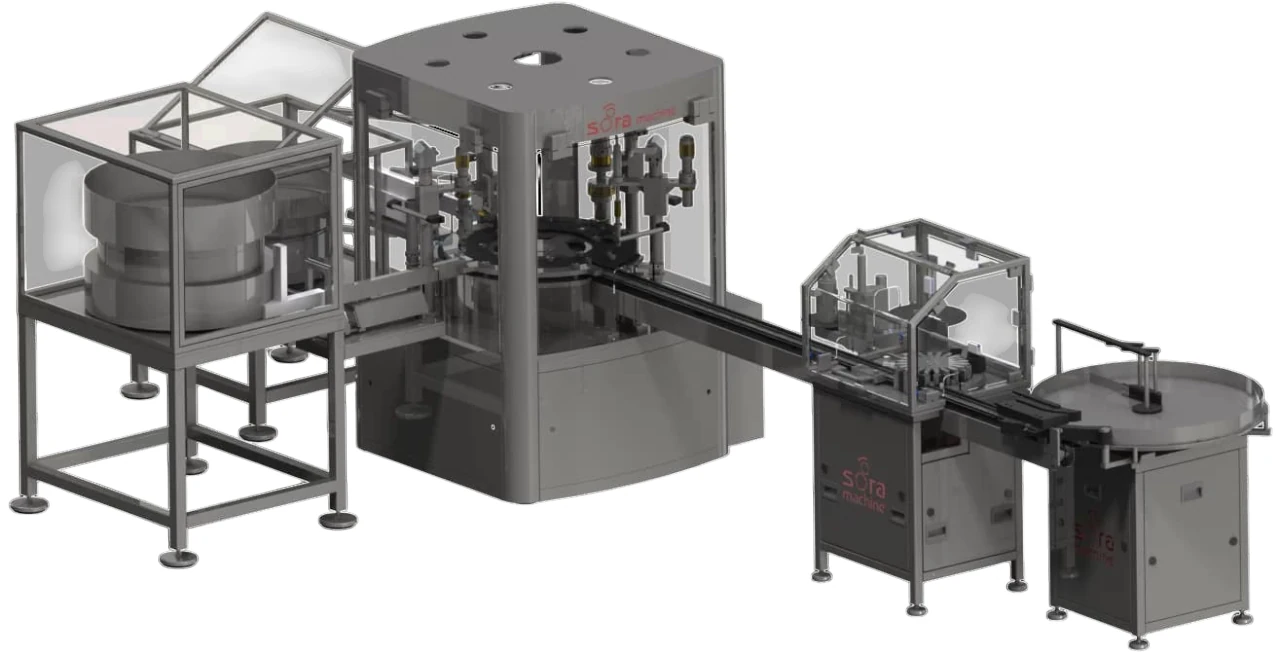

While the demand for aerosol products increases day by day, one of the most important reasons for this increase is the interest of users in the practicality and hygienic use of these products. Aerosol sprays find their place in many areas, from cosmetics to cleaning, from food to industrial use. This wide range of applications makes automation in production lines mandatory for manufacturers to respond to demands more quickly and efficiently. At this point, automatic aerosol filling machines come into play.

Manual or semi-automatic filling systems used years ago cannot meet today’s rapid production needs. Automatic machines, on the other hand, fill this gap with their advantages such as high capacity, low labor requirement, and consistent quality. Companies wishing to meet the increasing demand are modernizing their production processes by choosing automatic filling machines.

Benefits of Automatic Aerosol Filling Machines

Automatic aerosol filling machines contribute to production processes in many ways. These machines offer faster, more reliable, and more economical solutions compared to manual and semi-automatic systems. Here are some of the main advantages of automatic systems:

-

High Production Volume:

