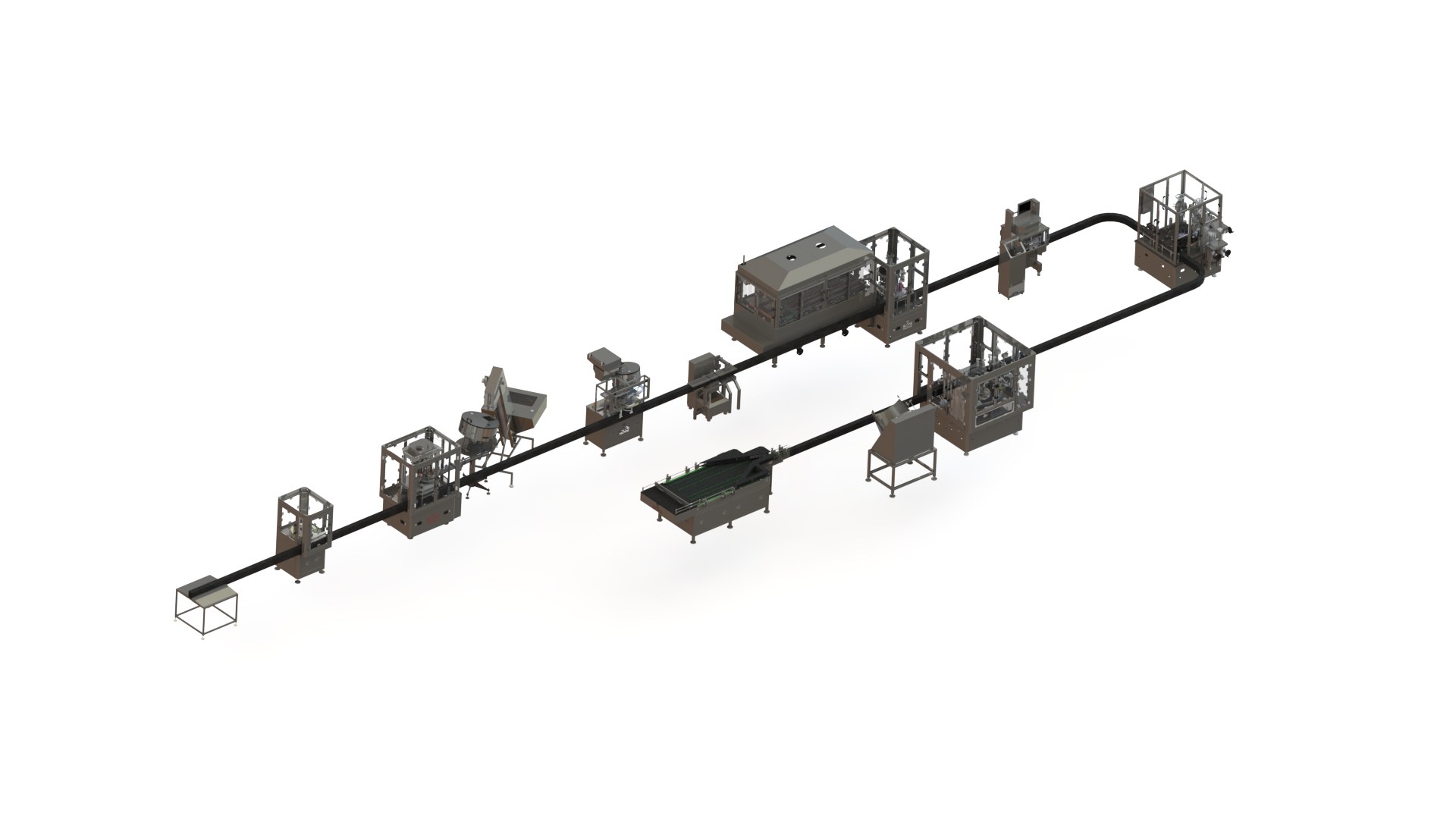

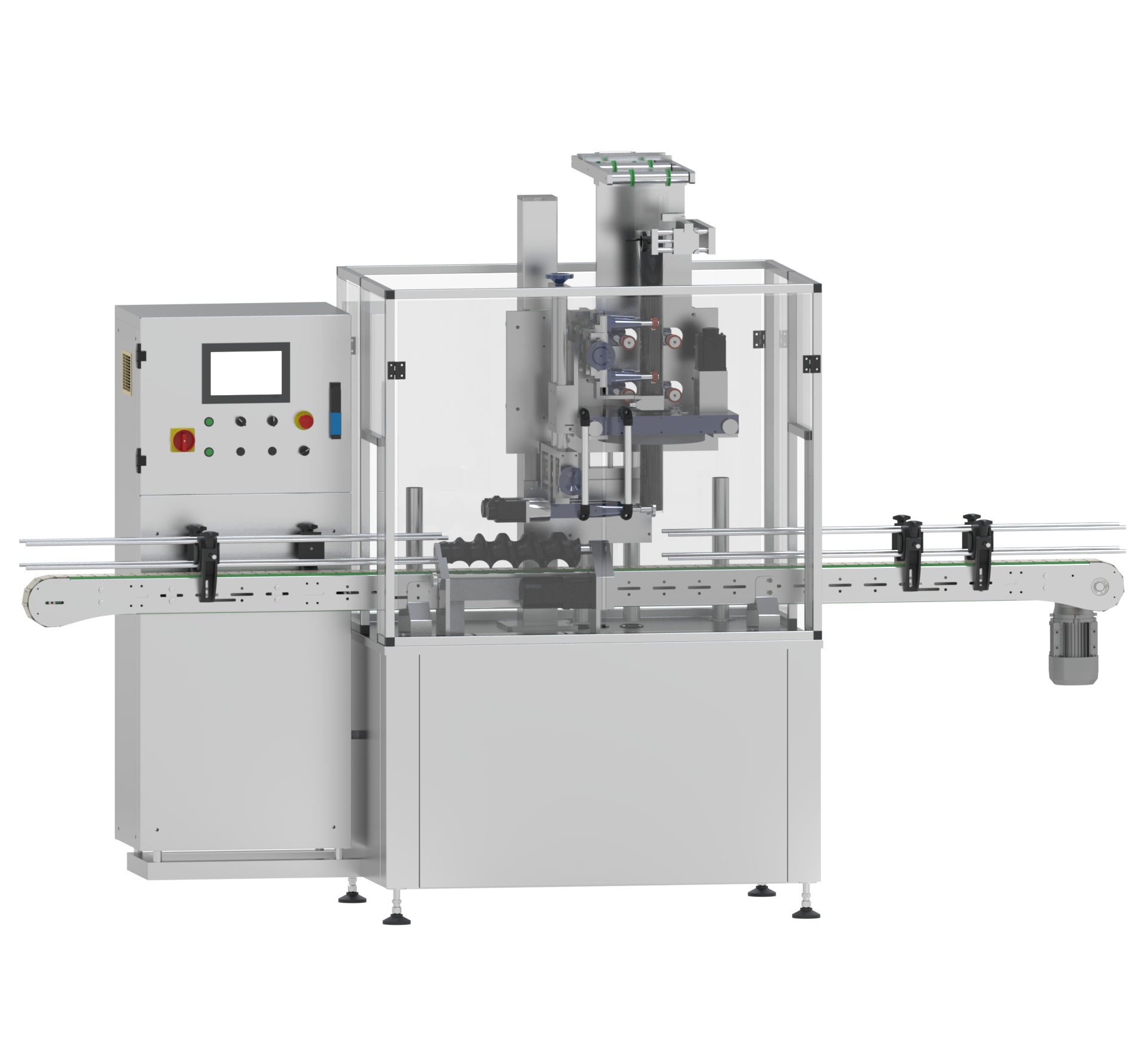

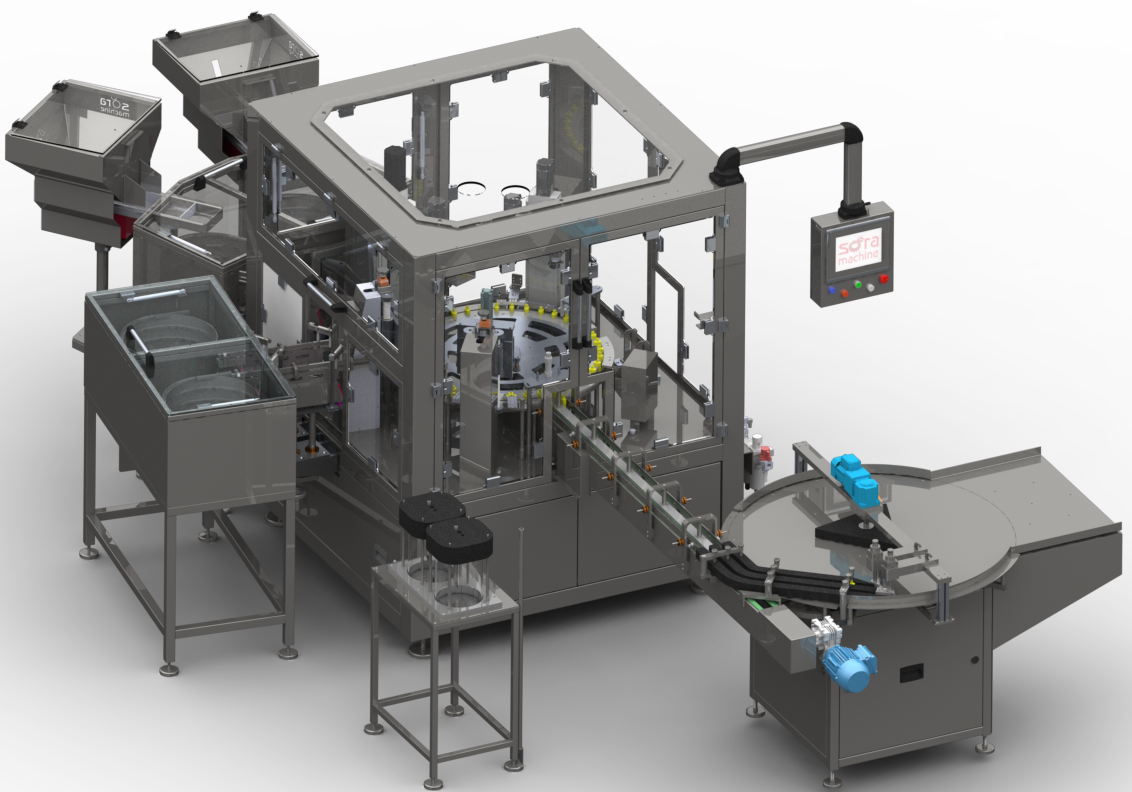

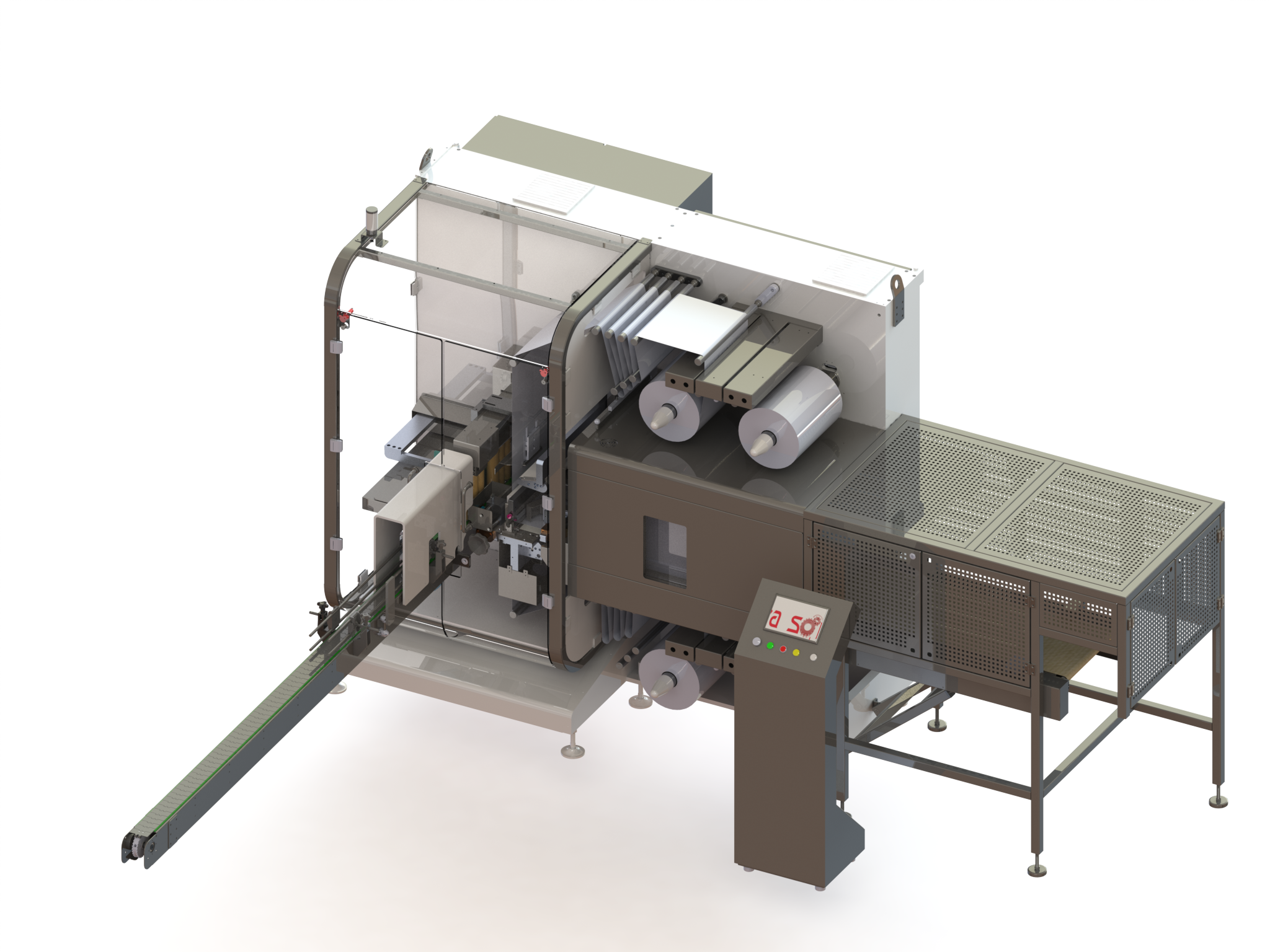

SIN-MAK UP TO 60 CPM Full Automatic Lines

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Scrolls, change parts and plastic covers on guide rails are anti-static

