In the packaging sector, operations are carried out with practicality and efficiency, and one of the most effective methods in this field is aerosol filling systems. From your favorite hairspray to the spray paints you used for your latest DIY project, there is a silent but powerful contribution of aerosol filling machines behind these products. So, what exactly is an aerosol filling machine, and how does it work? Let’s explore this technology in all its details!

What is an Aerosol Filling Machine?

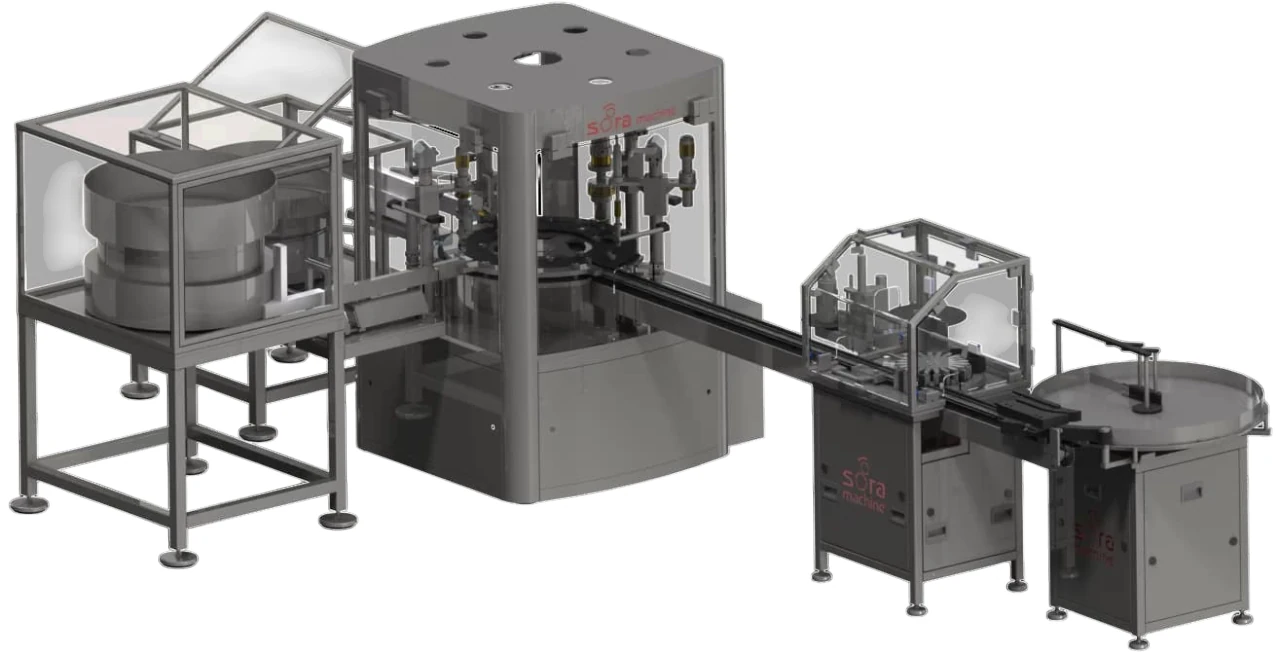

Aerosol filling machines are specialized equipment designed to fill liquid, cream, or gaseous products into aerosol cans under pressure. There are manual models for small-scale production, semi-automatic models for medium-sized businesses, and fully automatic models for high-volume production. In short, these machines are the key to packaging your products effectively, safely, and professionally.

What are the Types of Aerosol Filling Machines?

What are the Manual, Automatic, and Semi-Automatic Aerosol Filling Machine Options?

- Manual Machines: Ideal for small businesses or hobby use. Although they have a low production volume, they offer the user the opportunity to fully control the process.

