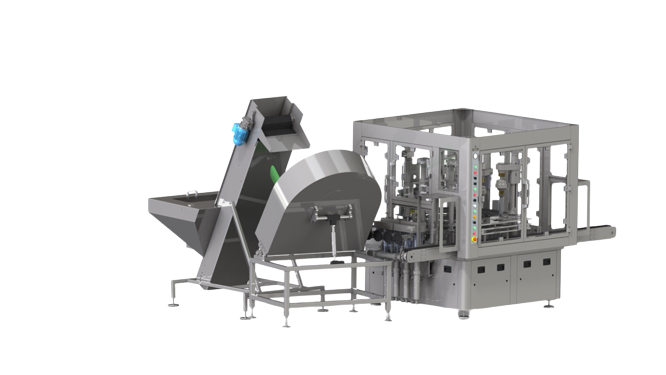

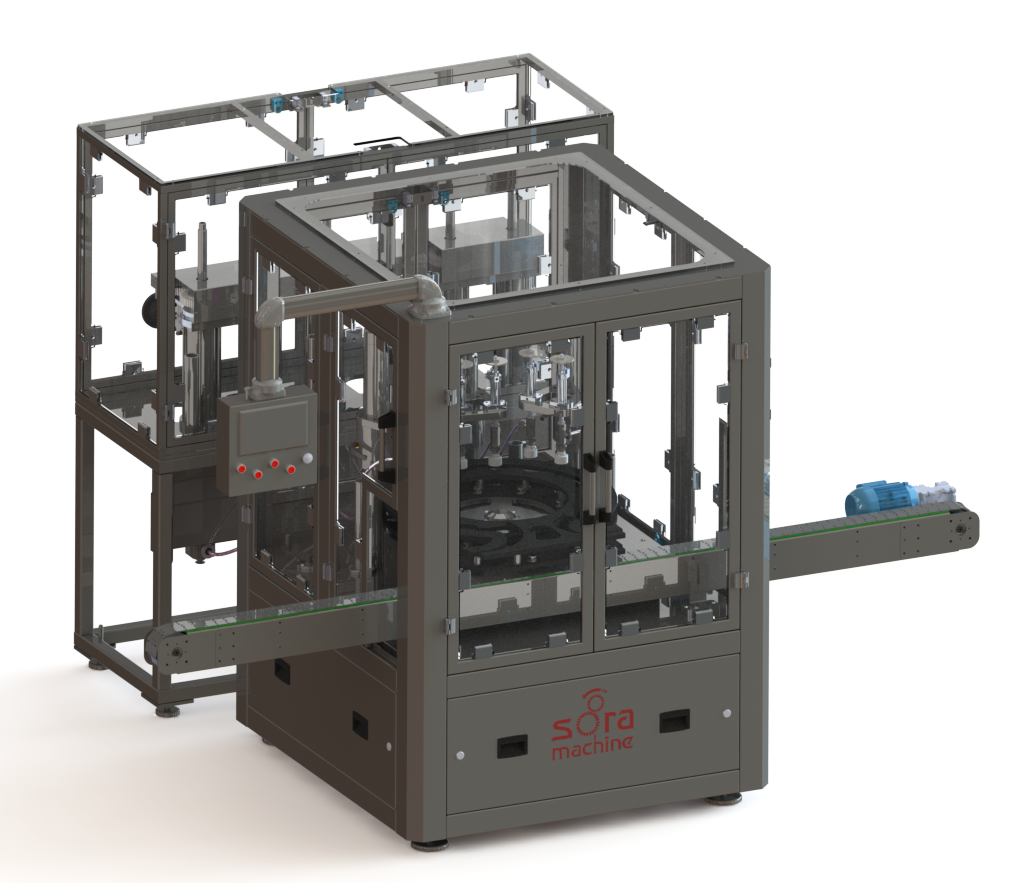

BOV MAK: The Meeting Point of High Efficiency and Hygiene

BOV MAK is an advanced aerosol filling system based on innovative Bag-On-Valve (BOV) technology, integrable into modern production lines. By physically separating the product from the propellant, it maximizes both content safety and user satisfaction. Developed by Sora Machine, BOV MAK is safely used in many sectors, from cosmetics to health, cleaning to food.

Key Advantages of Bag-On-Valve Technology

Superior Hygiene and Protection

Thanks to the valve system inside the bag, the product does not come into contact with the inner surface of the metal can or the propellant. This structure preserves the integrity of the product even in applications requiring sterility. At the same time, quality problems such as microbial contamination and oxidation are completely eliminated.

One Hundred Percent Product Usage

The unique structure of the BOV system prevents the product from being trapped inside the can. The user can consume the product until the last drop. This not only increases customer satisfaction but also facilitates recycling processes.

Sustainable and Environmentally Friendly

Unlike classic aerosol systems, BOV technology can work with environmentally friendly gases and minimizes the use of preservatives in the product content. The separation of gas and product also ensures that the product packaging is easily recyclable.

Technical Excellence of BOV MAK

Developed with the engineering power of Sora Machine, BOV MAK machines are optimized for high-performance production.

Automatic Control and Precise Filling

Thanks to the PLC-controlled system infrastructure, all parameters such as filling volume, pressure, and speed are managed digitally. This minimizes the error rate while making the production process extremely stable and safe.

High Production Capacity

BOV MAK can fill 20 to 80 cans per minute, depending on the model. This flexibility makes it suitable for both small-scale and large-volume production facilities.

Modular and Flexible Design

BOV MAK systems, which can be supported by optional modules, can be easily integrated into existing production lines. This shortens the return on investment period and increases production capacity.

Application Areas: Multi-Sector Power

Cosmetic and Personal Care Products

Ideal for products such as deodorants, hair mousses, shaving gels, and care sprays. By preventing the product from coming into contact with air, the shelf life is extended, and formula stability is maintained.

Pharmaceutical and Medical Products

An excellent solution for sensitive products such as nasal sprays, wound care solutions, and inhalers. BOV systems make a difference in these areas where sterility and dosage accuracy are critical.

Food and Dietary Supplement Products

Contents such as spray oils, food additives, and aromatic products are offered to consumers without compromising freshness.

Industrial and Household Cleaning Products

Provides smooth spraying and controlled consumption in cleaning products such as disinfectants, surface cleaners, and glass sprays.

Why BOV MAK?

- Design Compliant with International Standards

- Stable Performance Even at High Production Speeds

- User-Friendly Control Interfaces

- Low Maintenance Needs and Long Lifespan

- Strong After-Sales Support with Sora Machine Expertise

With BOV MAK, Sora Machine offers manufacturers not just a machine; but also high-quality production, less waste, and greater customer satisfaction. This technology, which combines local production power with global standards, is an investment opportunity that will take your brand one step further. Contact Sora Machine to take advantage of these technologies!