In today’s competitive industrial environment, achieving the highest efficiency at every stage of the production process is crucial to the success of businesses. Liquid filling machines, which play a critical role in sectors such as food, pharmaceuticals, chemicals, and cosmetics, are particularly important in this context. Improving the efficiency of these machines not only increases production capacity but also directly impacts profitability by reducing costs. Let’s take a closer look at the key factors that will unlock the full potential of liquid filling machines and elevate your production processes to the next level.

The Future of Production: Automation and Smart Systems Driving the Efficiency Revolution

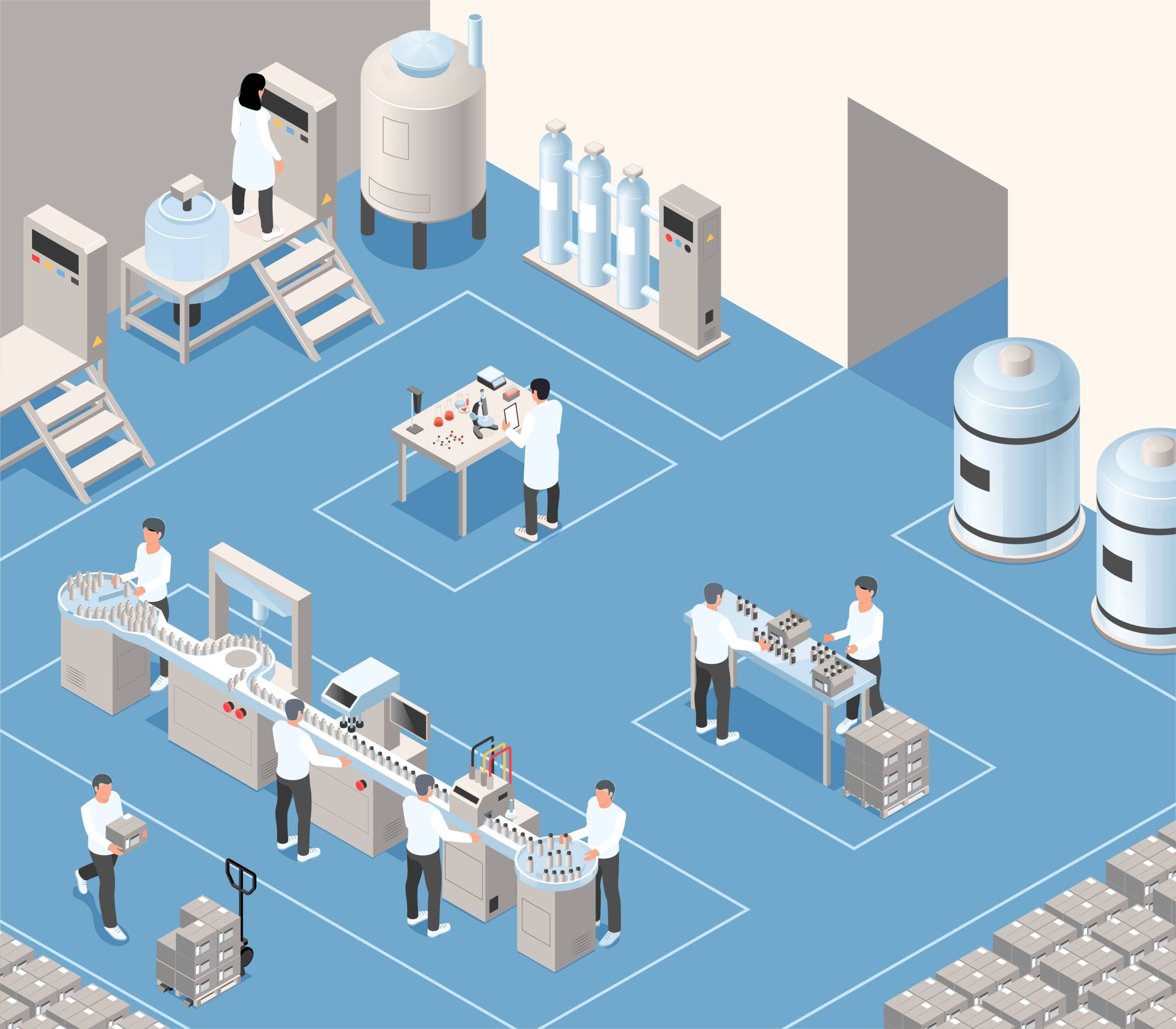

The innovations brought by Industry 4.0 are fundamentally changing the working principles of liquid filling machines. The integration of automation systems significantly reduces the need for human labor in production lines, while taking production speed and consistency to an unparalleled level. Imagine a production line where each product is filled with millimetric precision in seconds, and human error is almost eliminated. This is precisely what automation makes possible.