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

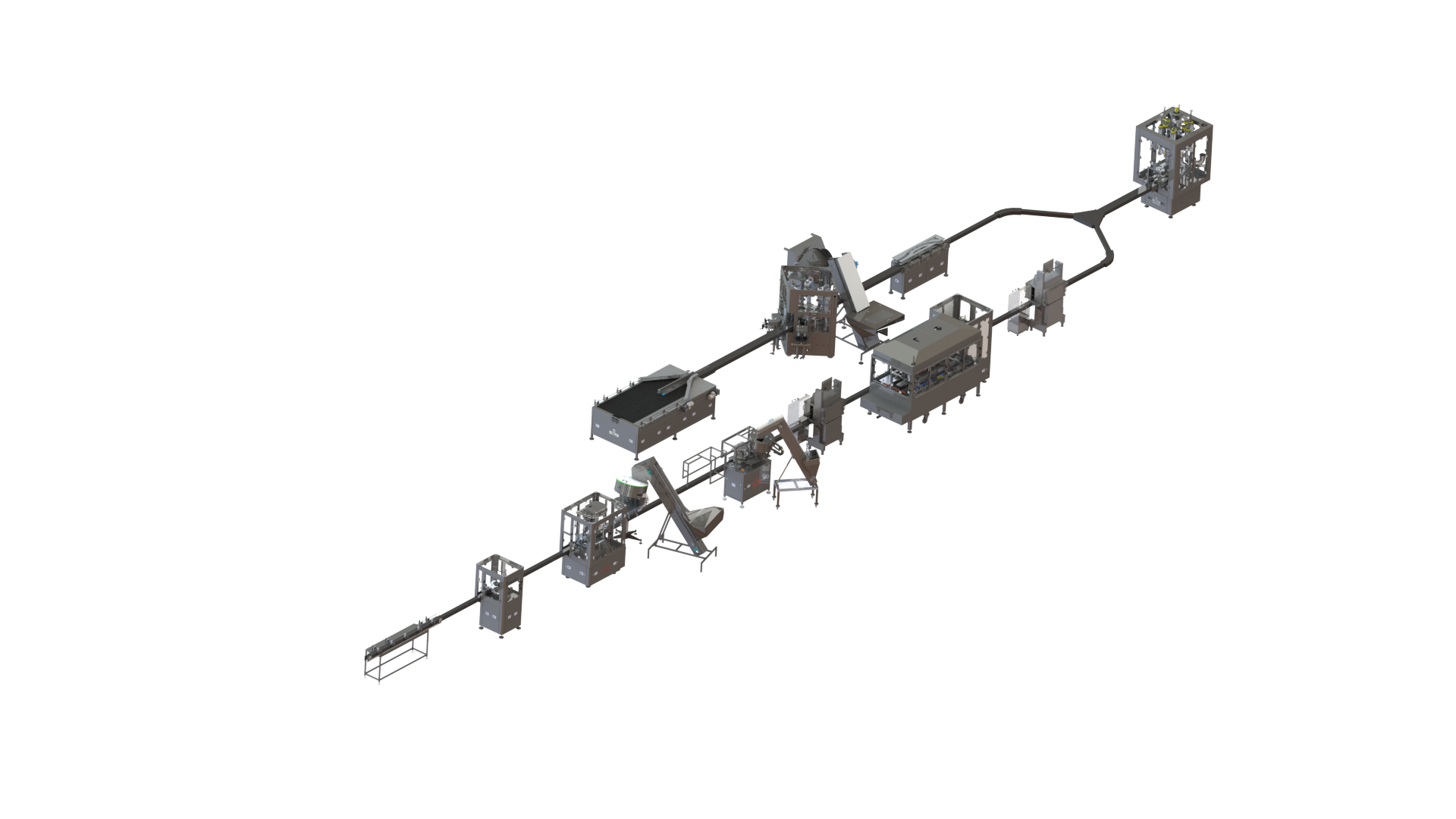

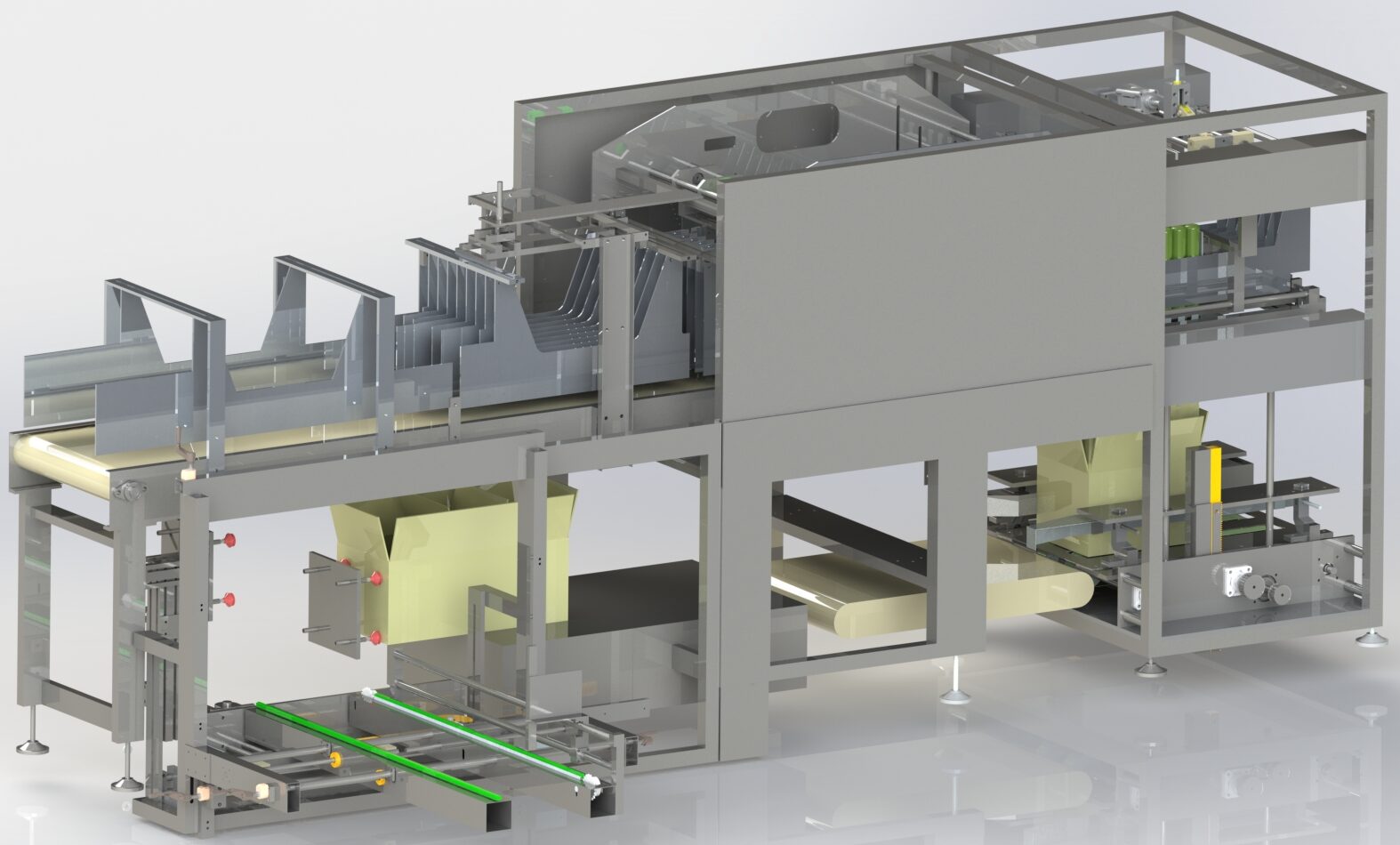

DUB-MAK UP TO 85 CPM Full Automatic Lines

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

- Product contact parts: AISI 316 or AISI 304 (quoted based on AISI 304)

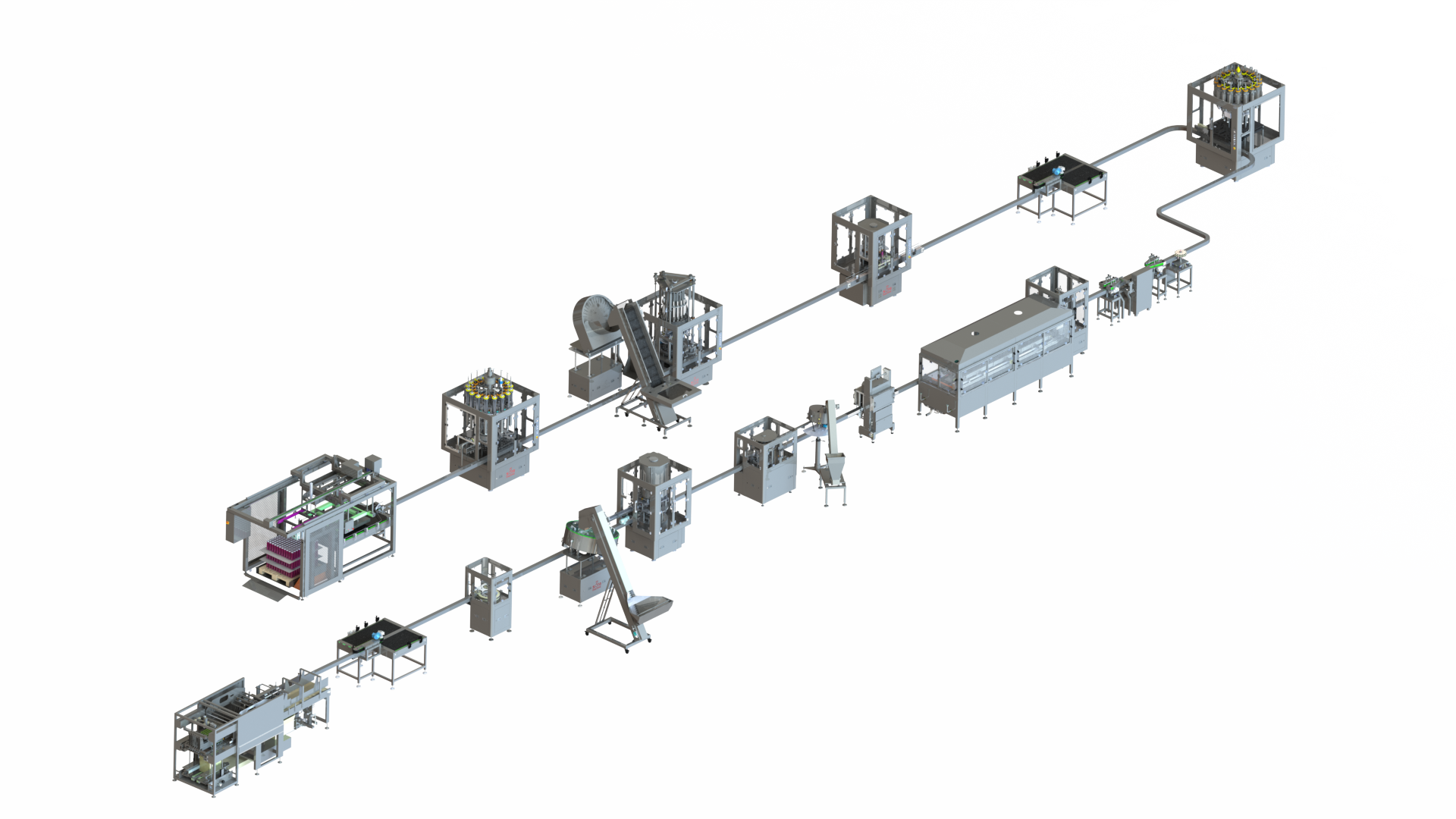

TWIN-MAK UP TO 120 CPM Full Automatic Lines

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Scrolls, change parts and plastic covers on guide rails are anti-static

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

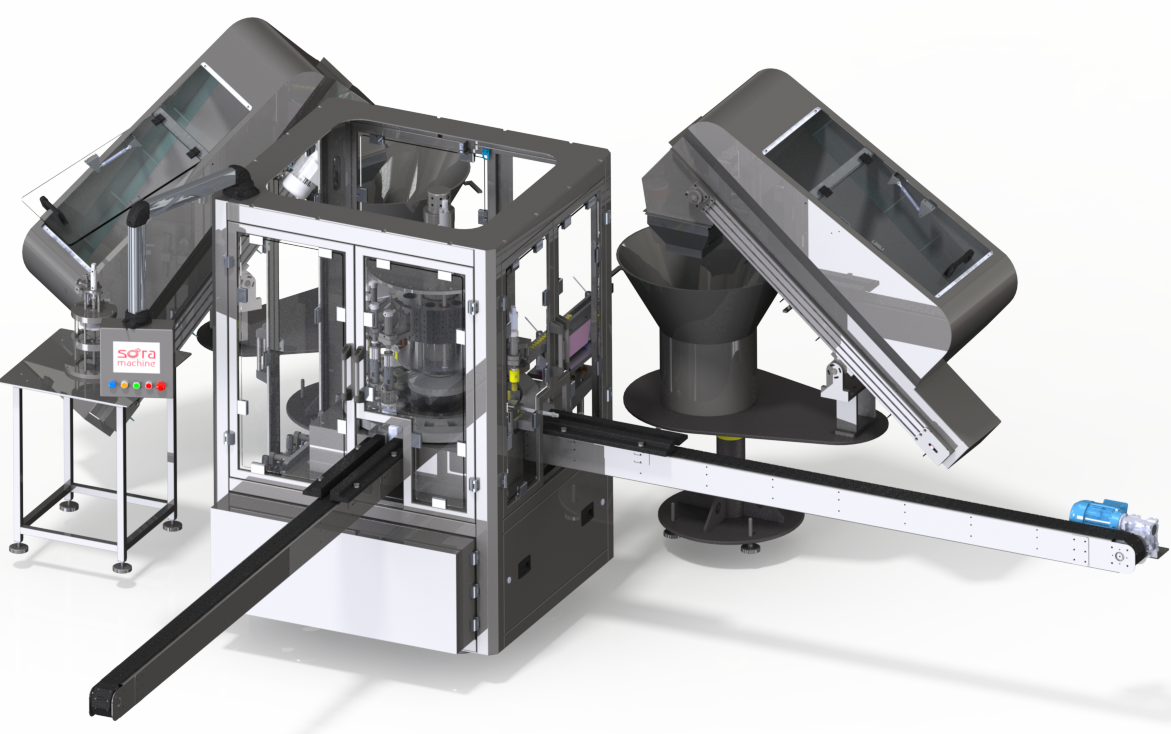

MONO-MAK 120 TO 250 CPM Full Automatic Lines

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

- Product contact parts: AISI 316 or AISI 304 (quoted based on AISI 304)

