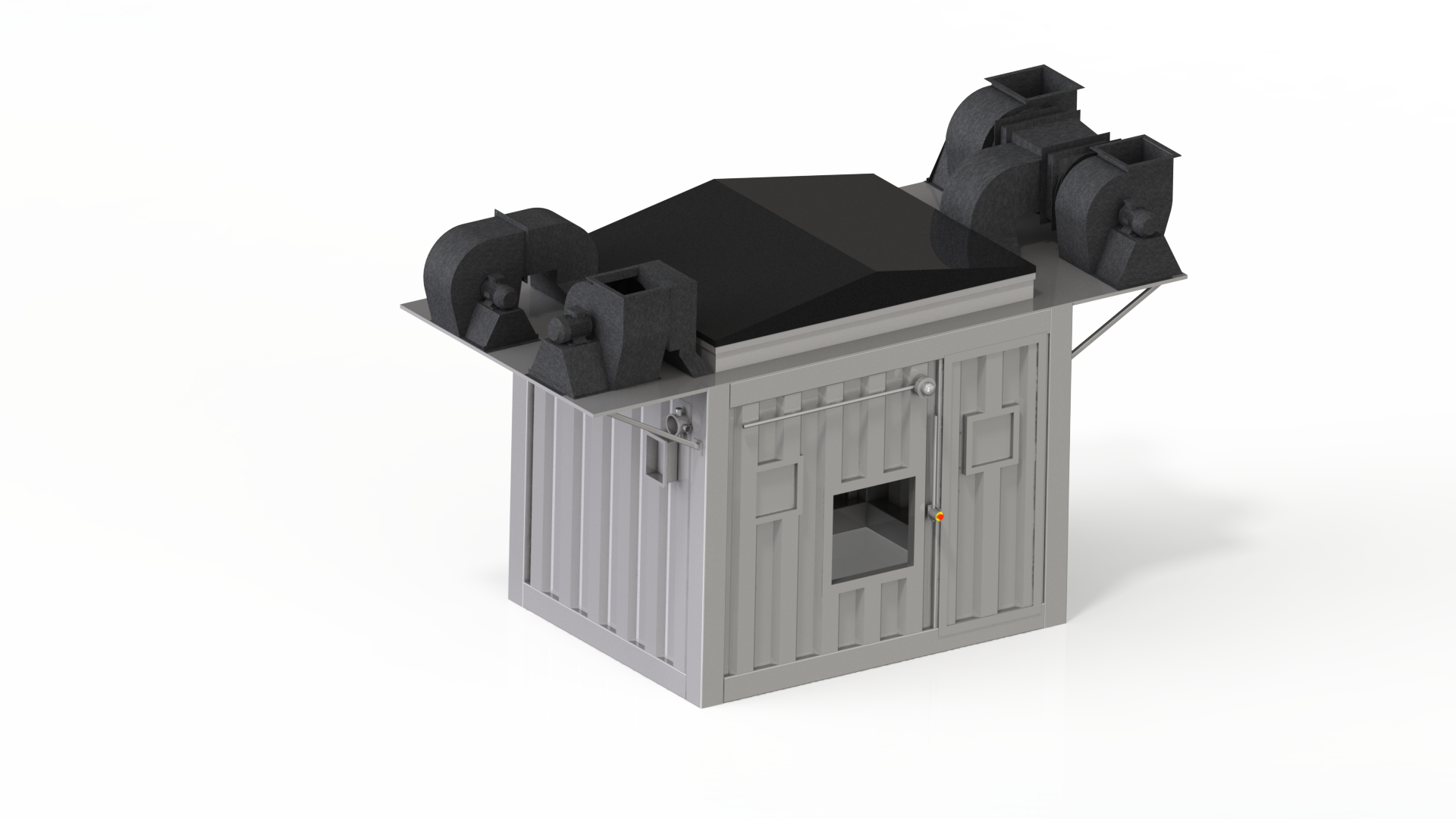

Sora Machine Safety Devices: How is Safety Ensured in Production?

While Sora Machine is known for its expertise in aerosol filling machines, it also integrates devices into its systems to maximize safety in production processes. Safety devices are critical for minimizing potential risks on the production line, ensuring operator safety, and maintaining production quality.

Which Safety Devices Are Available?

Sora Machine aims to keep the production environment under control with the safety devices used in its aerosol filling machines. These devices are designed to detect and intervene in potential hazards that may occur during production. Key safety devices include pressure relief valves, gas leak detection systems, emergency shutdown devices, temperature and pressure sensors, and safety interlock systems.

Pressure Relief Valves: How is Overpressure Controlled in Production?