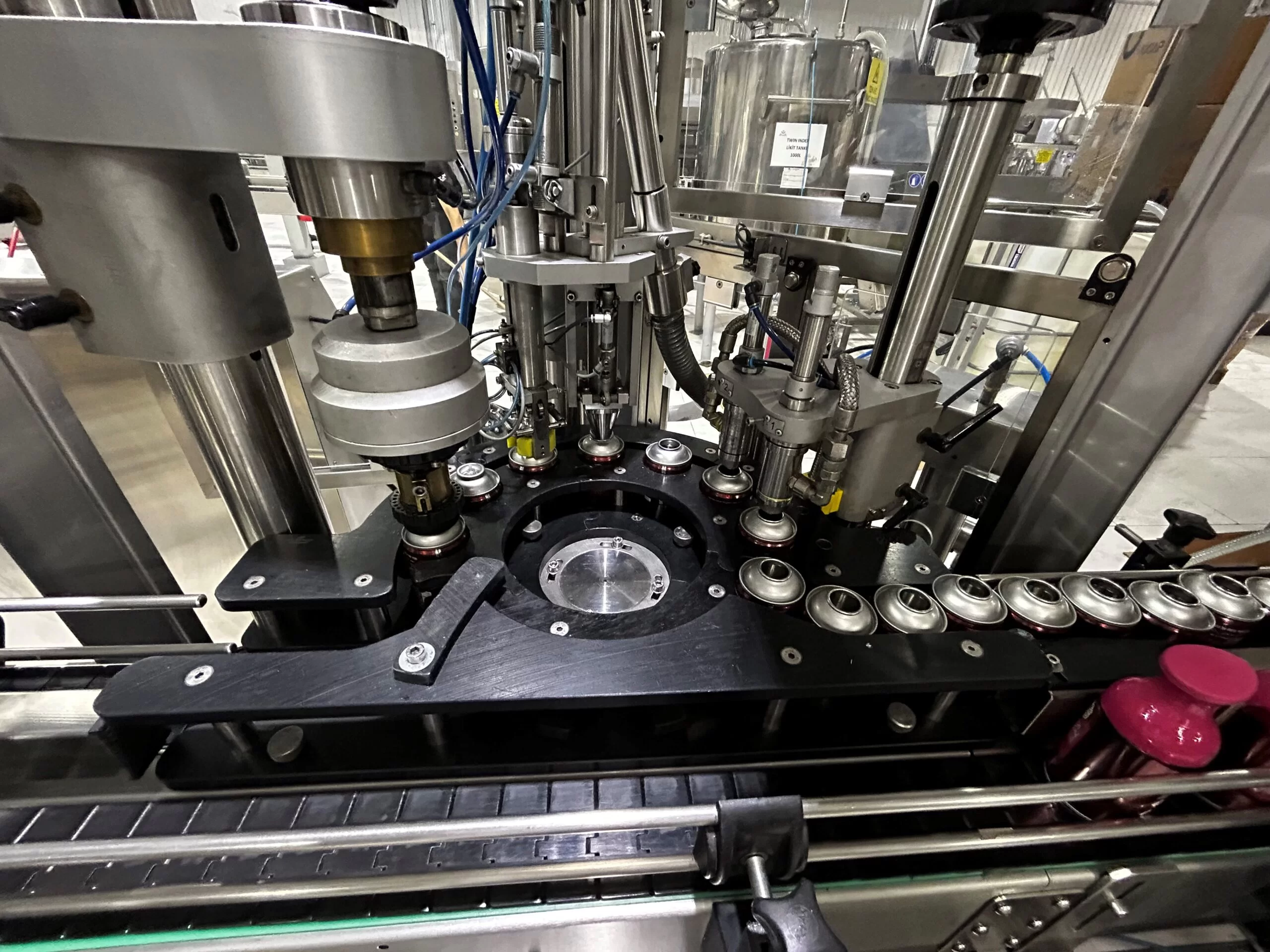

Automatic machines have the capacity to fill a large number of aerosol cans per minute. This makes them ideal for large-scale manufacturing factories. Thanks to the production speed, large orders can be completed in a short time.

-

Reduced Labor Needs:

While manual systems require worker intervention for each filling operation, automatic machines carry out the process themselves. This reduces the need for personnel, which in turn lowers labor costs.

-

Low Error Rate:

Automatic systems ensure homogeneous production by using the same amount of product in each filling. This ensures the standardization of product quality and increases customer satisfaction.

-

Safe and Hygienic Production:

Automatic machines operating with a closed system minimize the contact of products with external factors. This means both a safe and hygienic production process.