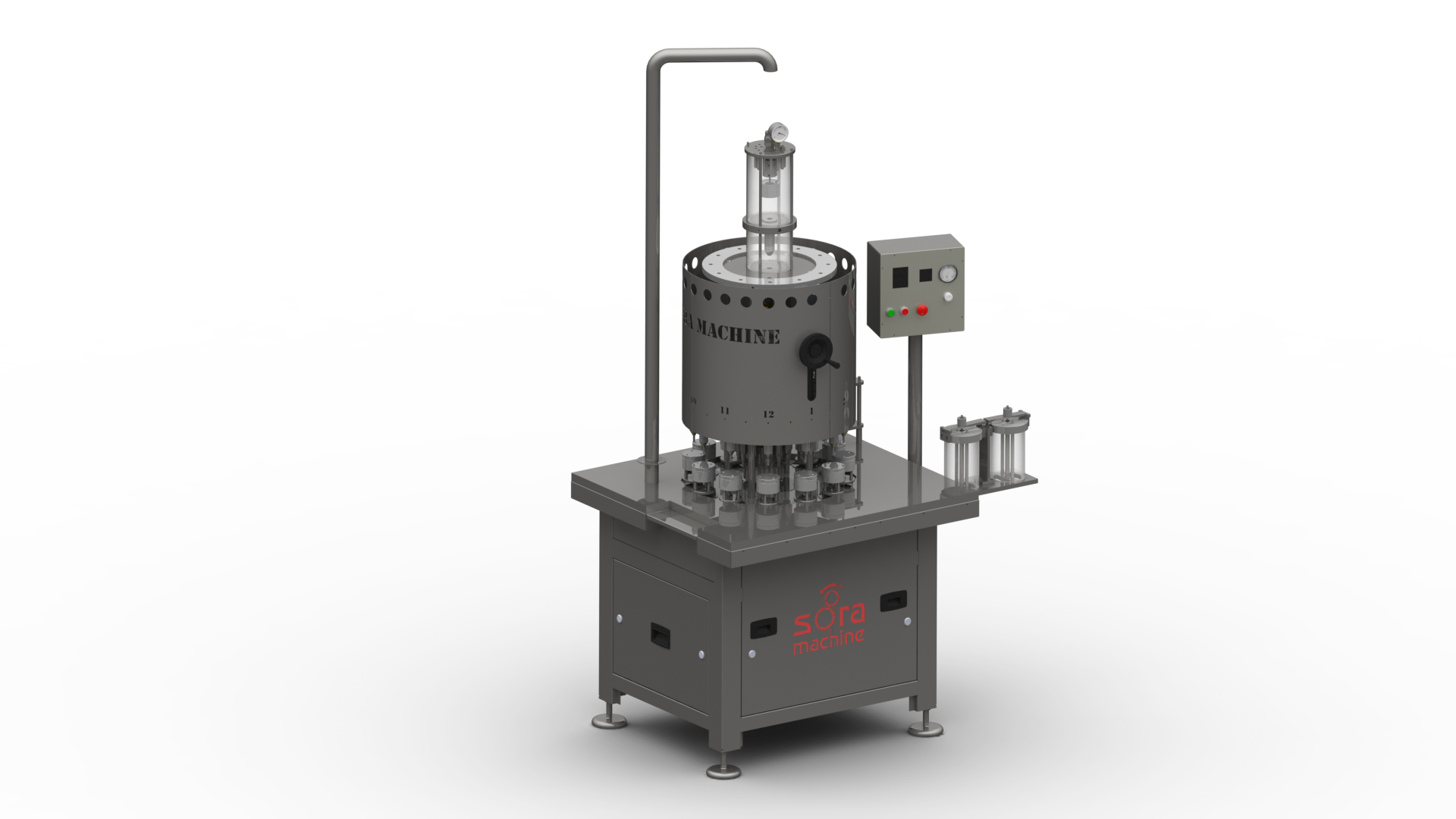

ROT-MAK 170 TO 300 CPM Full Automatic Lines

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

- Product contact parts: AISI 316 or AISI 304 (quoted based on AISI 304)

Purpose of Semi-Automatic BOV Laboratory Equipment

Semi-automatic Bag-on-Valve (BOV) laboratory equipment is used for small-scale production and R&D studies. This technology is particularly favored in pharmaceutical and medical products for its sterility, extended shelf life, and safety benefits. It offers an ideal solution for formulation testing, sample production, or pilot series studies.

Advantages of the BOV System in a Laboratory Setting

Implementing the BOV system on a laboratory scale provides manufacturers with the following benefits:

- Sterile filling: The product and gas do not come into contact with each other.

- Delayed spoilage: Product shelf life is extended because it’s isolated from air.

- 360° spray capability: Ensures ease of use.

- Increased formulation freedom: Allows for production without preservative additives.

Semi-automatic BOV equipment makes these advantages accessible even for low-volume productions.

Technical Specifications

The Semi BOV Lab Equipment developed by Sora Machine stands out with its user-friendly design, compact structure, and high precision. Its technical specifications are as follows:

| Feature | Description |

|---|---|

| Application Type | Semi-Automatic BOV Filling |

| Compatible Packaging | Cans with BOV valves |

| Filling Capacity | 8 – 10 cans per minute (based on 150 ml) |

| Filling Volume Range | 50 – 250 ml |

| Material | AISI 304 and AISI 316 Stainless Steel |

| Usage Area | Laboratory, pilot production, testing environment |

| Operator Input | Manually controlled valve and filling systems |

Suitable Product Groups for This System

Semi-automatic BOV laboratory equipment is particularly preferred in the following sectors:

- Medical spray products (antiseptics, wound sprays)

- Pharmaceutical solutions (nasal sprays, inhaler products)

- Cosmetic products (thermal water, facial sprays)

- Food supplements and aromatherapy

These systems are suitable for working with both water-based and oil-based formulations.

How a Semi-Automatic BOV System Works?

The basic operation of the system consists of three main steps:

- Valve placement: The operator places the can with the valve into the hopper.

- Product filling: The liquid product is filled into the inner bag, isolating it from the external environment.

- Gas filling: The area outside the valve is filled with propellant gas.

All these operations are performed within a manually controlled system, supported by precise sensors.

How This System Can Be Integrated into Larger Lines?

Semi-automatic systems, thanks to their modular structure, can be integrated into larger automation lines when needed. In later production processes, they can work together with the following machines:

- Fully automatic BOV filling lines

- Gas filling machines (propellant)

- Valve placement and crimping units

- Labeling and coding machines

Sora Machine’s solutions offer flexibility suitable for scalable production goals.

CE Certification and Operator Safety

All laboratory and production equipment from Sora Machine have CE certification. Semi-automatic BOV lab systems are also equipped with the following safety measures:

- Safety valves against overpressure

- Operator protection shield

- Easy-to-clean surfaces

- Warning systems against mechanical failures

This structure guarantees both user health and product safety in a laboratory environment.

What Sora Machine Offers in This Field?

Sora Machine is not just an equipment manufacturer; it also contributes to manufacturers with laboratory solutions, production consultancy, and R&D support. Machines are supported by features such as GMP-compliant production, remote technical support, and spare parts access. Additionally, customized system designs can be made for specific needs.

Who Are Semi-Automatic Aerosol Filling Machines Ideal For?

Semi-automatic aerosol filling machines are specifically designed for companies conducting new product tests in a laboratory setting, performing pilot production runs, or those with limited production capacity. They are frequently chosen in the following areas:

- Personal care and cosmetic products (e.g., deodorants, hair sprays)

- Industrial spray solutions

- Pet care and medical products

- Seasonal or special series productions

These machines deliver high precision and ease of use, even for low-volume production needs.

What Are the Technical Specifications of the Semi-Automatic System?

The semi-automatic filling machine model stands out with its user-friendly interface, stainless steel body, and flexible format compatibility. Here’s a summary of its technical details:

| Feature | Detail |

|---|---|

| Filling Volume | 5 – 200 ml |

| Can Diameter | Ø35 – 65 mm |

| Can Volume | 100 – 750 ml |

| Output | 8 – 10 cans per minute (based on 150 ml) |

| Material | AISI 304 and AISI 316 Stainless Steel |

| Operation Type | Manual valve-controlled semi-automatic system |

| Accuracy | ± 1% |

What Advantages Does the 6-Head Propellant Filling Machine Offer?

For manufacturers looking to scale beyond semi-automatic systems, Sora Machine offers a 6-head propellant filling machine that combines high speed with robust safety standards. This system can fill up to 30 cans per minute and is fully compatible with various gas types, including LPG and DME.

Technical Specifications:

| Feature | Description |

|---|---|

| Number of Nozzles | 6 |

| Filling Capacity | Up to 30 cans per minute |

| Gas Compatibility | LPG, CO₂, DME, etc. |

| Construction Material | Fully stainless steel (316/304) |

| Safety System | Pressure-controlled valve and protection systems |

| Integration Capability | Compatible with automatic valve insertion and crimping machines |

What Underpins Sora Machine’s Design Philosophy?

Sora Machine is not just a machine manufacturer; we are a partner that provides complete production solutions. Our machines are designed with:

- Easy-to-clean construction for hygienic production.

- Fast and simple format changes.

- CE-compliant safety systems for operator protection.

- Support from advanced technical service and remote assistance options.

All our products are developed in full compliance with GMP and ISO standards.

What is a Manual Water Bath and What Laboratory Applications is it Used For?

A manual water bath is a fundamental piece of equipment in laboratory settings, used to provide controlled temperatures. It’s particularly effective for keeping heat-sensitive samples stable, performing chemical reactions, or conducting viscosity tests, among many other processes. This equipment is widely favored in industries such as cosmetics, chemicals, food, and pharmaceuticals, especially in aerosol filling technologies. It makes laboratory processes safer due to its precise heat control and practical usability.

Why Choose a Manual Water Bath?

Laboratory-type water baths, especially manual models, offer flexibility to businesses engaged in low-volume production or R&D. Unlike digitally controlled systems, a manual water bath gives the user direct temperature adjustment and intervention capabilities. This makes it much easier to make immediate changes during experimental work or to observe samples. It’s also an ideal solution for energy saving and long-lasting use.

What are the Technical Specifications of a Manual Water Bath?

The manual water bath developed by Sora Machine offers long-lasting use with its stainless steel body and allows for simultaneous heating of different sized samples thanks to its large internal volume. The device enhances laboratory efficiency with its precise heating system and user-friendly control panel. Because heat distribution is homogeneous, there are no temperature differences between samples, which increases the reliability of test results.

Which Sectors Should Use a Manual Water Bath?

Sora Machine’s manual water bath is specifically designed for companies conducting R&D. These baths play a significant role in the pre-preparation processes of aerosol filling systems, as well as in the formula analysis of products like creams, lotions, or sprays. Furthermore, manual water baths are indispensable in drug development laboratories, cosmetic production facilities, chemical substance testing centers, and university research laboratories.

How Precise is Temperature Control with a Manual Water Bath?

Sora Machine’s manual water bath allows the operator to manually set the desired temperature range. This manual system enables quick attainment of precise temperature values required for specific tests and maintains stability. Homogeneous heat distribution prevents temperature deviations during testing, ensuring reliable results. Temperature monitoring is facilitated by easily observable control indicators.

How Does a Manual Water Bath Integrate with Aerosol Filling Systems?

Sora Machine’s manual water bath is specifically designed to be compatible with laboratory-type aerosol filling systems. It plays a critical role in sample preparation, product stability tests, and pre-filling preparation stages. The water bath can be directly integrated into the filling process to optimize product viscosity, stabilize formula content, or bring the product to the appropriate filling temperature.

What Should Be Considered When Using a Manual Water Bath?

For safety and efficiency during use, certain points should be considered. Firstly, the device should be cleaned before and after each use, and the water should be changed regularly. The surface where the device is placed must be flat and dry. Users should not exceed the maximum water level and should never operate the device empty. These precautions both extend the device’s lifespan and increase user safety.

Why Should You Buy a Manual Water Bath from Sora Machine?

Sora Machine successfully applies its years of experience in industrial and laboratory-type filling systems to its complementary equipment, such as manual water baths. Manual water baths produced to high-quality standards stand out with their durable material structure, precise control mechanism, and user-centric design. Sora Machine’s after-sales technical support service is also a reason to choose them. With its engineering approach offering customized solutions, Sora Machine optimizes your laboratory processes while guaranteeing your safety.

What Is a Manual Water Bath and Why Is It Used in Aerosol Safety Testing?

A manual water bath is a safety device used in aerosol production lines to test containers for leaks by submerging them in heated water. When aerosol cans are pressurized, even a micro-leak can compromise safety. The manual water bath method ensures that faulty or leaking containers are identified before they proceed to packaging or distribution.

The test involves immersing filled cans in a water tank, typically heated to a specific temperature. If bubbles are observed escaping from the container, it indicates a leak. This visual method, although simple, is highly effective and widely accepted in global safety standards.

How Does the Manual Water Bath Leak Test Work?

The manual leak test by water bath follows a straightforward yet essential process:

-

Cans are filled and sealed: After the filling and crimping stages, pressurized cans are transferred to the water bath.

-

Submersion in heated water: The water is maintained at a controlled temperature, usually between 50°C to 55°C, to simulate stress conditions.

-

Visual inspection: Operators watch for rising air or gas bubbles, which indicate leakage from the canister or valve.

-

Manual removal of defective units: Any leaking containers are removed from the line for disposal or rework.

This method is not only cost-effective but also reliable for small to medium-scale aerosol production environments.

Why Is Leak Testing Crucial in Aerosol Filling Lines?

Leak testing is a mandatory part of aerosol production due to the pressurized and often flammable nature of the contents. Even a tiny leak can result in:

-

Product loss and compromised fill accuracy

-

Safety hazards including fire or explosion risks during transport

-

Customer dissatisfaction and damage to brand reputation

-

Non-compliance with regulatory and transport standards such as ADR or DOT

Implementing a manual water bath test ensures that every can leaving the production line is safe, intact, and compliant with industry standards.

What Are the Advantages of Manual Water Bath Systems?

Manual water bath leak testing devices offer several benefits, especially for facilities operating with limited automation or custom product lines:

-

Cost-effective setup with no need for complex automation

-

Quick operator training and ease of use

-

Flexible design suitable for various aerosol can sizes

-

Reliable results when conducted by trained personnel

-

Compact footprint ideal for small production spaces

Although manual, these systems can be built from high-grade materials and integrated into semi-automated lines depending on operational needs.

What Safety Standards Do Manual Water Baths Comply With?

Sora Machine’s manual water bath safety devices are designed in accordance with globally recognized safety and manufacturing standards:

-

EN 15004 – for fire suppression systems using pressurized containers

-

ADR / DOT – transport compliance for dangerous goods

-

ISO aerosol filling standards – ensuring production traceability

-

CE marked components – to guarantee operational safety in the EU

Each unit is manufactured using corrosion-resistant stainless steel and temperature control systems that ensure repeatable, compliant testing performance.

What Are the Key Features of Sora Machine’s Manual Water Bath Systems?

Sora Machine designs and manufactures manual water bath safety devices with a focus on durability, safety, and user-friendly operation. Key features include:

-

Double-walled stainless steel tanks for thermal insulation

-

Adjustable temperature control for optimized leak detection

-

Ergonomic can holders to support quick loading and unloading

-

Drainage and overflow systems for safe water management

-

Optional air bubble sensors to assist visual inspection (for hybrid models)

Our systems are ideal for low-to-medium speed production environments that still demand high safety standards and full compliance.

When Should You Choose a Manual Water Bath Instead of an Automatic One?

While fully automatic water bath systems are ideal for high-speed production, there are scenarios where a manual water bath is more suitable:

-

Startups or small production runs

-

Specialty or limited-edition aerosol products

-

Pilot-scale manufacturing and R&D labs

-

Budget-conscious operations

-

Products requiring frequent line changes

Manual systems give manufacturers greater flexibility while maintaining essential safety testing processes.

How Does Sora Machine Ensure Operator Safety with Manual Water Bath Systems?