AI-powered smart sensors and automatic calibration systems optimize filling accuracy, ensuring that the same amount of liquid is present in each product. This not only enhances product quality but also reduces unnecessary material usage, thus lowering costs.

However, the benefits of smart systems don’t end here. With IoT (Internet of Things) solutions, machine performance can be monitored in real-time. This enables the early detection of potential failures and the implementation of predictive maintenance. A potential issue in the machines can be identified before it causes any disruption, preventing production interruptions. This results in a seamless and much more efficient production flow, providing a significant competitive advantage.

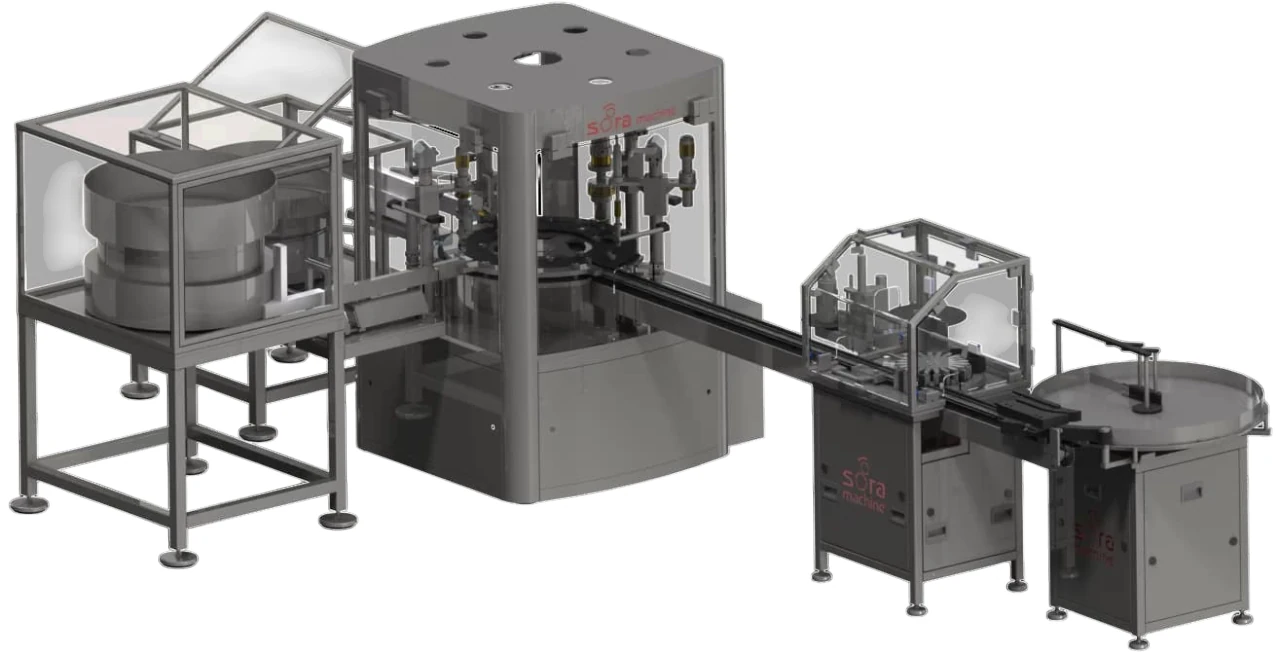

The Perfect Harmony of Speed and Accuracy: High-Performance Filling Systems

Two of the key performance indicators for liquid filling machines are speed and accuracy, which directly affect overall production efficiency. High-speed filling technologies, capable of filling thousands of products per minute, multiply the efficiency of your production lines. This is especially advantageous for businesses during high-demand periods and large-scale production.

However, speed alone is not enough. Accuracy is just as crucial. Modern liquid filling machines use precise filling valves and automatic leveling systems, ensuring flawless and consistent filling quantities for each product, minimizing product loss. This helps to prevent material waste and ensures consistent product quality.

Today’s advanced liquid filling machines are equipped with flexible systems capable of easily handling liquids with different viscosities (i.e., liquids with varying flow properties). This adaptability eliminates the need for separate lines for different products, such as various cosmetic makeup items, providing great convenience and efficiency in the production process. Therefore, these smart systems that optimize the time spent in cosmetic filling machines increase production speed while significantly reducing waste, thus lowering operating costs.