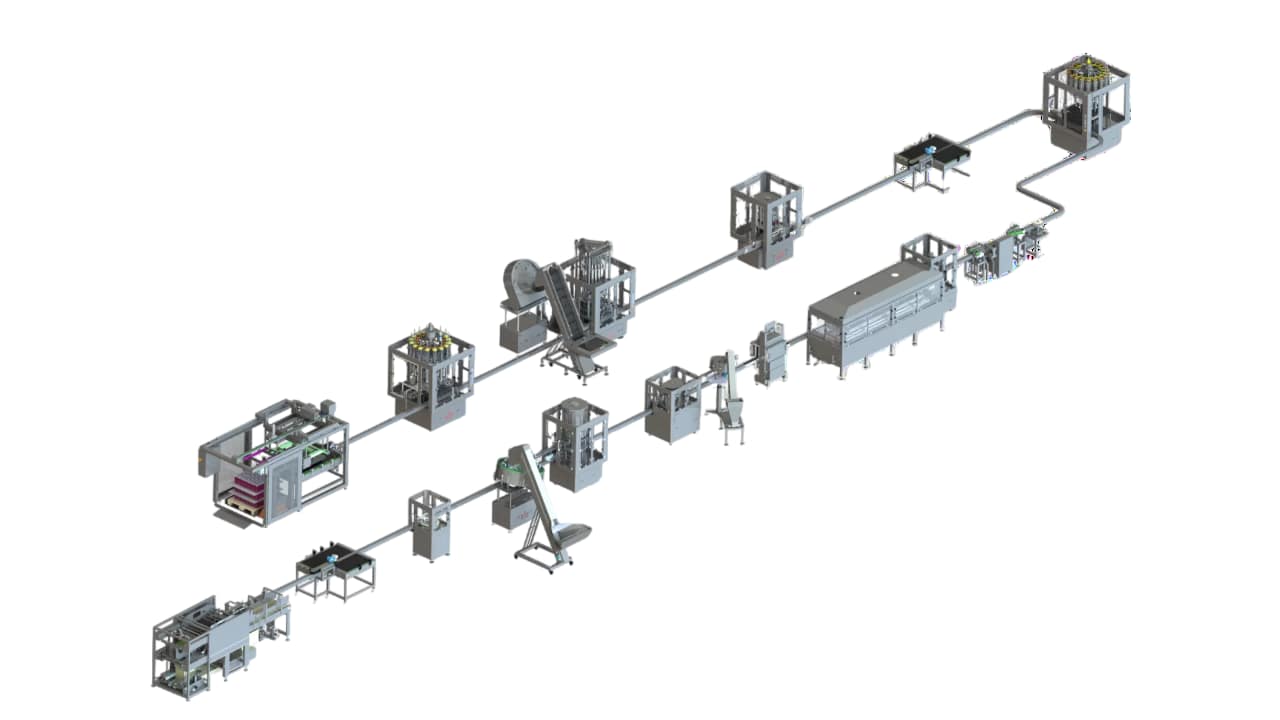

- Automatic Machines: Designed for facilities with high production capacity. Human intervention is minimal, and they can quickly fill hundreds of cans per hour.

- Semi-Automatic Machines: Combine the advantages of both automatic and manual systems. They are an excellent stepping stone for medium-sized manufacturers.