Although manual in operation, safety is never compromised. Sora Machine includes several features to protect operators:

-

Insulated tank surfaces to prevent heat exposure

-

Non-slip platforms and handles for safe handling

-

Emergency stop controls and overheat protection

-

Clear water level indicators to prevent overflows

-

Optional lid or cover options for increased safety

These systems are also designed to be easily cleaned and sanitized to support hygienic working conditions.

How Can Manual Water Baths Be Integrated Into an Existing Filling Line?

Sora Machine offers modular designs that allow the manual water bath system to be placed:

-

Directly after the filling/crimping stage

-

In a standalone QC (quality control) station

-

At batch testing points for periodic inspection

-

With optional conveyor feeds for semi-automation

Depending on the layout and speed of your filling line, Sora’s engineering team can recommend the most effective configuration.

What Is a Checkweigher and Why Is It Critical in Aerosol Production?

A checkweigher is an automated system designed to verify the weight of products during production. In aerosol filling lines, its role is to ensure each unit meets specified weight requirements before packaging. This is essential for regulatory compliance, cost control, and consistent product quality.

By identifying underfilled or overfilled products in real time, checkweighers help manufacturers avoid costly product recalls and maintain brand integrity. They also play a key role in minimizing waste and optimizing production efficiency.

How Does a Checkweigher Work?

Checkweighers operate by measuring the weight of individual items as they pass through a dynamic weighing platform—typically a belt conveyor with load cells integrated into the weighing section. The system captures the weight of each product, compares it to predefined limits, and then takes automated action:

-

Within weight limits: The product continues on the line.

-

Outside limits: The product is rejected and diverted from the line.

Modern checkweigher systems include touchscreen interfaces, programmable logic controllers (PLCs), and integration with SCADA or MES systems for production monitoring and reporting.

In Which Industries Are Checkweighers Commonly Used?

Checkweighers are vital across a wide range of industries where accuracy and compliance are critical:

-

Aerosol and Cosmetics: For deodorants, hairsprays, and body sprays

-

Pharmaceuticals: For pressurized metered-dose inhalers (MDIs) and liquid medications

-

Household Chemicals: For disinfectant sprays and air fresheners

-

Food & Beverage: For portion-controlled and packaged items

-

Automotive & Technical Products: For spray lubricants and maintenance aerosols

Especially in aerosol manufacturing, weight deviations can result in product failure or safety concerns. A robust checkweigher eliminates this risk.

What Are the Advantages of Integrating a Checkweigher in Aerosol Lines?

For aerosol filling systems, checkweighers deliver several operational and quality-related benefits:

-

Inline Quality Control: Each can is inspected instantly without slowing down the line

-

Reduced Material Waste: Incorrectly filled cans are automatically removed

-

Process Optimization: Feedback data helps identify filling issues upstream

-

Compliance Assurance: Ensures adherence to national and international weight regulations

-

Brand Protection: Prevents defective or non-compliant products from reaching the market

Sora Machine’s checkweighers are engineered for high-speed aerosol environments, offering precision and repeatability with minimal maintenance.

How Do Checkweighers Differ from Other Safety Devices?

While checkweighers are part of the safety devices in a production line, their function is distinct. Here’s how they compare to other common devices:

| Device Type | Main Function |

|---|---|

| Checkweigher | Weight control and rejection of faulty units |

| Leak Tester | Detects pressurized gas leakage in cans |

| Flame Tester | Ensures proper spray valve function |

| Pressure Tester | Verifies internal pressure against safety limits |

Checkweighers focus solely on ensuring that filled products meet target weight tolerances. They are best used in conjunction with other devices to build a complete, automated quality assurance system.

What Makes Sora Machine Checkweighers Stand Out?

Sora Machine offers advanced checkweigher systems tailored specifically for aerosol filling lines. Our units feature:

-

Stainless steel construction for hygienic and corrosion-resistant performance

-

High-precision load cells capable of handling fast-moving production lines

-

IP-rated protection against dust and moisture

-

Customizable rejection systems based on can size or product type

-

Integrated software for real-time weight data and production statistics

All units are compatible with existing Sora aerosol filling machines and can be adapted to fit various line configurations.

What Should You Consider When Choosing a Checkweigher?

Selecting the right checkweigher depends on your production specifications. Consider the following:

-

Speed Requirements: How many cans per minute must be checked?

-

Product Type: What are the dimensions, materials, and weights of your cans?

-

Accuracy Tolerance: What weight variation is acceptable?

-

Line Integration: Will the unit work seamlessly with your existing setup?

-

Environment: Is the production area humid, dusty, or exposed to cleaning agents?

Sora Machine offers both standard and customized solutions to meet these specific requirements.

Why Is Regular Maintenance and Calibration of Checkweighers Necessary?

To maintain consistent performance and legal compliance, checkweighers require periodic maintenance and calibration. Over time, mechanical wear, environmental conditions, or product buildup may affect weighing accuracy. Common risks of inadequate maintenance include:

-

False rejections or acceptance of defective units

-

Inconsistent data logging or reporting errors

-

Increased downtime due to undetected mechanical faults

Sora Machine provides after-sales support, calibration services, and spare parts to keep your checkweigher systems operating at peak efficiency.

How Do Checkweighers Support Digital Manufacturing Goals?

In a smart factory setting, checkweighers play a crucial role in process transparency and optimization. Integration with central data systems allows for:

-

Real-time production analytics

-

Batch traceability and defect tracking

-

Predictive maintenance based on machine behavior

-

Remote access and control

These capabilities align with Industry 4.0 initiatives, helping manufacturers reduce waste, improve accuracy, and enhance decision-making.

Checkweigher systems are indispensable for any high-volume, precision-driven production line—especially in aerosol manufacturing. Sora Machine delivers industrial-grade, user-focused checkweighers that guarantee accuracy, support automation, and minimize human error. With our expertise in integrated aerosol filling systems, we help you maintain full control over your product quality, regulatory compliance, and production efficiency.

What is a Leak Detection Device and What Does It Do?

A Leak Detection Device used in aerosol filling lines is a highly sensitive instrument that detects whether propellants or liquids contained within products are leaking.

Its primary purposes are to:

- Increase production safety

- Comply with legal safety standards

- Guarantee consumer safety

- Sustain production quality

What Production Speeds is it Compatible With?

The device is suitable for medium and high-capacity production lines.

Technical capacity:

- Maximum production speed: 150 cans/minute (150 CPM)

- Adaptation to different production speeds with fast transition modes

- Real-time detection and debugging system

What Can Sizes Does It Support?

The device is designed to be fully compatible with various aerosol can sizes used in different industries.

Compatible can dimensions:

- Maximum diameter: 80 mm

- Maximum height: 400 mm

- Easy transition thanks to an adjustable conveyor belt and sensor system

What is the Leak Detection Sensitivity?

Even the smallest leaks are detected by the system with high accuracy.

Detection sensitivities:

- Standard mode: 8×10−3 mbar l/s

- Sensitive mode: 2×10−3 mbar l/s

- Effective solution against micro-leaks

- Advanced sensor architecture

What are the Electronic System and Interface Features?

The device is equipped with smart electronic systems suitable for modern production lines.

Control and interface details:

- Automation compatibility with 24 V DC I/O signals

- Control panel with HMI screen (wall-mounted / freestanding option)

- Remote access and diagnostic support

- Data logging and production report generation

- Error warnings and alarm system

In What Environmental Conditions Does It Operate?

It has suitable environmental tolerances for safe and long-term use.

Operating conditions:

- Temperature: 10−40 °C

- Electrical supply: 110/220 V AC blower

- Air requirement: 4 bar dry, oil-free compressed air

- Safety certification: ATEX Zone II (suitable for explosive atmospheres)

Is It Easy to Integrate into a Production Line?

With its modular structure, it can be easily adapted to different production lines.

Integration features:

- Minimum required space: ~1 meter

- Compact and space-saving design

- Fast installation into existing filling lines

- User-friendly sensor and carrier compatibility

How Are Faulty Products Separated?

Products detected with leaks are automatically removed from the production line.

Reject box features:

- 304-grade stainless steel construction

- Easy emptying with a drain valve design

- Hygienic and safe waste management

- Allows the operator to exclude the product without direct contact

What Additional Features Make the Device Stand Out?

The device not only detects but also provides infrastructure for advanced analysis.

Extra functions:

- Infrared gas detector

- ATEX-approved emergency stop button box

- Software logging and production data analysis

- Archiving system for product traceability

In Which Sectors Can It Be Used?

The Leak Detection Device can be actively used in many sectors where aerosol production is intensive:

- Cosmetics industry (deodorants, hairsprays, etc.)

- Household cleaning products (surface cleaners, air fresheners)

- Industrial maintenance products

- Medical aerosol solutions

- Automotive industry (lubricant sprays, engine cleaners)

Why Should a Leak Detection Device Be Preferred?

The Leak Detection Device elevates aerosol production line safety and quality to a new level.

Key benefits:

- High-sensitivity leak detection

- Fully integrated control and monitoring system into the production process

- Modular design that increases operational efficiency

- Safety certifications suitable for explosive atmospheres

- Fully automatic error management with reject systems

Thanks to this device, you can eliminate leak risks in your production line, ensuring that every product reaching the consumer is safe and flawless.

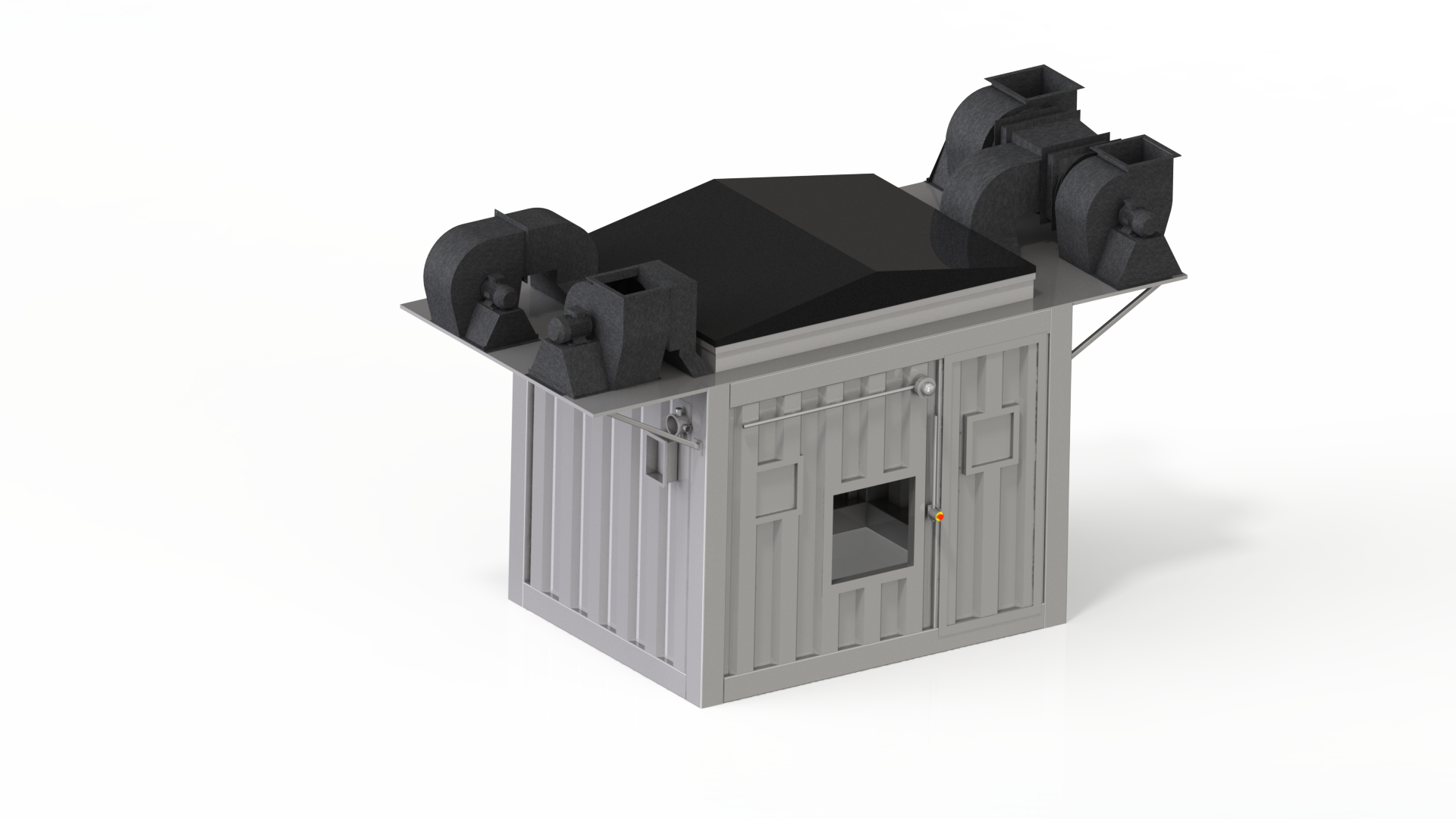

What is a Gas House and Why is It Necessary in Aerosol Filling Lines?

A Gas House is a specialized safety cabinet used in aerosol filling lines that ensures the controlled, safe, and isolated processing of hazardous, flammable, and volatile gases. It is vital in systems that operate with propellant gases like LPG, providing protection against leakage risks. Sora Machine’s Gas House solution is designed in compliance with EN14470-1 and ATEX standards, elevating both operator and environmental safety to the highest level.

Which Safety Standards Does the Sora Machine Gas House System Meet?

The Gas House is manufactured in accordance with global safety regulations, especially European directives:

- ATEX Zone Class I and II compliant structure

- EN14470-1 standards for gaseous environment control

- Stainless steel body for fire and corrosion resistance

- Ventilation and exhaust systems for maximum gas evacuation

- Explosion-proof pressure relief valves

- Automatic monitoring infrastructure with gas detectors

Thanks to this equipment and design, the system creates a safe operating environment in production facilities.

How Is the Gas House System Integrated into Aerosol Filling Lines?

Sora Machine’s Gas House solution can be integrated into aerosol filling lines in a modular fashion. The system is compatible with the following operational areas:

- 6-head or 12-head filling systems

- Laboratory-type semi-automatic systems

- Fully automatic high-capacity lines

The Gas House is typically positioned in the gas cylinder section of the filling line, and gas is supplied to the filling line via special connections. Throughout this process, parameters such as internal pressure, gas leakage, and temperature are continuously monitored.

What Advantages Does Using a Gas House Offer?

Using a Gas House provides significant advantages not only in terms of safety but also in terms of production line continuity and legal compliance:

- Minimizes leakage risks, preventing industrial accidents.

- Ensures operator and equipment safety, reducing maintenance costs.

- Complies with local and international safety standards.

- Centralizes gas management, enabling systematic monitoring.

- Provides the ability to respond early to fire and explosion risks.

Additionally, with this unit integrated into the automation system, automatic shutdown and alarm systems are activated whenever a gas-related risk is detected on the production line.

In Which Production Areas Is the Gas House System Preferred?

