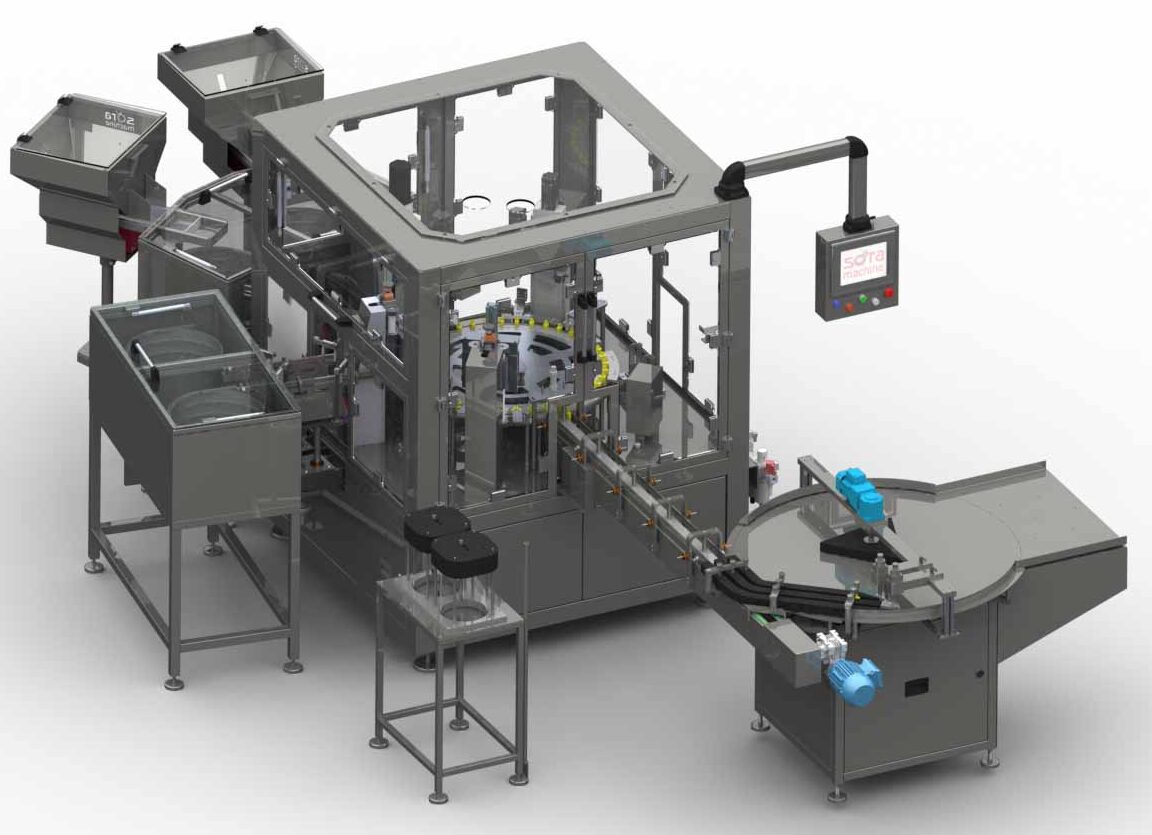

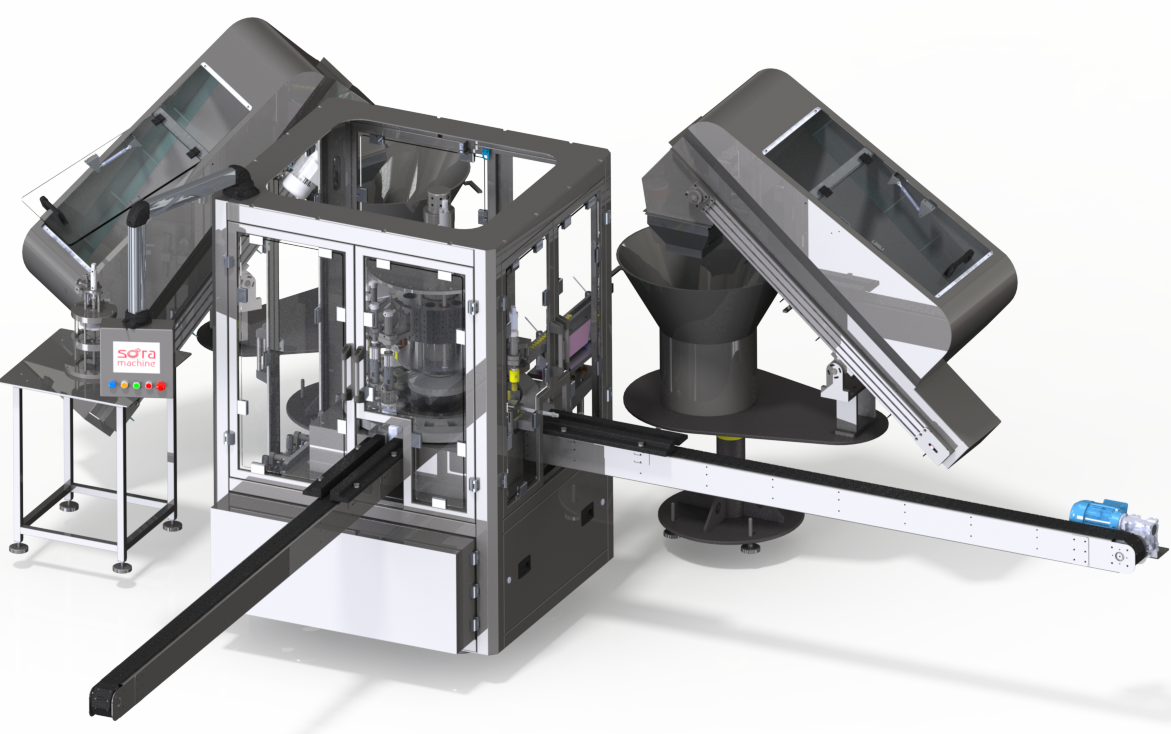

High Tech Cosmetic Filling Machine Solutions That Add Value to Your Production

The cosmetics industry is a field where manufacturers constantly seek more innovative and efficient solutions due to increasing competition and ever-changing consumer expectations. At Sora Machine, we offer reliable and advanced cosmetic filling machines that meet all the needs of the cosmetics sector. Discover solutions with us that will enhance quality, speed, and flexibility in your production.

What Are the Challenges in Cosmetic Product Filling and How Should They Be Solved?

The formulations and packaging structures of cosmetic products vary. The choice of filling machine should be customized not only according to capacity but also to the type of product. So, which of your needs can be solved with Sora Machine?

1. How to Fill Liquid and Low Viscosity Products More Accurately?

For low viscosity products such as perfumes, tonics and essences, we work with perfume filling systems that ensure drip accuracy and prevent contamination. We offer various technologies such as magnetic, servo piston, and flow meter filling systems depending on the structure of your product.

2. How to Prevent Air Bubble Problems in Creams, Lotions, and High Viscosity Products?

With our vacuum-assisted filling systems and special nozzle designs, air bubble formation is minimized, and homogeneous filling is achieved in dense products such as creams, lotions, and masks.

3. How to Fill Aerosol Products Safely and Accurately?

Aerosol products such as hair sprays, deodorants, and sun sprays require sensitivity due to their pressurized structure. Sora Machine’s smart aerosol systems adapt to different valve and propellant types and provide safe, high-capacity filling.

4. What Should Be Considered for Filling Special Format Cosmetic Products?

For specially packaged products such as mascara, eyeliner, nail polish, and lip gloss, we design 100% customizable filling lines and offer solutions fully compatible with your brand’s packaging design.

How to Safely Fill Innovative and Sensitive Formulations?

Sora Machine’s advanced make up filling machines make a difference, especially for products with complex and sensitive contents:

-

How to Fill Microemulsions and Nanotechnological Products Without Deterioration?

Thanks to our sensitive filling mechanisms, products containing delicate particles and microemulsions are safely filled. -

How is Hygiene Ensured During the Filling Process of Organic and Natural Cosmetics?

With fully GMP-compliant, sterilizable, and contamination-preventing hygienic filling systems, your natural ingredients remain intact. -