Excellence in Maintenance and Cleaning for Long-Lasting and Trouble-Free Production

For liquid filling machines to remain long-lasting and consistently perform at a high level, periodic maintenance is crucial. Routine maintenance and cleaning procedures prevent wear and tear on mechanical components, prevent potential breakdowns, and extend the overall lifespan of the machines.

In modern manufacturing facilities, time is of the essence. Therefore, rapid cleaning systems and CIP (Cleaning In Place) technologies minimize machine downtime while maintaining the highest hygiene standards. In industries such as food and pharmaceuticals, where hygiene is critical, these automatic cleaning systems ensure product quality and facilitate compliance with regulatory requirements. Quick and effective cleaning also eliminates contamination risks when switching between different products.

Production Lines Ready for the Future: The Power of Flexible and Modular Systems

In today’s rapidly changing market conditions, having production lines that are flexible and easily adaptable offers a significant advantage. Modern liquid filling machines feature modular structures that can easily accommodate different product types and packaging formats. This flexibility allows quick transitions between different packaging sizes and shapes, ensuring maximum efficiency in the production line.

This modular structure can also be easily updated with new technologies and scaled according to production capacity. In other words, businesses can easily expand their existing filling systems or integrate new-generation technologies in line with their growth goals. This way, companies can quickly adapt to changing market demands and continuously maintain a competitive edge.

Not Just Fast, But Smart: New Approaches to Energy and Raw Material Savings

An efficient filling system not only works at high speeds but also optimizes energy and raw material consumption. Low-energy consumption motors, smart pump systems, and precise filling technologies prevent unnecessary energy usage and material waste, significantly reducing operating costs.

Additionally, recovery systems used in modern liquid filling machines allow excess liquid generated during production to be returned to the system, minimizing raw material loss and creating an eco-friendly production process. These systems reduce friction and potential product losses, contributing to the circular economy and helping businesses achieve their sustainability goals.

No Compromise on Quality: Advanced Control Mechanisms and Data Analytics

Ensuring quality at every stage of the production process is fundamental to customer satisfaction and maintaining brand reputation. Advanced quality control systems meticulously monitor every stage of the liquid filling process, minimizing error rates. Cameras, sensors, and laser-based detection systems can instantly detect any anomalies by monitoring the filling quantity and sealing quality.

However, quality control goes beyond simply detecting errors. AI-powered data analytics thoroughly analyzes the production data, offering opportunities for improvement. Continuously monitoring machine output efficiency and using this data for optimizations helps businesses gain a competitive advantage and consistently achieve better results. This way, production processes are continuously improved, and efficiency is maximized.

8 Steps to Improve Efficiency in Production!

To achieve noticeable improvements in your liquid filling processes and gain an edge in the competition, consider the following suggestions:

- Conduct a Detailed Needs Analysis: Clearly identify your current filling processes and the bottlenecks you face. Understanding which areas need improvement is the first step in making the right technological investments. Consider factors like your production volume, the characteristics of the liquids to be filled, and packaging variety.

- Start with Pilot Projects: Before implementing new automation or smart systems on a large scale, test the technology’s effectiveness and compatibility with a small pilot project. This will help you minimize risks before making large investments.

- Prioritize Staff Training: To effectively use new technologies and systems, it is critical that your staff has the necessary knowledge and skills. Organize comprehensive training programs to facilitate the adaptation of your employees to new systems.

- Review and Update Maintenance Plans: Evaluate whether your current maintenance plans are sufficient. Develop more frequent and comprehensive maintenance routines based on manufacturer recommendations. Use predictive maintenance technologies to identify potential failures in advance.

- Conduct Energy Efficiency Audits: Analyze the energy consumption of your filling machines and related equipment. Identify potential areas for energy savings and consider switching to low-energy equipment or optimizing existing systems.

- Strengthen Collaboration with the Supply Chain: Work closely with your packaging suppliers. Keep in mind that the quality and standards of packaging can affect the filling process. Using compatible and high-quality packaging materials can reduce disruptions in production.

- Create a Continuous Improvement Culture: Regularly analyze production data to identify inefficiencies and areas for improvement. Create a continuous improvement-focused culture by considering feedback from your employees.

- Follow Industry Developments: Stay up to date with the latest developments in liquid filling technologies and automation. Attend industry fairs to discover new technologies and potential business partners.

Increasing efficiency in liquid filling machines is not just about using existing technologies but also about making forward-thinking investments and embracing continuous improvement principles. By focusing on automation, smart systems, efficient maintenance, flexibility, energy savings, and advanced quality control mechanisms, businesses will lower production costs and offer higher-quality and more consistent products, thus rising to a leading position in the industry.