Comparison with Non-Automatic and Semi-Automatic Machines

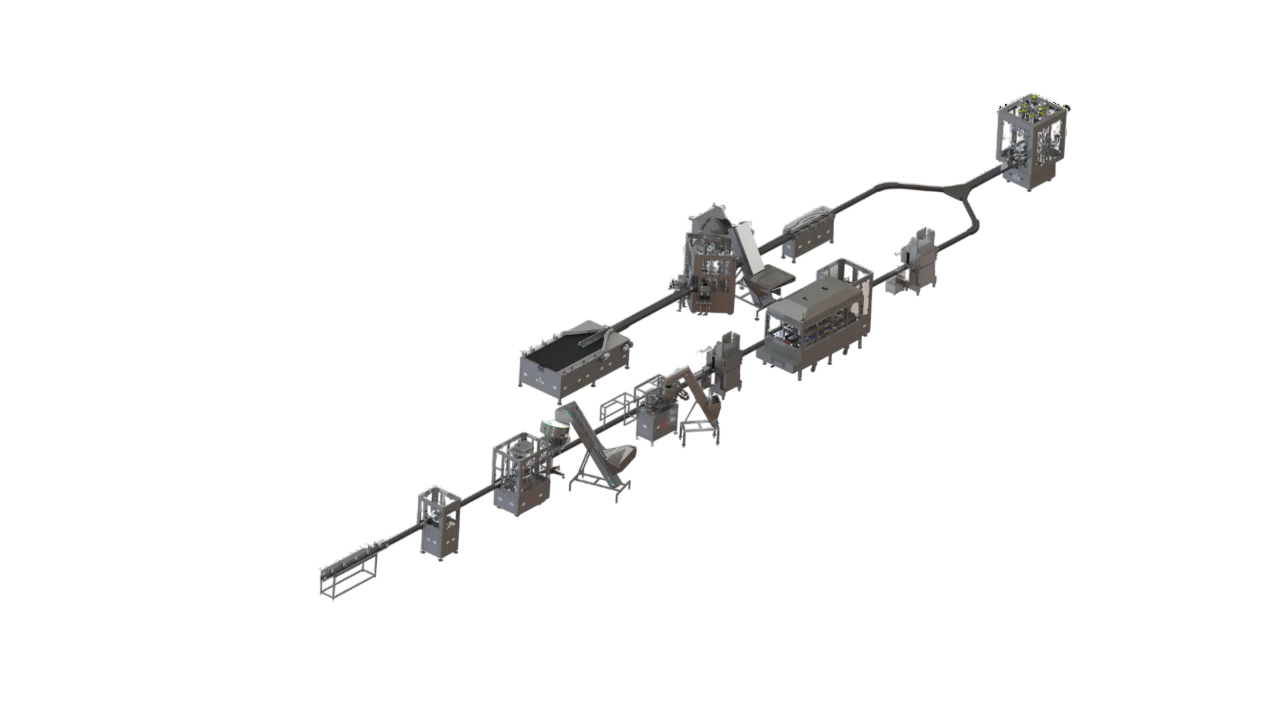

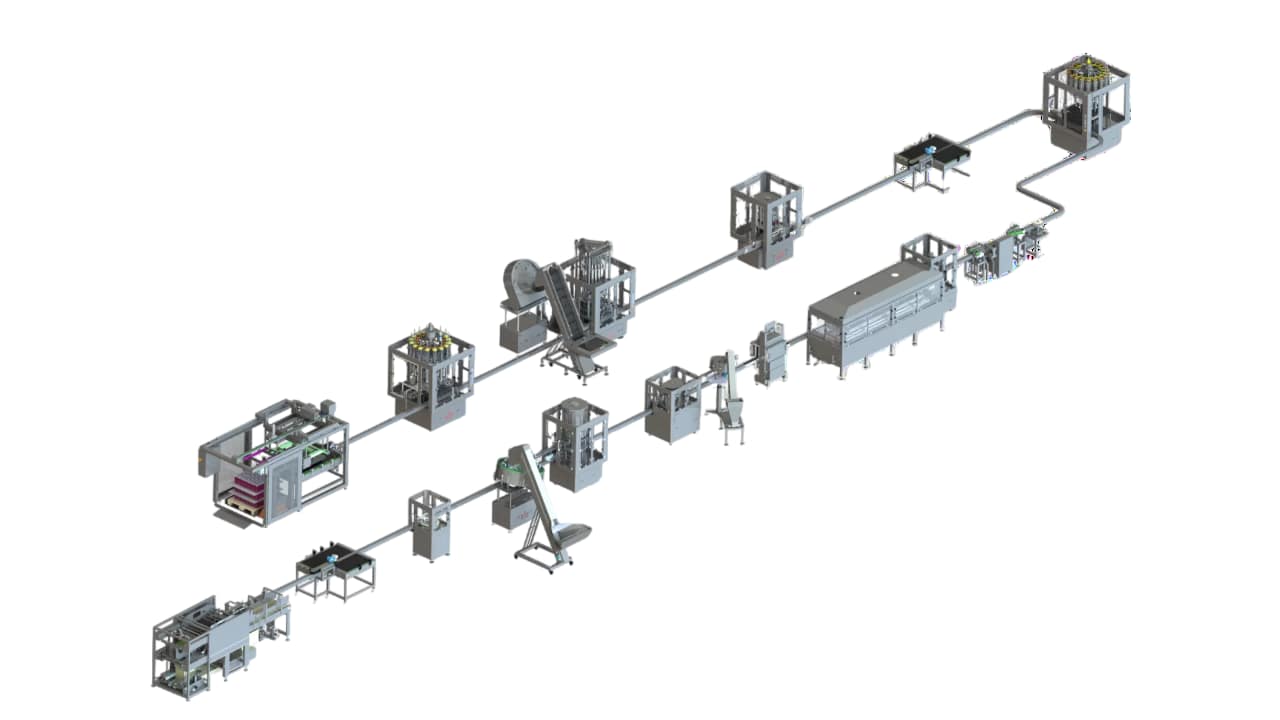

Aerosol filling machines are generally divided into three main categories: manual, semi-automatic, and fully automatic. In manual machines, every step is carried out by human hand. In semi-automatic systems, some processes are carried out by machines, while others require worker intervention. However, the common point of these systems is their low production capacity and the need for more manpower.