Gas House units are preferred not only in the aerosol sector but also in other gas-based production processes:

- Cosmetic product manufacturing (deodorant, hair spray, perfume)

- Medical aerosol products (MDI solutions)

- Household care products (room spray, surface cleaner)

- Industrial lubricant and solvent-based spray production

Especially in lines where propellant filling is intensive, safety solutions like the Gas House are indispensable.

BOV MAK: The Meeting Point of High Efficiency and Hygiene

BOV MAK is an advanced aerosol filling system based on innovative Bag-On-Valve (BOV) technology, integrable into modern production lines. By physically separating the product from the propellant, it maximizes both content safety and user satisfaction. Developed by Sora Machine, BOV MAK is safely used in many sectors, from cosmetics to health, cleaning to food.

Key Advantages of Bag-On-Valve Technology

Superior Hygiene and Protection

Thanks to the valve system inside the bag, the product does not come into contact with the inner surface of the metal can or the propellant. This structure preserves the integrity of the product even in applications requiring sterility. At the same time, quality problems such as microbial contamination and oxidation are completely eliminated.

One Hundred Percent Product Usage

The unique structure of the BOV system prevents the product from being trapped inside the can. The user can consume the product until the last drop. This not only increases customer satisfaction but also facilitates recycling processes.

Sustainable and Environmentally Friendly

Unlike classic aerosol systems, BOV technology can work with environmentally friendly gases and minimizes the use of preservatives in the product content. The separation of gas and product also ensures that the product packaging is easily recyclable.

Technical Excellence of BOV MAK

Developed with the engineering power of Sora Machine, BOV MAK machines are optimized for high-performance production.

Automatic Control and Precise Filling

Thanks to the PLC-controlled system infrastructure, all parameters such as filling volume, pressure, and speed are managed digitally. This minimizes the error rate while making the production process extremely stable and safe.

High Production Capacity

BOV MAK can fill 20 to 80 cans per minute, depending on the model. This flexibility makes it suitable for both small-scale and large-volume production facilities.

Modular and Flexible Design

BOV MAK systems, which can be supported by optional modules, can be easily integrated into existing production lines. This shortens the return on investment period and increases production capacity.

Application Areas: Multi-Sector Power

Cosmetic and Personal Care Products

Ideal for products such as deodorants, hair mousses, shaving gels, and care sprays. By preventing the product from coming into contact with air, the shelf life is extended, and formula stability is maintained.

Pharmaceutical and Medical Products

An excellent solution for sensitive products such as nasal sprays, wound care solutions, and inhalers. BOV systems make a difference in these areas where sterility and dosage accuracy are critical.

Food and Dietary Supplement Products

Contents such as spray oils, food additives, and aromatic products are offered to consumers without compromising freshness.

Industrial and Household Cleaning Products

Provides smooth spraying and controlled consumption in cleaning products such as disinfectants, surface cleaners, and glass sprays.

Why BOV MAK?

- Design Compliant with International Standards

- Stable Performance Even at High Production Speeds

- User-Friendly Control Interfaces

- Low Maintenance Needs and Long Lifespan

- Strong After-Sales Support with Sora Machine Expertise

With BOV MAK, Sora Machine offers manufacturers not just a machine; but also high-quality production, less waste, and greater customer satisfaction. This technology, which combines local production power with global standards, is an investment opportunity that will take your brand one step further. Contact Sora Machine to take advantage of these technologies!

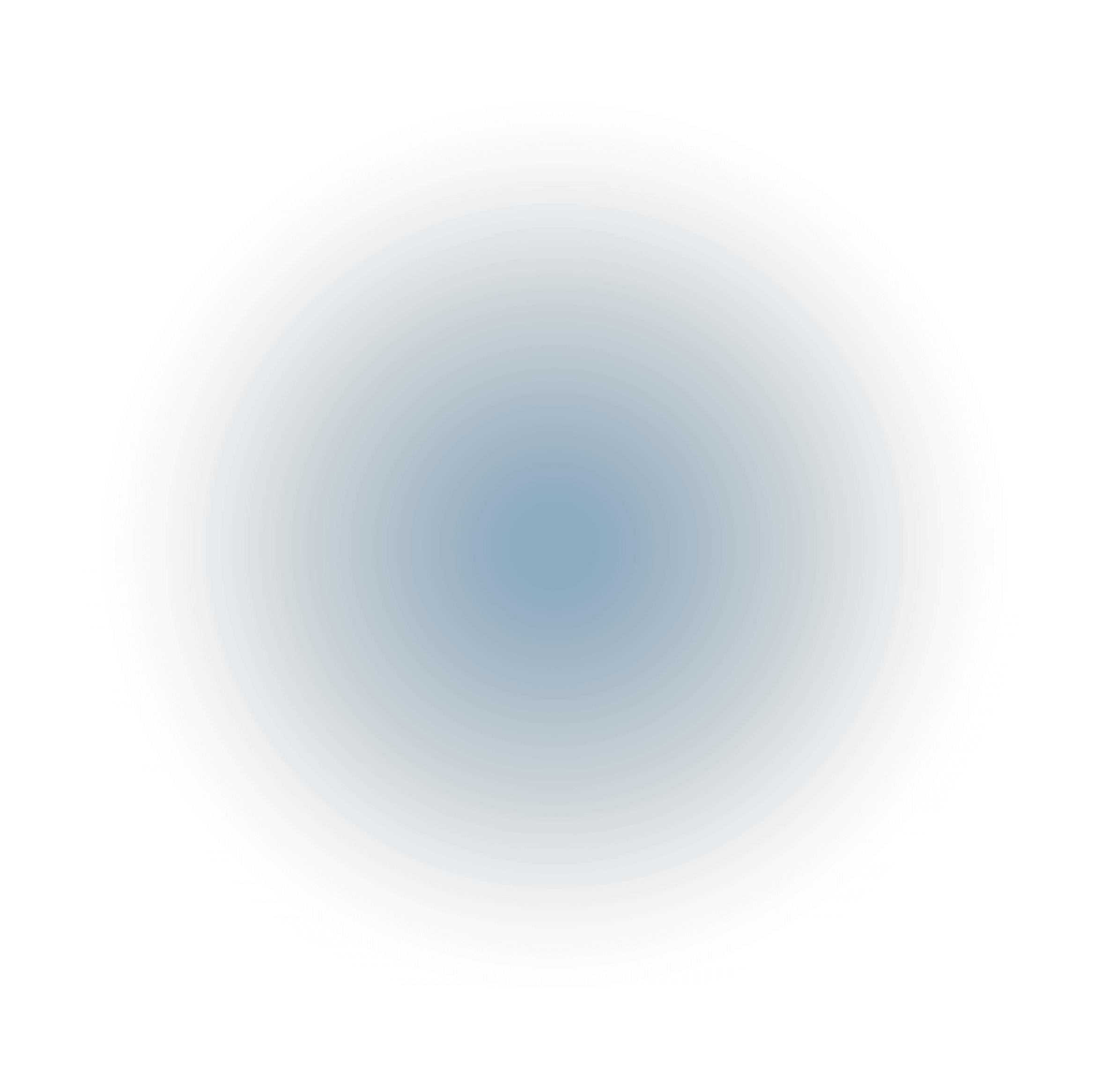

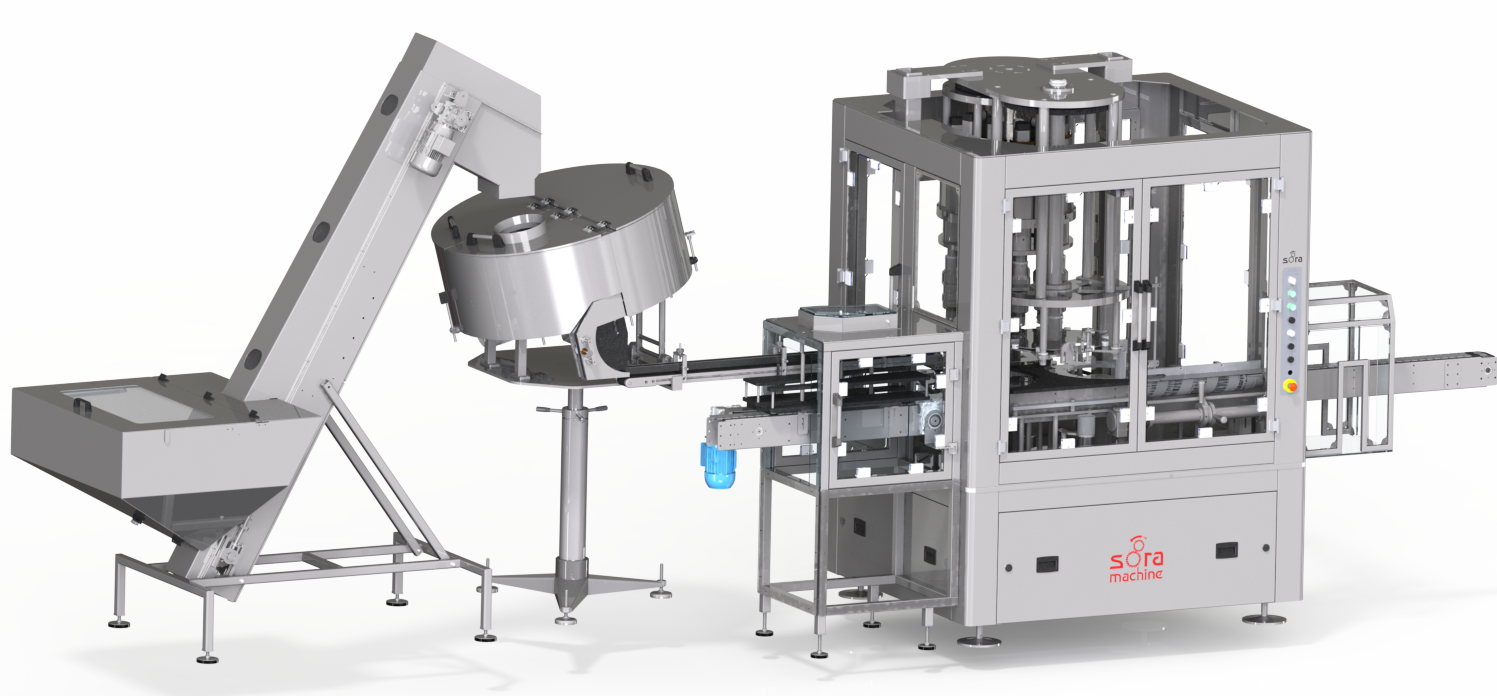

What is a Bottle Unscrambler System and Why is It Important in Production Lines?

A Bottle Unscrambler, or bottle straightening system, consists of specialized machines that automatically sort, orient, and transfer plastic bottles from bulk form into an upright position onto the production line. These systems are positioned at the beginning of automatic liquid filling lines and ensure a seamless flow throughout the entire line.

The Bottle Unscrambler unit developed by Sora Machine is optimized for high-capacity and hygienic production environments. This system minimizes human intervention on the production line while ensuring accurate bottle orientation and efficient operation.

How Does a Bottle Unscrambler Work?

The Sora Machine Bottle Unscrambler operates through the following steps:

- Bulk Bottle Feeding: The operator pours the bottles into the hopper.

- Disc Sorting Mechanism: A rotary table system separates the bottles one by one.

- Orientation Unit: Bottles are set upright and guided onto the line.

- Recycling: Incorrectly positioned bottles are automatically sent back to the system for re-processing.

- Transfer to Conveyor: Bottles are transferred in the correct position to the filling unit.

This entirely automatic process eliminates time loss and manual errors during production.

How Do Bottle Unscrambler Systems Increase Production Performance?

An automatic bottle orientation system is the most critical step before filling. Here are the advantages you’ll gain with Sora Machine’s Bottle Unscrambler solution:

- Reduced labor: No need for manual bottle placement.

- Continuous production flow: Prevents bottle jams or pile-ups.

- Minimized line stoppages: A smooth bottle flow increases the efficiency of the entire line.

- Prevents packaging damage: Bottles are conveyed in an upright and correct position.

- Easy cleaning and maintenance: Hygienic design allows for quick cleaning.

These benefits offer a sustainable and economic production advantage, especially for brands with high-volume production.

Why Should You Choose the Sora Machine Bottle Unscrambler?

Sora Machine is an engineering brand known for its high-quality automation solutions. The Bottle Unscrambler solution has been developed with this philosophy in mind:

- Compact design for easy installation in limited spaces.

- High speed and precision ensure stable production.

- Long-lasting components lead to low maintenance costs.

- User-friendly interface for easy operation.

- Local and international support services.

This product is not just a part of your production line; it’s a center of efficiency.

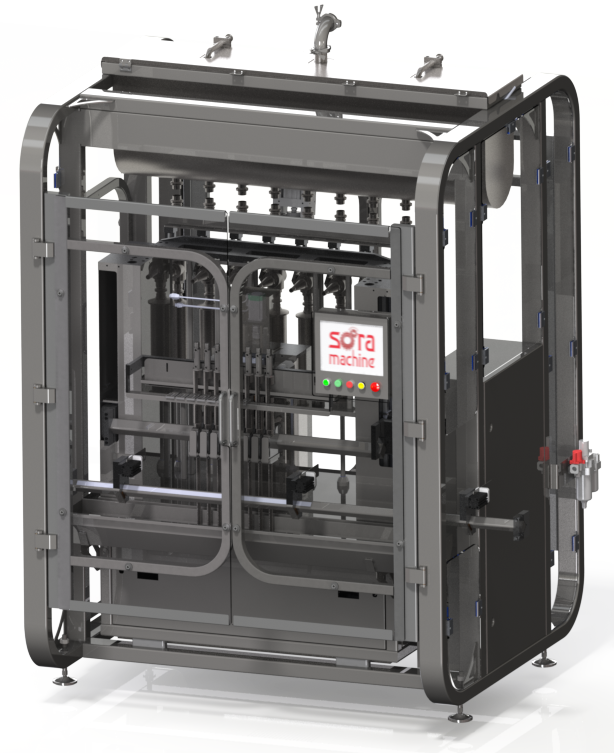

LIQUID FILLING MACHINE

- Suitable for different bottle types

- CIP Cleaning System

- Infeed/Outfeed Conveyor Queue Sensors

- SMC, FESTO ussed for pneumatic instruments

- ALLEN BRANDLEY, SIEMENS, OMRON or similar brands for PLC control

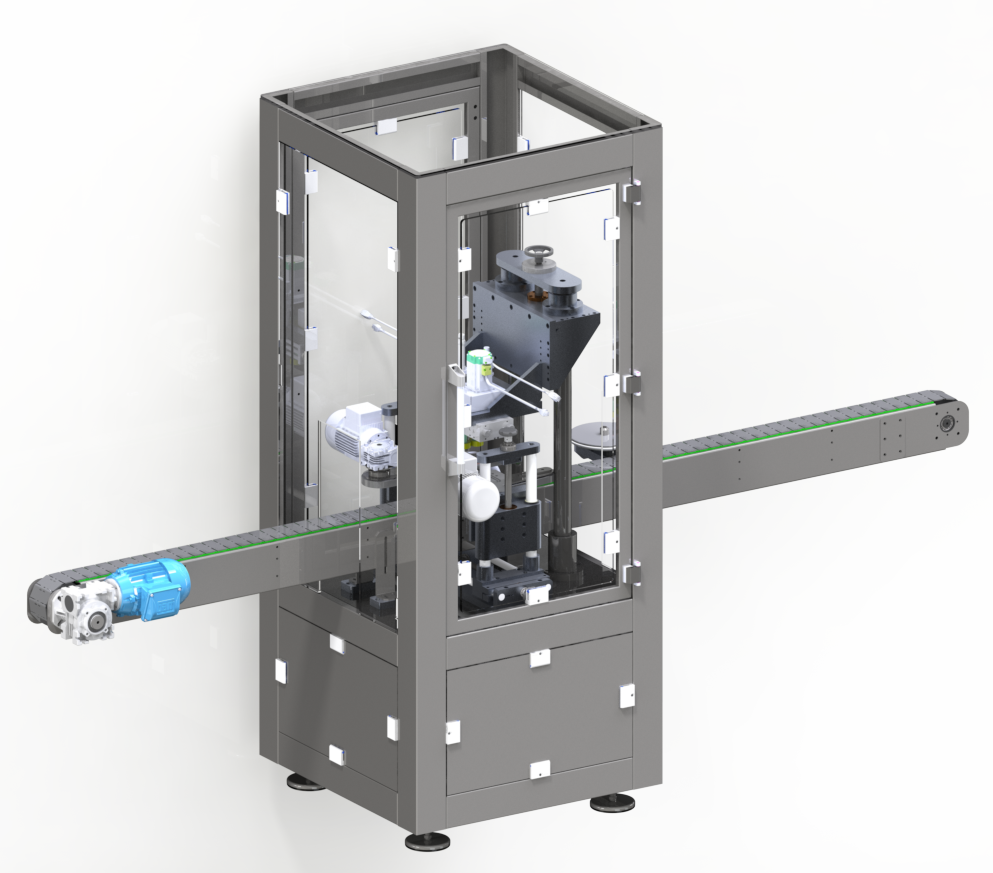

What is a Pump Sorting and Fitting Machine and What Does It Do?