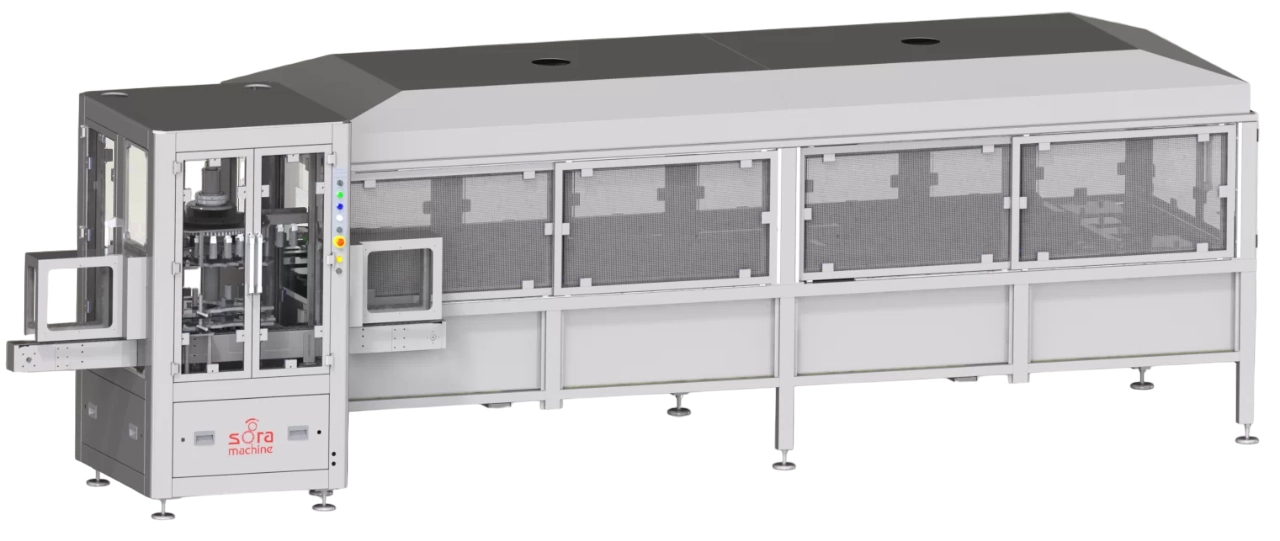

Standard Aerosol Filling Machine

This type of machine, widely used in various sectors, stands out with its simple design and versatile usage.

BOV (Bag-on-Valve) Filling Machine

The BOV filling machine is developed for products that need to be stored under pressure but use a bag system instead of classic cans. It is especially preferred in medical and special cosmetic products.

Under Cap Filling Machine

As the name suggests, the under cap filling machine fills aerosol cans from under the cap. It allows different product types to be easily changed on the same line. Flexibility is the biggest advantage here!

