Aerosol filling technologies are playing an increasingly significant role in the chemical, cosmetics, pharmaceutical, and food industries. Innovations that enhance production efficiency, protect the environment, and provide cutting-edge solutions are driving revolutionary changes in this field. So, what are the latest trends in aerosol filling technologies? What does the future hold? Let’s explore together!

What Innovations Do Automation and Robotic Systems Bring?

Thanks to automation and robotic systems in aerosol filling machines, the production process has become faster and more precise than ever before. AI-powered machines can optimize filling processes autonomously, minimizing error rates. Smart sensors continuously monitor products in real-time, ensuring that quality standards are always maintained at the highest level.

Additionally, robotic arms and fully automated filling lines reduce human intervention, lowering labor costs. The advancement of robotic technology makes production processes more flexible while allowing operators to take on more strategic and analytical roles.

What Are the Eco-Friendly and Sustainable Filling Solutions?

Protecting the environment is no longer an option—it’s a necessity! The aerosol filling industry is shifting towards eco-friendly alternatives to traditional propellants to reduce carbon footprints. Additionally, aerosol cans made from recyclable materials can be reused without harming nature. The green production approach not only benefits the environment but also enhances manufacturers’ reputations.

Recent research on water-based propellants and biodegradable formulations has accelerated the development of eco-friendly alternatives. Leading brands are investing in sustainable products, considering consumers’ growing environmental awareness.

How Are Smart Filling Technologies Transforming Production Processes?

Industry 4.0 and the Internet of Things (IoT) are equipping aerosol filling machines with smart technologies, providing manufacturers with significant advantages. These systems analyze every stage of the production process to create the most efficient working environment. With real-time data tracking, potential malfunctions are detected in advance, minimizing downtime. Faster, more reliable, and more cost-effective production is now possible!

Moreover, cloud-based production monitoring systems enable managers to track processes remotely and intervene instantly when needed. In the future, AI-powered software will further refine predictive maintenance, ensuring uninterrupted production.

What Are the New Materials Used in Aerosol Products?

Reducing plastic usage is now a primary goal for the industry. Therefore, biodegradable and recyclable materials are gaining prominence in aerosol cans. These materials not only support environmental sustainability but also extend product shelf life, providing consumers with a higher-quality experience.

Aluminum-based and recyclable plastic cans play a crucial role in achieving sustainability goals. These materials contribute to energy savings in the production process while also enhancing durability.

What Are the Latest Updates in Safety Standards and Regulations?

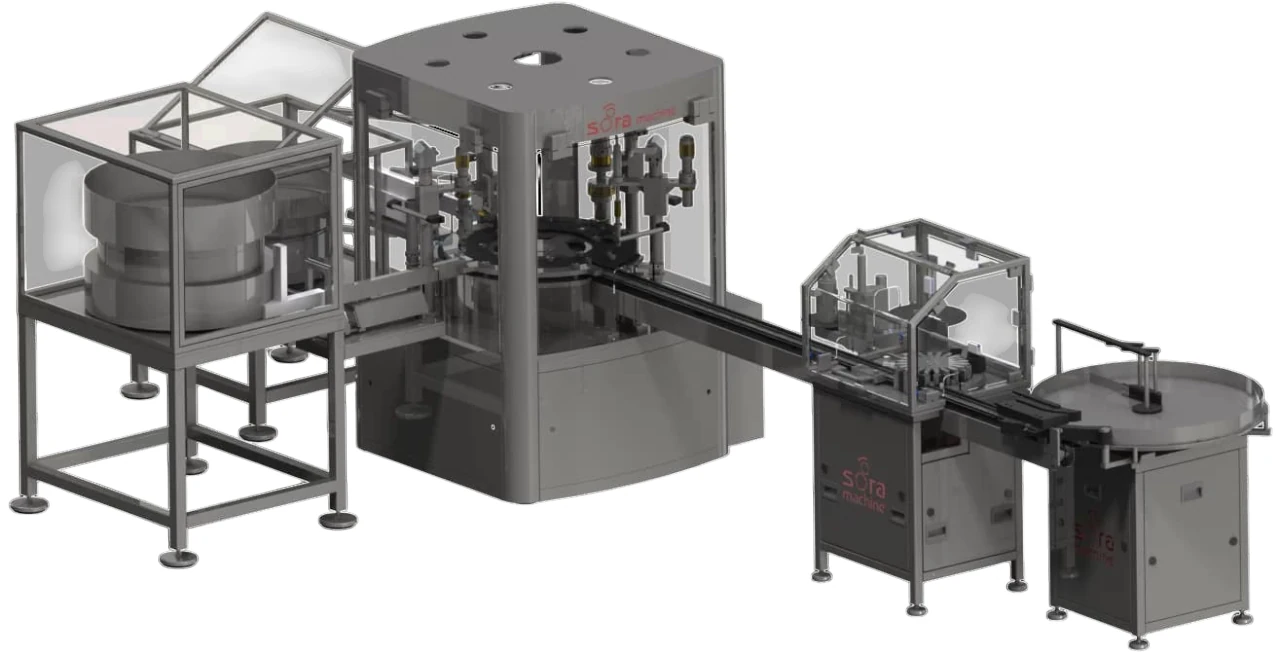

Safety is one of the most critical aspects of aerosol filling technologies. New regulations encourage manufacturers to develop safer and more sustainable solutions. New valve technologies that minimize explosion risks and leak-proof cap systems make products safer than ever. Consumer-friendly and secure products also strengthen brand trust.

Additionally, governments and international organizations are introducing new regulations on sustainable production. Compliance with these standards helps manufacturers minimize both environmental and legal risks.

How Do High-Speed Filling Systems Improve Efficiency?

High-speed liquid filling machines capable of filling thousands of cans per minute significantly boost production capacity. These rapid production processes allow businesses to manufacture more products at lower costs, creating a competitive advantage and strengthening market positioning.

Multi-line filling systems offer flexible production solutions by simultaneously filling different product varieties. This technology enables businesses to quickly adapt to various market segments.

What Does the Future Hold for Aerosol Filling Technologies?

In the future, artificial intelligence, automation, and eco-friendly solutions will become indispensable in aerosol filling technologies. Manufacturers will continue investing in innovative solutions to reduce costs and minimize environmental impacts.

Furthermore, the use of 3D printing technology in filling lines will increase. 3D printing presents a significant opportunity, particularly for producing customized valve and spray systems. With the rise of personalized products, brands are expected to develop tailored filling and packaging solutions for customers.

Aerosol filling technologies are evolving rapidly, offering new opportunities for manufacturers. Smart automation systems, sustainable materials, and advancements in safety standards are making the industry more efficient, eco-friendly, and reliable. Businesses that closely follow these trends will gain a competitive edge.

In the coming years, more sustainable, safer, and more efficient production processes will drive a major transformation in the aerosol filling industry. Companies that keep up with technology will strengthen their market presence while providing consumers with higher-quality and safer products.