A Pump Sorting and Fitting Machine is an automated system designed to automatically sort, orient, and assemble pump caps onto bottles in liquid filling lines. It optimizes production processes, especially in the cosmetics, personal care, pharmaceutical, and cleaning product industries, by performing pump placement with high speed and precision.

In Which Production Lines Is This Machine Used?

Pump sorting and fitting machines are an essential part of automatic liquid filling lines. They are typically used in the following lines:

- Filling lines for personal care products like shampoo, soap, and lotion.

- Cosmetic product lines such as perfume, cologne, and body mist.

- Chemical product lines for items like disinfectants and surface cleaners.

- Liquid product packaging lines in the food industry (e.g., sauces, liquid sweeteners).

These systems are compatible with both plastic and metal pumps, offering flexible and modular production capabilities.

How Does an Automatic Pump Sorting System Work?

The pump fitting machine developed by Sora Machine operates as follows:

- Pump Feeding Unit: Bulk pumps are organized by a vibratory system.

- Pump Sorting Mechanism: Pump nozzles and tubes are sorted by proper orientation.

- Positioning and Transfer: Properly sorted pumps are transferred to conveyor belts.

- Pump Placement Head: The pump is placed onto the bottle, with its accuracy checked.

- Torque-Controlled Tightening (optional): If the pump is screw-on, a torque-controlled tightening unit is activated.

This system can be customized for both dispenser pumps and spray pumps.

How Does the Machine Increase Production Efficiency?

The advantages offered by this automatic pump fitting system include:

- Minimizing human error.

- Reducing processing time per bottle.

- Ensuring more consistent and aligned placement.

- Lowering waste rates through operational speed.

- Decreasing labor costs in the long run.

Thanks to automation, production line downtime is avoided, and the Return on Investment (ROI) period is shortened.

With Which Other Systems Can This Machine Integrate?

The Pump Sorting and Fitting Machine can seamlessly integrate with Sora Machine’s LIQ MAK Up to 60 BPM liquid filling line. This creates a fully automatic line, ensuring uninterrupted and error-free production.

Why is Sora Machine Preferred in This Field?

Sora Machine is not just a machine manufacturer; it’s also a system partner that provides turnkey solutions to manufacturers. The key advantages it offers with this product include:

- Flexible production: Quick transition between different pump types.

- Compact design: Saves space.

- Fast maintenance and cleaning: Contact surfaces can be easily sterilized.

- Remote support systems: Error diagnosis and solutions via PLC.

Furthermore, Sora’s service and technical support team assists users with post-installation training and maintenance processes.

What is a Pump Tightening and in Which Production Processes is It Used?

A Pump Tightening is an automatic capping station specifically designed to securely screw on pump caps in liquid filling lines. For pump bottles containing liquid soap, shampoo, disinfectants, cleaning products, and similar items, it’s crucial not only to place the cap but also to tighten it with a specific torque. Therefore, this unit was developed to ensure consistency, safety, and efficiency in the production line.

What Types of Caps Are Compatible with This System?

Sora Machine’s Pump Tightening unit is compatible with the following cap types:

- Pump caps

- Trigger spray caps

- Disc top or flip top caps (compatible versions)

- Screw-type liquid dosing pumps

The machine can be customized to accommodate different sized caps, as it’s equipped with adjustable mechanical and pneumatic systems based on the cap’s geometry. Its flexible design allows for working with various packaging types on a single line.

How Does the Pump Tightening Unit Increase Production Efficiency?

Manual tightening processes can lead to both time loss and inconsistent product quality due to uneven torque. The Pump Tightening unit helps achieve:

- Guaranteed sealing by applying equal torque to every bottle.

- Reduced operator intervention and improved ergonomics.

- Optimized overall production speed by shortening the tightening time.

Additionally, because the error rate is minimized, there is a lower rejection rate during the final product quality control stage.

What is Its Technical Structure and Ease of Integration?

Sora Machine’s unit features a modular design, making it easy to integrate into existing filling lines. Some of its technical features include:

- Automatic or semi-automatic torque adjustment

- High-precision tightening heads

- Pneumatic or servo motor-assisted system

- Structure suitable for continuous pass-through production on a conveyor

All these features ensure uninterrupted production by performing the tightening operation without stopping the line.

Which Industries Should Prefer This System?

The Pump Tightening unit can be used in almost any industry that produces liquid, semi-liquid, or viscous products:

- Cosmetics industry: Shampoo, conditioner, lotion, hand soap

- Medical products: Disinfectants, antiseptics

- Household cleaning products: Surface cleaners, liquid detergents

- Food industry: Syrups, sauces, liquid supplements (in pump packaging)

Thanks to its wide range of applications, this system is suitable for both small-scale manufacturers and high-capacity facilities.

How to Get the Highest Performance from the Tightening Unit?

To increase efficiency, it’s recommended to pay attention to the following details:

- The tightening torque should be correctly calibrated according to the cap and product type used.

- It should be ensured to work in coordination with the cap placement unit on the line.

- Cleaning and maintenance periods for the tightening heads should be performed regularly during operation.

These measures will increase the system’s performance and minimize the breakdown rate.

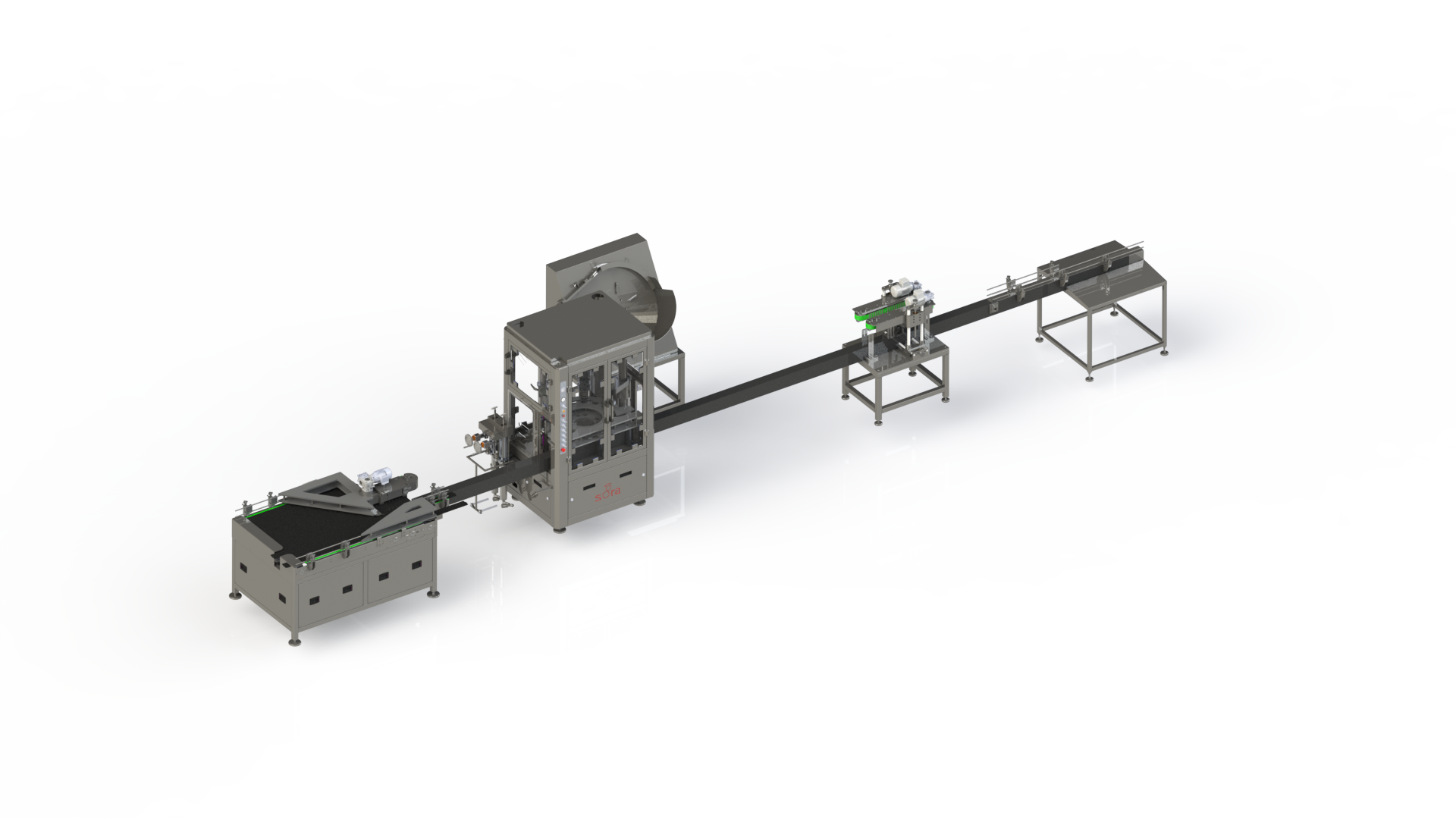

What is the LIQ MAK Up to 60 BPM?

Sora Machine’s LIQ MAK Up to 60 BPM model is an automatic liquid filling machine engineered for high-speed and precise filling of liquid products. Reaching a maximum speed of 60 bottles per minute (BPM) on production lines, this system offers hygienic filling, repeatability, and a low defect rate. It’s particularly favored for liquid formulations in cosmetics, personal care, pharmaceuticals, and cleaning products.

Which Product Types is It Suitable For?

LIQ MAK is adaptable for filling a wide range of products with varying viscosities. It’s commonly used for:

- Toners and lotions

- Makeup removers

- Alcohol-based products like cologne and perfume

- Personal care items such as liquid soap, shampoo, and shower gel

- Medical antiseptics and disinfectants

- Household cleaning solutions

Its adaptability to different mouth diameters, cap types, and bottle shapes allows for the production of multiple product variations on a single line.

What Filling Technology Does This Machine Utilize?

The Sora Machine LIQ MAK model employs precise volumetric filling technology. This ensures that the same amount of product is filled into each bottle at a consistent speed and pressure. Key technological features of the filling system include:

- Adjustable filling volume

- Drip-free nozzles

- Top-to-bottom filling option to prevent foaming

- Anti-drip mechanism

These features prevent waste during filling, reduce cleaning needs, and enhance hygiene standards.

What Does “60 Bottles Per Minute” Really Mean?

A speed of 60 BPM (Bottles Per Minute) signifies an optimal level of productivity, especially for medium to large-scale production lines. This capacity:

- Helps meet high demand during promotional periods.

- Reduces production time, thereby lowering labor costs.

- Optimizes production costs by decreasing waste.

In essence, when integrated with proper bottle feeding and collection systems, it forms the core of a fully automated and highly efficient filling line.

How Does a Sleeve Dropping Machine Play a Role in This Process?

A Sleeve Dropping Machine, which can be integrated into the LIQ MAK line, automatically applies shrink sleeves (heat-shrinkable labels) to product packaging after bottle filling. This system:

- Precisely places transparent or pre-printed sleeves onto bottles.

- Eliminates alignment errors common with manual application.

- Works seamlessly at high speeds, without disrupting production flow.

- Integrates with systems like a shrink tunnel to ensure the label perfectly conforms to the product.

The Sleeve Dropping Machine is a critical component for enhancing visual integrity and brand perception, particularly in the cosmetics and personal care sectors.

What Technical Features Make This Machine Stand Out?

The outstanding technical features of LIQ MAK include:

- 60 BPM production capacity

- Stainless steel body and GMP-compliant design

- Compatibility with automatic bottle feeding options

- Control via a PLC control panel and touchscreen display

- Modular structure allowing for quick format changes

- Integration infrastructure for capping and sleeve labeling systems

This design allows it to operate seamlessly in both fixed and modular production environments.

Which Sora Machine Units Can It Be Integrated With?

LIQ MAK can be integrated with other Sora Machine automation solutions to maximize production efficiency, including:

- Rotary Feeding Table: Ensures bottles are correctly fed into the machine.

- Rotary Collecting Table: Helps organize products emerging from the filling process.

- Monoblock Feeding Station: Can be used as a system that feeds the entire integrated process.

- Sleeve Dropping Machine: Ensures visual quality and product integrity during the labeling process.

What is the Level of Compliance with Hygiene Standards?

All surfaces of LIQ MAK are manufactured from AISI 304/316 quality stainless steel, designed in compliance with GMP and HACCP requirements. Additionally, it features:

- Easily accessible covers and nozzles for cleaning.

- Leak-proof sealing systems at liquid transfer points.

- A washable, sterilization-compatible structure.

This design enables the safe execution of processes involving hygiene risks, particularly for medical and personal care products.

Why Should You Choose LIQ MAK?

Sora Machine’s LIQ MAK model stands out with its combination of high-precision filling, modular design, hygienic construction, and speed. Furthermore, it offers:

- Quick mold changes for flexible production.

- Long-term durability.

- Technical service and engineering support.

- 100% compatibility with other line solutions.

The Sora Machine difference is about providing not just a machine, but a complete production partnership.

What is a Labeling Machine and Why is it Important?