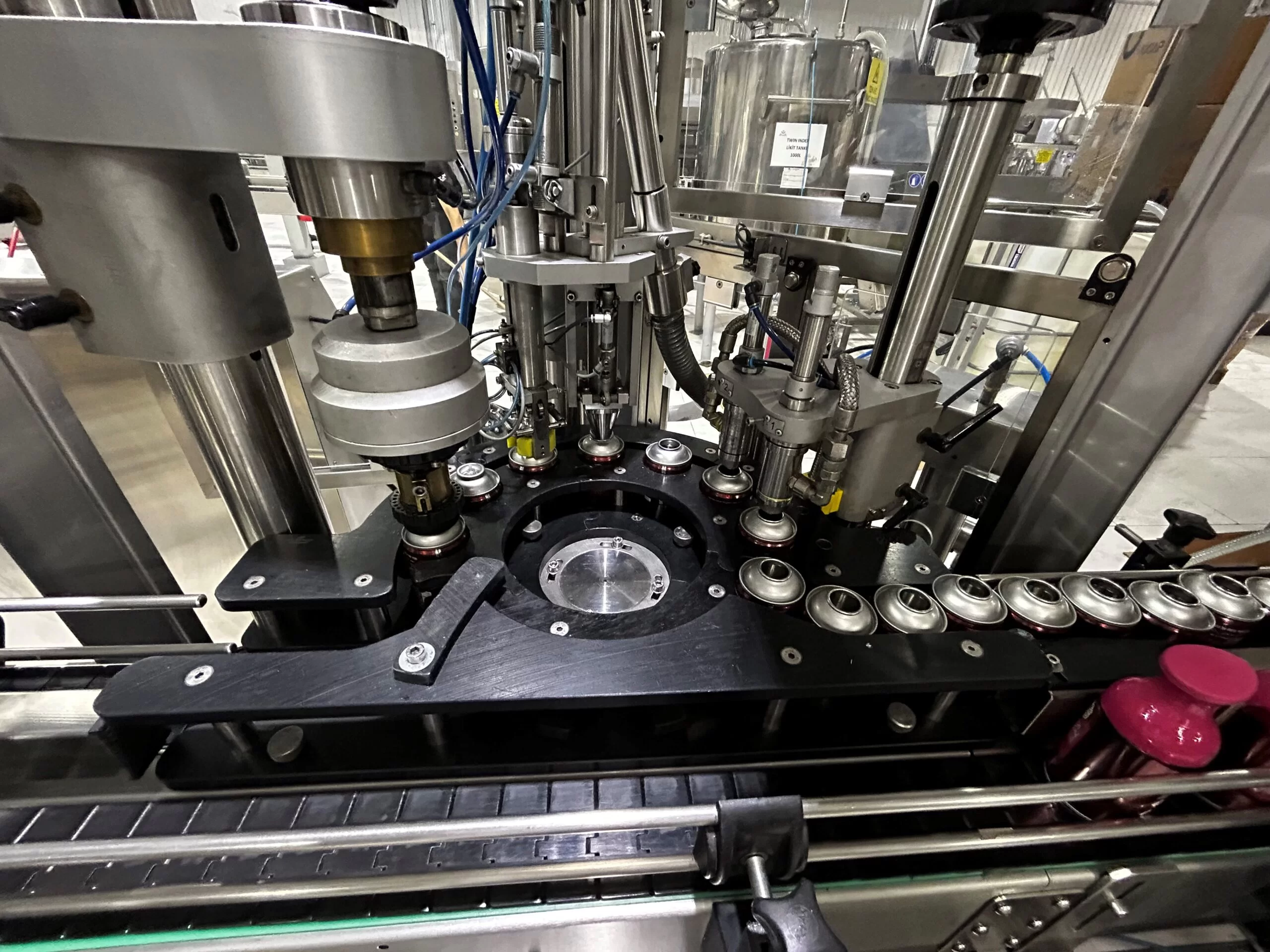

What are the Basic Parts of Aerosol Filling Machines?

- Pressure Control Systems: Ensure that the correct pressure is maintained during filling. This is critical for both safety and product quality.

- Filling Nozzles: Ensure that the product is transferred into the can precisely. They minimize errors such as spillage or underfilling.

- Capping Mechanisms: Ensure that the cans are tightly sealed after filling, guaranteeing product safety.

How Do Aerosol Filling Machines Work?

These machines work like a truly flawless symphony:

- Empty cans are placed on the production line.

- The product is filled into the can under controlled pressure.

- Then, the capping mechanism is activated, and the can is sealed.

The whole process may show minor differences depending on the product’s structure and the type of machine used. But the goal is always the same: safe, fast, and consistent production.

What are the Advantages of Aerosol Filling Machines?

Increase in Production Speed

These machines, which can complete processes that might take hours with manual methods in seconds, significantly increase your production capacity.

Quality and Consistency

The fact that each can is filled with the same amount and the same pressure is the basis of customer satisfaction and brand reliability. These machines adhere to standards.

Precision and Accuracy

Dosage is very important, especially in medical or cosmetic products. Aerosol machines operate with micron-level precision at this point.

Decrease in Labor Costs

Automation means more production with less labor. This reduces operating expenses and increases efficiency.

What are the Usage Areas and Products of Aerosol Filling Machines?

Personal Care Products

- Deodorant

- Hairspray

- Body spray

- Shaving foam

- Sunscreen

Household Cleaning Products

- Cleaning sprays

- Air fresheners

- Insecticides

- Fabric sprays

- Oven cleaners

Automotive Sector

- Engine cleaner

- Spray lubricant

- Tire inflator

- Brake cleaner

- Touch-up paints

Food Sector

- Whipped cream

- Cooking sprays

- Cheese foam

- Chocolate mousse

- Spray sauces

Things to Consider When Choosing the Right Aerosol Filling Machine

Quality & Price Balance

Although high-quality machines may seem costly at first glance, they more than pay for themselves in the long run with low maintenance and failure rates.

Production Volume

If you are going to do high-volume production, automatic machines will provide you with time and cost advantages. For lower volumes, manual or semi-automatic options may be sufficient.

Product Type

Details such as product density, gas type, and spray pattern should be considered when determining the appropriate machine.

Manufacturer Reliability

Evaluate user reviews, warranty conditions, and technical support services. A reliable manufacturer is not just a machine supplier but also a long-term business partner.

Aerosol filling machines are the unsung heroes that ensure products reach the end consumer safely and aesthetically. Whether you are in the personal care, automotive, or food sector, you can increase your production quality and take your operational efficiency to the highest levels by choosing the right machine.

Frequently Asked Questions About Aerosol Filling Machines

-

What products can be filled with aerosol filling machines?

Liquid, foam, or gas products in many sectors such as cosmetics, cleaning, automotive, and food can be filled with these machines.

-

Which type of filling machine would be suitable for me?

You can choose the most suitable model by determining your production volume, product type, and automation needs.

-

Is it safe to use?

Yes, aerosol machines are quite safe as long as the manufacturer’s instructions are followed.

-

Can I fill different products with the same machine?

Some machines are multi-purpose, but product-machine compatibility should always be checked.

-

What is the average price of an aerosol filling machine?

Manual filling machines and fully automatic filling systems can have different prices depending on their features. Therefore, long-term savings should be considered when making a choice. Click here to get a price quote for a Sora machine aerosol filling machine!