Automatic machines, on the other hand, eliminate the limitations offered by these two categories. They can perform almost the entire process on their own, which makes them more attractive to manufacturers. Especially for companies receiving intense orders and wishing to increase their production capacity, automatic systems are indispensable.

Changing Production Processes with Automatic Aerosol Filling Machines

The aerosol industry continues to grow, especially with the development of sectors such as cleaning, cosmetics, and food. Products such as spray cleaning products used in homes, hair sprays, deodorants, and cooking sprays have now become a part of daily life. At the same time, technical sprays and lubricants used in the industrial field also support this demand.

In the face of this increasing demand, it is becoming inevitable for manufacturers to switch to automatic filling machines in order to produce both quickly and with high quality. These machines not only increase production speed but also make it easier for businesses to adapt to changing market conditions and customer demands. Today, some advanced automatic machines can fill hundreds of cans per minute and can operate continuously for long periods.

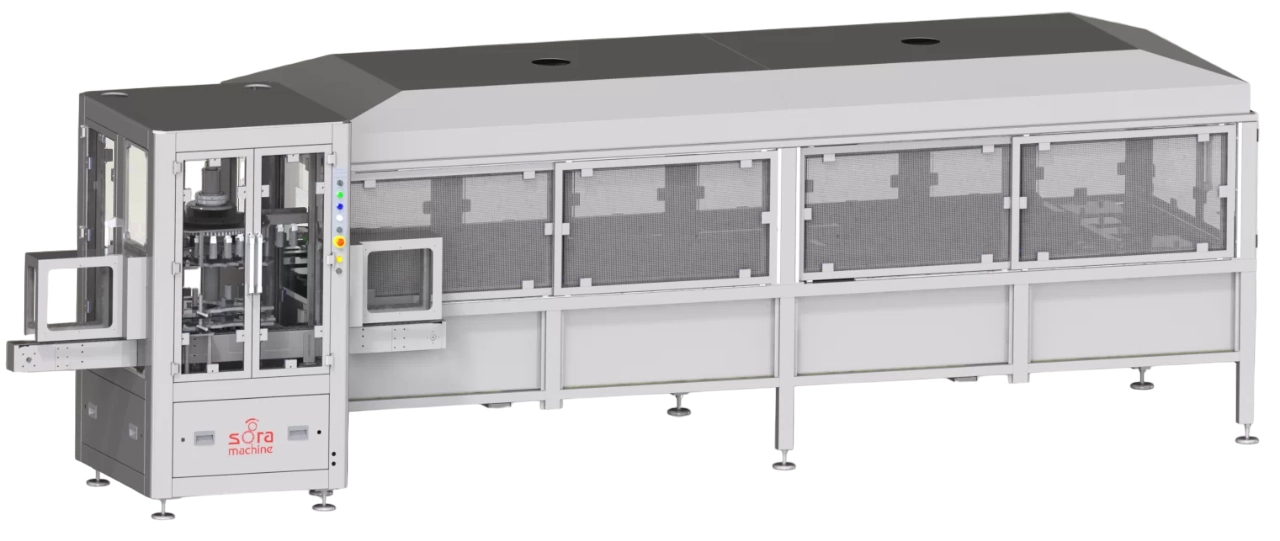

Global Supply and Easy Access

Another important advantage is that these machines are now much easier to obtain. Both domestic and foreign manufacturers offer automatic filling machines with various capacities and features. This allows manufacturers to easily choose a system suitable for their scale. Moreover, thanks to technological developments, the installation, use, and maintenance of the machines are becoming more user-friendly every year. In this way, companies using these machines can manage their systems without having to establish a large team with technical knowledge.

Aerosol Production Strengthened by Automation

Automatic aerosol filling machines not only increase production speed but also reduce costs, standardize quality, and increase the competitiveness of companies. Responding quickly to increasing consumer demands is now easier thanks to these machines. This technology, which is developing day by day, allows aerosol manufacturers to move towards the future with more solid steps.

Companies can achieve a significant transformation in their production processes by purchasing these machines. These machines, available in both domestic and international markets, are diversified according to different needs and budgets. This allows companies of all sizes to benefit from automation technologies.