Labeling machines are critical equipment at the final stage of a liquid filling line, essential for clarifying product identity and ensuring brand consistency. Sora Machine’s LIQ-MAK UP TO 60 BPM stands out as an indispensable component of modern production lines, offering high speed, precision, and a flexible design.

What Product Types Is It Used For?

This labeling system is developed to work seamlessly with liquid filling machines and can be used for packaging products such as:

- Cosmetics like shampoo, body lotion, and hair conditioner

- Disinfectants, liquid soaps, and cleaning products

- Liquid sauces, oils, and beverages used in the food industry

- Pharmaceutical products and specially formulated liquid products

The machine is compatible with plastic and glass bottles of various diameters and heights.

What Features Make the LIQ-MAK 60 BPM Labeling Machine Stand Out?

1. High Capacity

This model boasts a labeling capacity of up to 60 bottles per minute. It integrates smoothly into fast-paced production processes, preventing bottlenecks.

2. Adjustable Structure

The machine is adjustable to accommodate different bottle diameters and label sizes. This flexibility allows for the management of a wide range of product groups through a single system.

3. PLC-Controlled Automation

The fully automatic control system is combined with a user-friendly touchscreen interface. Operators can easily manage parameters such as:

- Label length

- Application position

- Bottle counter

What Are the Technical Details?

| Feature | Description |

|---|---|

| Body Material | AISI 304 Stainless Steel |

| Labeling Type | Automatic, adhesive labeling |

| Capacity | Up to 60 bottles per minute |

| Compatible Bottle | Ø 30 – 100 mm |

| Label Accuracy | ± 1 mm |

| Electrical Components | Siemens, Omron, Schneider, SMC |

| Control Panel | PLC + Touch Screen |

How is it Positioned in the Production Line?

The labeling machine is integrated at the end of the filling line. When used in conjunction with the following systems, it ensures a complete production flow:

- Automatic Bottle Feeder

- Vacuum or piston filling machines

- Capping and tightening units

- Sleeve dropping machines

- Collecting table

This integration allows bottles to complete all stages, from filling to labeling, without interruption.

Does It Offer Operational Ease?

Yes. The system can be easily managed by a single operator. Features that enhance user experience include:

- Quick transitions during format changes

- Plug-and-play installation

- Tool-free mechanical adjustments

- Live monitoring via screen for fault detection and error alerts

What Is a Collecting Table and Why Is It Essential in Liquid Filling Lines?

A collecting table is the final station in a liquid filling line where finished products are accumulated after filling, capping, or labeling. Also known as an accumulation table, it serves as a buffer zone that collects filled bottles or containers, allowing operators to package them without interrupting the flow of the production line.

In systems with up to 60 BPM (bottles per minute) capacity, a collecting table prevents line congestion, supports smoother workflow, and enhances overall production efficiency—especially in semi-automated or operator-assisted environments.

How Does a Collecting Table Work?

A collecting table operates through a rotating or fixed flat surface positioned at the end of the production conveyor. As filled bottles exit the line:

-

Products arrive on the conveyor belt

-

They are gently guided onto the collecting table surface

-

Operators manually remove or pack the bottles as they accumulate

The rotating models ensure even distribution of products on the table surface. Collecting tables typically work without active sensors or motors, making them mechanically simple but operationally crucial.

What Are the Benefits of Using a Collecting Table in Semi-Automated Filling Systems?

In production environments such as Liq-mak up to 60 bpm, the collection of tables offers significant operational advantages::

-

Improved efficiency: Operators can handle packaging in parallel without slowing down the line

-

Reduced bottlenecks: Prevents line stoppages due to full conveyors

-

Labor optimization: Operators focus on packing instead of chasing bottles on the line

-

Smooth product flow: Ideal for lines with intermittent downstream activity

-

Flexible use: Can be used in various industries like cosmetics, pharmaceuticals, or food

Especially in compact production setups, collecting tables increase flexibility without requiring advanced automation.

Where Is a Collecting Table Typically Placed in a Liquid Filling Line?

The collecting table is positioned at the end of the conveyor line, directly following the last machine in the process (usually the capping or labeling unit). Its primary function is to:

-

Gather finished products before secondary packaging

-

Offer buffer time to downstream operators

-

Allow for inspection or batch sorting if necessary

It can also be placed between stages as a temporary holding area, especially when one part of the system is faster than the next.

What Are the Key Features of Sora Machine’s Collecting Tables?

Sora Machine’s collecting tables are designed for durability, hygiene, and ergonomic use. Key technical specifications and features include:

-

Stainless steel construction for easy cleaning and corrosion resistance

-

Height-adjustable legs for seamless integration with different line heights

-

Polished flat or rotating tabletop (optional) for smooth bottle movement

-

Safety edges and non-slip feet for secure operation

-

Customizable dimensions based on container size and line layout

These tables are manufactured to suit a wide range of packaging formats, including PET, glass, and plastic bottles in various shapes and volumes.

In Which Industries Are Collecting Tables Commonly Used?

Collecting tables are standard equipment across multiple low-to-medium speed filling applications. Most common sectors include:

-

Cosmetics – Liquid foundation, toner, micellar water, serums

-

Pharmaceuticals – Syrups, oral solutions, tinctures

-

Personal Care – Shampoos, lotions, body wash

-

Household Chemicals – Cleaning liquids, surface sprays

-

Food & Beverage – Condiments, sauces, flavored syrups

Any product that is packaged in bottles or containers and requires operator handling at the end of the line can benefit from a collecting table.

What Should You Consider When Choosing a Collecting Table?

Before selecting a collecting table, manufacturers should evaluate several factors:

-

Line speed: Is the BPM compatible with the table size and surface area?

-

Container type and stability: Will the bottles remain upright and balanced?

-

Available floor space: Can the table fit at the end of the line without obstructing flow?

-

Operator access: Is the layout ergonomic for packing and quality checks?

-

Surface type: Do you need a rotating disk or a flat accumulation zone?

Sora Machine helps clients choose or customize the ideal collecting table for their specific line configuration.

Can a Collecting Table Be Upgraded or Automated?

Yes, collecting tables can be upgraded with additional features or adapted for higher efficiency. Some possible enhancements include:

-

Rotating turntables to keep product flow continuous

-

Sensor-based accumulation control to prevent overflow

-

Integration with downstream packing equipment

-

Mobility wheels or locking casters for repositioning

-

Adjustable guides for multi-format bottles

While the base version is manual and mechanical, semi-automation is possible with minimal investment.

What is a Mascara Filling Machine and How Does Sora Machine Offer Solutions for This Process?

Mascara filling machines are systems developed to perform the filling of mascara automatically and hygienically, making it one of the most delicate production processes in the cosmetics industry. Sora Machine’s mascara filling solution, offering a capacity of up to 40 fills per minute, is optimized to work seamlessly even with high-viscosity formulas.

For cosmetic products with special consistencies like mascara, filling accuracy, formula preservation, and production speed must be managed simultaneously. At this point, Sora Machine, with its high-precision volumetric filling technology, enables manufacturers to achieve fast and stable production that meets their quality standards.

Which Production Volume is a 40 BPM Mascara Filling Machine Suitable For?

This model, offering performance of up to 40 fills per minute, is ideal for medium to high-scale cosmetic manufacturers. The system provides sufficient production tempo for brands targeting thousands of products daily, shortening filling times while also helping to reduce labor costs.

Its design, suitable for high-viscosity formulas (e.g., fiber-infused, highly volumizing, or waterproof mascaras), is a significant factor that makes this machine stand out in the market.

What Features Does the Sora Machine Mascara Filling Solution Come Equipped With?

This machine is not just a filling system, but an integrated production solution. It comes standard with the following equipment:

- Servo-controlled volumetric filling unit

- Brush and cap feeding conveyor

- Capping device

- Bottle discharge unit

- 30L stainless steel pressure tank

- Mitsubishi brand touchscreen control panel

The user-friendly design of this system ensures that the production process is easy, flexible, and safe for operators.

What Advantages Does a Monoblock Filling Station Provide in Mascara Production?

Sora Machine’s monoblock mascara filling station is integrated to perform filling, brush insertion, and capping operations on a single platform. This design saves space while minimizing operator intervention and reducing errors.

The monoblock system:

- Optimizes production time.

- Meets GMP standards thanks to stainless steel in contact areas.

- Allows for easy format changes for different packaging types.

For brands that want to offer high speed and quality simultaneously, this system is a solution that will be at the heart of their production.

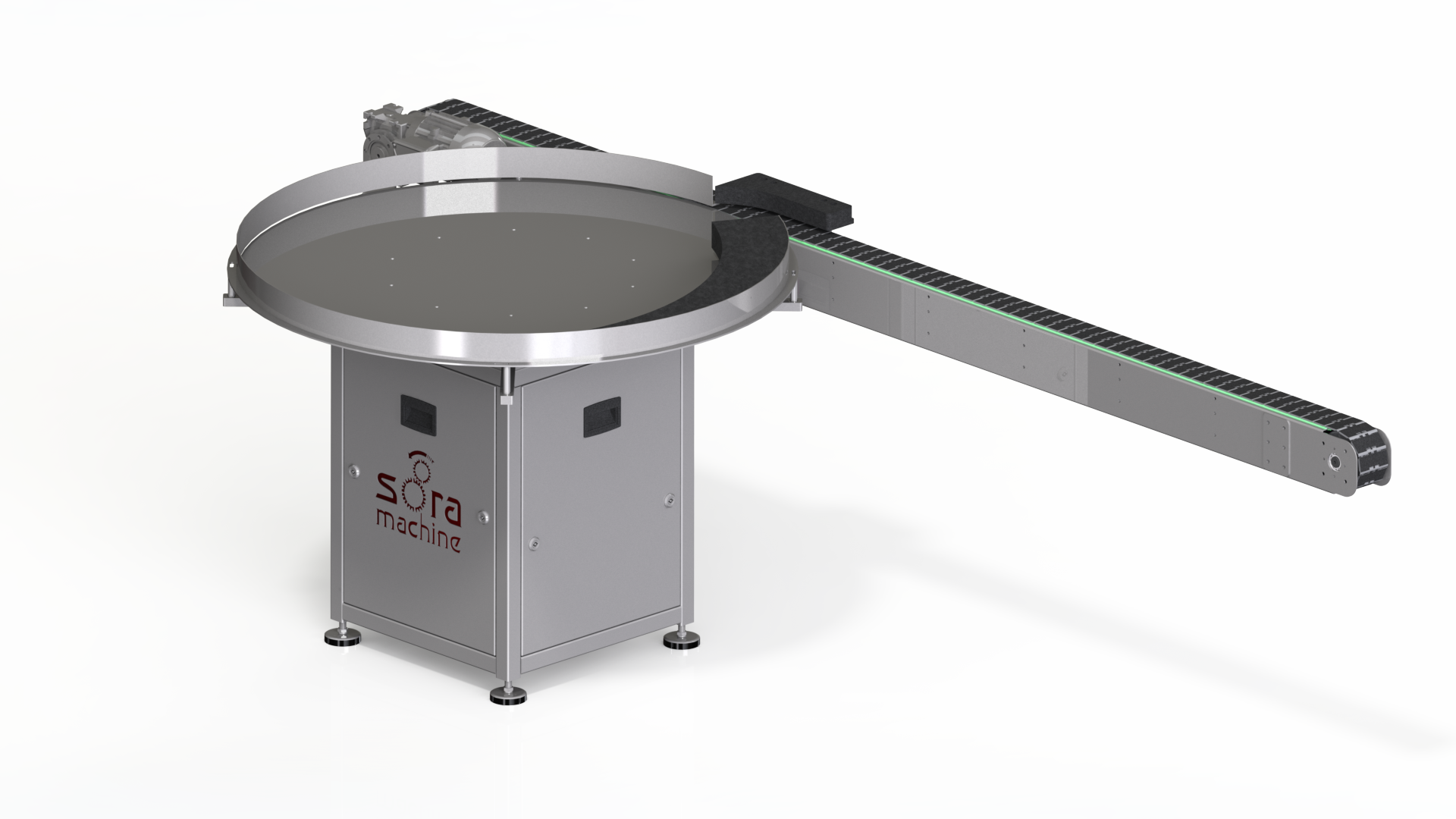

What is a Rotary Feeding Table and Why is it Used?

To ensure proper flow and timing in production lines, bottles entering the filling machine must be fed regularly. At this point, a rotary feeding table offers a practical solution where operators can randomly place bottles, but the system aligns them and directs them to the production line.

Sora Machine’s rotary feeding table:

- Is compatible with round bottles.

- Can be adapted to different production lines due to adjustable height.

- Offers low maintenance with gearbox drive.

- Is suitable for hygienic production environments with its stainless steel surface.

This table is critical for ensuring a continuous and stable feed at the starting point of your production line.

How Does a Rotary Collecting Table Support the Production Process?

Once filling and capping operations are complete, products need to be collected regularly and directed to subsequent steps (labeling, packaging, etc.). A rotary collecting table provides an ergonomic and organized exit that operators can easily access.

Sora Machine’s rotative collecting table:

- Ensures bottles are collected together without tipping.

- Offers installation flexibility with its reversible feature.

- Provides long life and low maintenance by using a gearbox instead of chains or belts.

- Is easy to clean and GMP compliant due to its stainless steel construction.

This equipment at the end of the production line is a system that completes the process and maintains flow without losing speed.

How Do All These Systems Work Together Harmoniously?

Sora Machine’s production philosophy is to offer not just a single machine, but integrated, modular, and flexible line solutions. The mascara filling machine ensures a continuous product flow with the rotary feeding table, while enabling quick and neat product retrieval at the end of production thanks to the rotary collecting table. The monoblock station, at the heart of production, carries out filling and capping operations in an integrated manner.

These systems:

- Reduce time loss.

- Minimize human intervention.

- Standardize product quality.

- Lower operational costs.

What is the Lipgloss Filling Up to 40 BPM Machine?

Developed by Sora Machine, the Lipgloss Filling Up to 40 BPM is a specialized make up filling machines designed to safely, hygienically, and precisely fill highly viscous cosmetic products. With a production capacity of up to 40 units per minute, it offers an ideal solution for medium-scale production lines. This system is particularly optimized to accommodate the viscous nature of lipgloss formulations.

Which Cosmetic Products Is It Suitable For?

This machine is primarily suitable for lipgloss and similar semi-liquid formulations of comparable density. Example products include:

- Glossy lip products

- Lightly pigmented liquid lipsticks

- Lip care serums

- Low-volume, high-viscosity serums

It provides high repeatability and precision for these types of products, which are often challenging to fill with standard systems.

What Technologies Does It Utilize?

The lipgloss filling machine is equipped with Sora Machine’s advanced technologies. Its core features include:

- Piston filling system (adjustable according to viscosity)

- No-drip nozzles (prevents product dripping)

- Vacuum scraping system

- PLC-controlled touchscreen panel

- Stainless steel body and food-contact compliant parts

- Filling tolerance with ±1% accuracy

These features enable both high-quality production and compliance with GMP standards.

How Does It Integrate with Monoblock Lipgloss Filling Station?