How to Keep Multi-Phase (Two or Three-Phase) Products Stable?

For formulations like serum-oil mixtures, our specially designed filling lines maintain the structure of the phases during filling. -

How to Fill Foam and Pressurized Products Without Losing Foam Structure?

With our advanced aerosol systems, foam-based products are filled while preserving the formula and maintaining pressure balance.

How to Make Your Production Process More Efficient and Flexible?

At Sora Machine, we don’t just provide machines; we fully optimize your production line:

-

Which Production Model Should You Switch to With Full and Semi-Automatic Systems?

Whether you perform high-capacity or flexible small-scale productions, we provide the perfect balance of efficiency and speed with full or semi-automation options. -

How to Save Time During Product and Format Changeovers?

Thanks to the modular structure of our machines, you can switch quickly between different products and packages, shortening production times. -

How to Ensure That All Processes Work Harmoniously in Your Production Line?

Our filling machines can be fully integrated with systems such as capping, labeling, coding, and packaging. -

How to Continuously Improve By Collecting Production Data?

All our machines are equipped with advanced control and data collection systems. With continuous analysis and reporting, you can optimize your processes.

How to Elevate Hygiene and Quality Standards?

Hygiene is indispensable in the cosmetics industry. How do we design our filling systems at Sora Machine?

-

GMP Compliance: Our machines are manufactured fully in accordance with GMP standards.

-

Easy Cleaning and Sterilization: All product-contacting areas can be easily disassembled and sterilized.

-

Use of Hygienic Materials: The most reliable materials in the industry, such as 316L stainless steel, are used.

-

Closed System Design: During filling and transfer, the product does not come into contact with the external environment.

Why Should You Choose Sora Machine for Cosmetic Filling Machines?

You should choose Sora Machine for cosmetic filling machines for the following reasons:

-

Expertise specialized in the cosmetics industry

-

Wide range of products and machines

-

Superior quality, long-lasting systems

-

Customized solutions for your production

-

Comprehensive after-sales support

-

Innovative and continuously developing product portfolio

How to Reach Your Production Goals More Easily With Sora Machine?

-

Accelerate your production process

-

Improve your product quality

-

Reduce your costs

-

Increase consumer trust and brand value