Pressure relief valves control sudden pressure increases that may occur in the system during the filling process. These devices automatically activate when a certain pressure level is reached, releasing excess pressure. This prevents damage to equipment and potential explosions.

Gas Leak Detection Systems: How is Safety Maximized?

The safe management of propellants used in aerosol filling machines is of great importance. Gas leak detection systems instantly identify any gas leaks that may occur on the filling line and provide warnings, allowing for emergency intervention. These systems play a critical role in both operator safety and the reduction of environmental risks.

Emergency Shutdown Devices: How is the System Protected in Sudden Situations?

In the event of an unexpected situation during production processes, emergency shutdown devices are activated. These devices ensure the safe shutdown of the entire system and provide operators with time to intervene. Emergency shutdown systems are particularly critical in environments where high pressure and gas are used.

Temperature and Pressure Sensors: How is Continuous Monitoring Performed?

Continuous monitoring of temperature and pressure values within the system helps to detect potential hazards in production at an early stage. These sensors provide automatic warnings when values above or below the determined limits are observed, allowing operators to intervene. This allows for the immediate control of sudden changes in production.

Safety Interlock Systems: How is Operator and Equipment Safety Ensured?

Safety interlock systems ensure that filling machines and peripheral equipment are kept under control. These systems prevent machines from operating unless certain conditions are met, preventing incorrect operator intervention or accidents. The system automatically locks down in emergency situations, preventing damage to both equipment and operators.

What are the Operating Principles of Safety Devices?

Safety devices are integrated systems, each designed to perform a specific function. For example, pressure relief valves predetermine the maximum pressure levels in the system and automatically activate when this value is exceeded. Gas leak detection systems, on the other hand, instantly detect the presence of leaks in the environment based on chemical properties and sensor technologies. The operating principles of these devices are developed in accordance with international safety standards and require regular maintenance and calibration.

Which Factors are Important for Increasing Safety in Production?

The correct integration, regular maintenance, and operator training of devices are of great importance for increasing safety in production processes. Firstly, regular testing and calibration of all safety devices ensures that the system operates correctly under all conditions. Secondly, operators having sufficient knowledge about the functions of these devices enables rapid and effective intervention in potential hazards. Finally, the digitalization of the system and automatic control mechanisms ensure that monitoring and warning systems are kept active at all times, maximizing production safety.

How are Production Processes Protected with Sora Machine’s Safety Devices?

Sora Machine ensures both operator safety and equipment reliability in the production process through the integration of safety devices. Pressure relief valves on the production line control sudden pressure increases, while gas leak detection systems provide early warnings against leakage risks. Emergency shutdown devices stop the entire operation in critical situations that may occur in the system, preventing large-scale accidents. Additionally, temperature and pressure sensors and safety interlock systems allow for continuous monitoring and automatic intervention. Thanks to this integrated structure, potential hazards in the production process are minimized, creating an uninterrupted production line.

How is Safety Ensured with Technical Support and Maintenance Services?

Regular maintenance and technical support services are vital for the effective operation of safety devices. Sora Machine provides customer satisfaction with services including the installation, periodic maintenance, troubleshooting, and operator training of safety devices. The technical support team works closely with customers at every stage, from the installation to the commissioning of the devices, preventing potential disruptions. Thus, no security vulnerabilities remain on the production line, and operators feel safe.

What are the Trends in Safety Technologies for the Future?

Today, digitalization and automation are revolutionizing the manufacturing sector. Sora Machine closely follows these trends and continuously develops its safety devices. In the future, remote monitoring systems, artificial intelligence-supported warning mechanisms, and more sensitive sensor technologies are among the innovations that will increase the safety of the production line. These technological developments will not only minimize existing risks in production but also identify potential hazards in advance, allowing operators to intervene in a timely manner.

How is Safety Ensured in Production with Sora Machine Safety Devices?

The safety devices offered by Sora Machine play a critical role in the production of aerosol filling machines. Pressure relief valves, gas leak detection systems, emergency shutdown devices, temperature and pressure sensors, and safety interlock systems control all potential risks on the production line, ensuring the safety of both operators and equipment. Supported by regular maintenance, technical support, and operator training, this integrated system offers uninterrupted operation, high efficiency, and optimum safety levels in production. Furthermore, future-oriented investments in digitalization and automation further develop Sora Machine’s safety devices, enabling it to stand out in the sector by offering innovative solutions in production.

Thanks to this comprehensive structure, Sora Machine‘s safety devices both increase production quality and minimize potential hazards. This system, which detects risks in advance and activates intervention mechanisms, is the key to creating a safe working environment in modern production facilities.