This filling system is designed to work in full integration with Sora Machine’s Monoblock Lipgloss Filling Station. The station’s contributions include:

- Servo motor-controlled filling volume and speed adjustment

- Pneumatic cylinder for nozzle up-and-down movement

- “No bottle, no fill” principle to prevent waste

- Easy-to-clean modular design

- Design suitable for automatic format change

Thanks to the monoblock structure, processes like product feeding, filling, and cap placement are performed smoothly from a single station.

Is It Easy for Operators to Use?

Yes, this machine features a user-friendly PLC screen interface. Operators can:

- Adjust filling quantity, flow rate, and timing

- Quickly switch between different product types

- Instantly monitor fault or warning systems

- Complete cleaning and maintenance procedures in a short time

This significantly reduces training time and increases efficiency on the production line.

Does It Comply with Hygiene and Cleaning Standards?

Hygiene is a top priority in the machine’s design. In compliance with GMP (Good Manufacturing Practices):

- All product-contact surfaces are made from stainless steel.

- It can be integrated with an automatic cleaning-in-place (CIP) system.

- Pistons and nozzles can be easily dismantled and sterilized.

- The vacuum system minimizes product leaks.

This design ensures both product safety and streamlines the cleaning process.

How Is Filling Quality and Consistency Ensured?

The machine’s piston system automatically adjusts to product consistency and operates with ±1% accuracy for each fill. Additionally:

- Back-suction nozzles provide extra protection against dripping.

- A vacuum-assisted scraper prevents residue on the nozzle rim.

- A controlled flow system prevents foaming.

This ensures consistent quality with every fill.

Which Auxiliary Systems Can It Be Integrated With?

The machine can be configured to integrate into a fully automatic production line. Compatible systems include:

- Monoblock Lipgloss Filling Station: Combines product feeding, filling, and cap placement on a single platform.

By integrating these systems, every stage of the production line is automated, saving labor and time.

What Does Technical Service and Support Cover?

Sora Machine offers comprehensive support for this model, as with all its systems:

- On-site installation and commissioning services

- Operator training

- Remote technical support

- Spare parts supply and maintenance planning

Furthermore, customized engineering solutions for production needs are also part of Sora Machine’s services.

What Do Nail Polish Filling Machines Do?

Nail polish filling machines automatically, precisely, and hygienically bottle high-viscosity cosmetic products such as nail polish, top coats, and similar items. These machines are specifically developed for filling operations into small-volume glass or plastic packaging. Sora Machine’s solution in this area is a high-precision automation system capable of operating at production speeds of up to 40 BPM (bottles per minute).

Which Products Are Compatible with the Sora Machine Nail Polish Filling Unit?

This system works with high efficiency, especially for the following product types:

- Classic nail polish formulas

- Gel-based nail polishes

- Clear and colored protective nail products

- Nail hardener formulations

- Glitter or particle-infused polishes

To enable smooth filling of these varying viscosity products, the machine is equipped with piston or peristaltic pump options.

Which Packaging Formats Does This System Support?

Sora Machine’s nail polish filling machine, operating at up to 40 BPM, is compatible with the following packaging types:

- Glass bottles with volumes of 5 ml, 10 ml, and 15 ml

- Small-volume plastic packaging with narrow necks

- Bottles with integrated or subsequently placed brush caps

Regardless of the packaging shape, the system has a flexible structure that can be adjusted according to bottle height and cap type.

What Are the Stages of the Filling Process?

Sora Machine’s filling machines in this segment have the following operational steps:

- Bottle feeding: Bottles are fed into the system manually or via a rotary feeder.

- Precise filling: The nail polish formula is transferred into the bottle with adjustable dosage.

- Brush and cap placement: Caps with integrated brushes are positioned automatically.

- Cap tightening: Caps are secured using a torque-controlled tightening mechanism.

- Output and collection: Bottles are conveyed forward to the next process.

Why Should Nail Polish Manufacturers Prefer This System?

Consistency, visual quality, and minimum waste rates are among the most critical issues in the production of nail polish and similar cosmetic products. The advantages offered by Sora Machine’s system include:

- Grammage deviations are prevented thanks to high-precision filling.

- Air bubble formation is minimized, preserving product aesthetics.

- Error-free capping is ensured with automatic brush placement.

- Space-saving due to its compact design.

- Short changeover times offer quick transitions between different bottle and formulation types.

Why is Sora Machine a Reliable Partner in This Field?

Sora Machine is an engineering brand known for its experience in makeup filling lines and application engineering, creating customized solutions for each client. It aims to meet all manufacturers’ needs with its product quality, technical support strength, and international service capacity.

- Over 20 years of experience

- R&D-backed engineering solutions

- European standard production quality

- Advanced automation options

- Global after-sales support network

How Does the Purchasing and Technical Support Process Work?

Sora Machine not only provides machines to its customers but also offers project consultancy and post-installation training support. You can contact them directly to get a quote for a nail polish filling machine, receive support for customized configurations for your production line, or obtain technical information.

What is a Rotary Perfume Filling Machine and For Which Productions Is It Preferred?

A rotary (rotary type) perfume filling machine is a multi-station automatic system specifically designed for medium and high-volume production lines. It ensures high-speed, precise, and consistent filling of perfumes and similar low-viscosity liquids into bottles. It offers a homogeneous, error-free, and efficient filling process for both aesthetically packaged products and industrial-scale productions.

How Does the Rotary System Differ from Other Filling Systems?

Sora Machine’s rotary filling line stands out due to the following advantages:

- Continuous motion system: Production flows uninterrupted, with filling continuing without pauses.

- Multi-station structure: Steps like filling, cap placement, and capping can occur simultaneously.

- Higher BPM (Bottles Per Minute): Provides greater bottle processing capacity per minute.

- Fully automatic structure: Minimizes human intervention, increasing production continuity.

This structure maximizes efficiency in mass production-oriented cosmetic facilities, going beyond classic linear systems.

Which Products Is It Suitable For?

The rotary system is ideal for the following product groups:

- Perfumes (alcohol-based and alcohol-free)

- Room fragrances

- Colognes

- Body sprays

- After-shave and aromatic liquids

The system can be configured to suit glass, plastic, or metal bottles.

What Functions Do Other Integrated Units Provide to the System?

The rotary perfume filling system can be integrated into Sora Machine’s monoblock perfume lines or modular automation systems. It is typically used in conjunction with the following units:

- Rotary feeding unit (bottle sorter)

- Vacuum filling module

- Crimping – valve sealing unit

- Sprayer (spray pump) placement

- Labeling machine

- Coding and batch marking system

All these modules work in full synchronization. They can be added or configured as needed.

Which Sectors Prefer It?

Rotary perfume filling machines are widely used in the following sectors:

- Cosmetics

- Personal care products

- Perfumery

- Hotel/SPA product filling facilities

- Private label manufacturers

High-volume production facilities prefer rotary systems for serial filling and packaging.

Does It Provide Time and Cost Advantages in Production Processes?

Yes, absolutely. Thanks to the rotary system’s continuous motion mechanism, the following benefits are achieved:

- Time savings: Multiple operations are completed in each cycle.

- Operational efficiency: Labor requirements decrease, and waste rates are reduced.

- Energy efficiency: High-volume production in a short time.

- Rapid depreciation: The return on investment period is shortened.

All these advantages allow businesses to increase their production capacity while keeping costs under control.

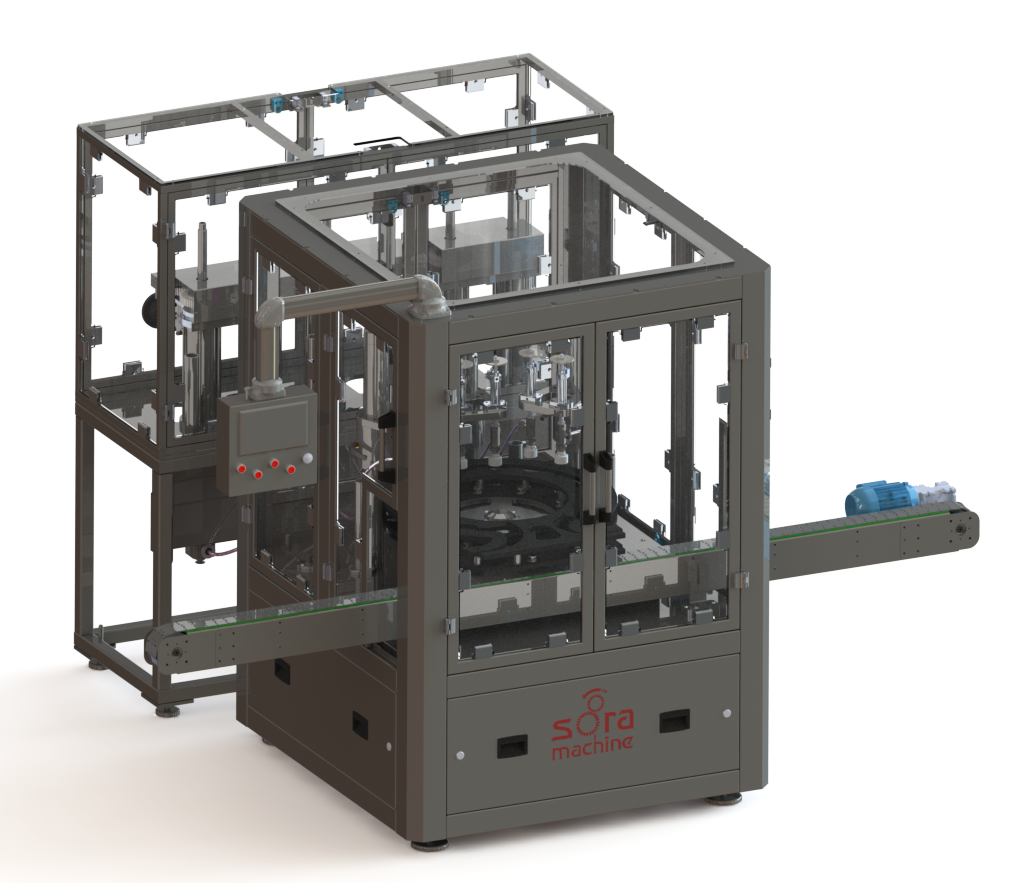

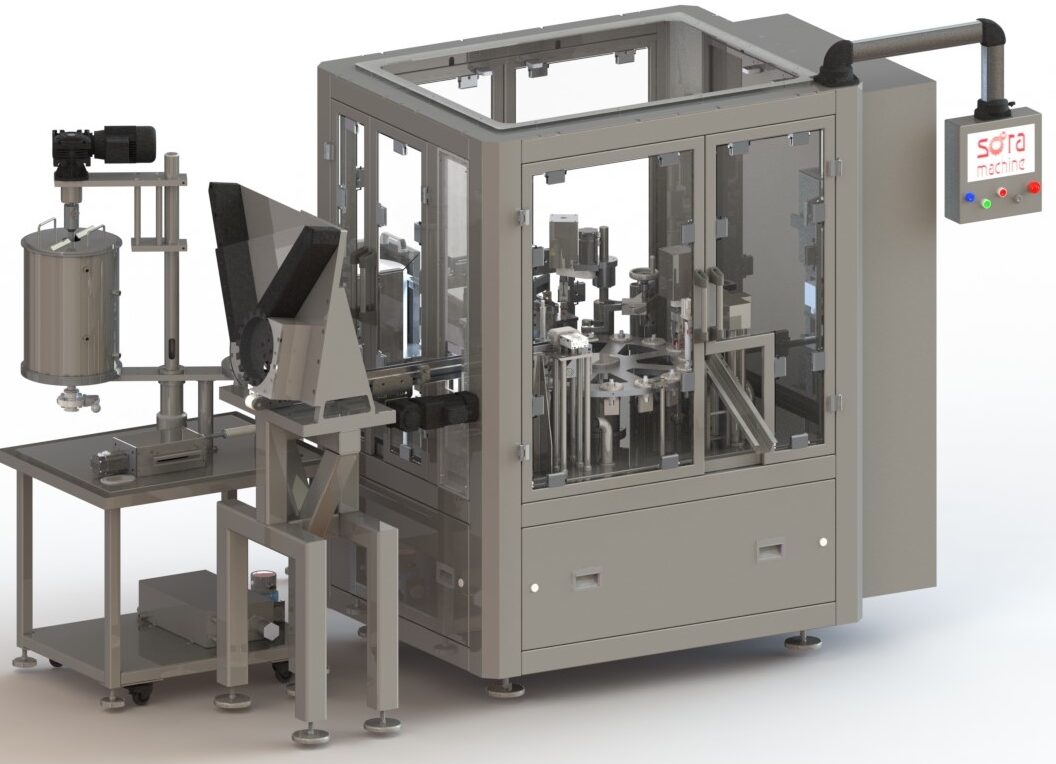

What is the Monoblock Perfume Filling Machine?

Sora Machine’s Monoblock Perfume Filling Machine is a fully automatic system that combines the filling, valve insertion, and capping processes for perfumes and similar liquid cosmetic products into a single, compact unit. This integrated design saves valuable production line space while delivering high efficiency and adhering to stringent hygiene standards.

What Product Types Is It Compatible With?

The Monoblock system is particularly suitable for the production of the following liquid products:

- Alcohol-based perfumes

- Colognes

- Low-viscosity liquids like body sprays

- Aroma and essential oil-based cosmetic solutions

All product-contact surfaces are made from stainless steel, ensuring compliance with hygiene criteria in the cosmetics and personal care sectors.

What Makes This System Different?

This model distinguishes itself from other perfume filling machines through its key features:

- Integrated Valve and Cap Placement: Valve and cap application are performed automatically after filling, ensuring an uninterrupted production process.

- Precise Vacuum Filling Technology: Fills products without foaming, preventing waste, and achieving an accuracy of ±1%.

- Compact Design: All process steps are housed within a single body, minimizing operator requirements and floor space.

What Are Its Technical Specifications?

Manufactured to Sora Machine’s high technical standards, this machine is equipped with the following specifications:

- Filling System: Vacuum-based

- Capacity: Up to 30 bottles per minute

- Material: AISI 304 and 316 stainless steel

- Electrical and Pneumatic Components: Global brands like SIEMENS, OMRON, SMC, FESTO

- Bottle Compatibility: Adaptable to bottles of various diameters and heights

- Control Unit: PLC-based digital interface (touchscreen)

- Safety Systems: Emergency stop options with a clutching mechanism and bottle detection sensors

Does It Offer Ease of Operation?

Yes, Monoblock Perfume Filling Machine with Valve & Cap Placing systems are known for enabling high efficiency with minimal operator involvement:

- Format changes can be performed quickly.

- Operator training time is short; management is easily done via the screen.

- Compatible with CIP (clean-in-place) systems for maintenance and cleaning.

- Contact surfaces can be disassembled without tools, providing a hygiene advantage.

Which Manufacturers Is It Suitable For?

This machine is particularly suitable for:

- Perfume brands with medium to high-volume production.

- Specialized cosmetic workshops.

- Businesses aiming to produce under GMP and ISO standards.

DEPALLETIZER

- 304 L construction