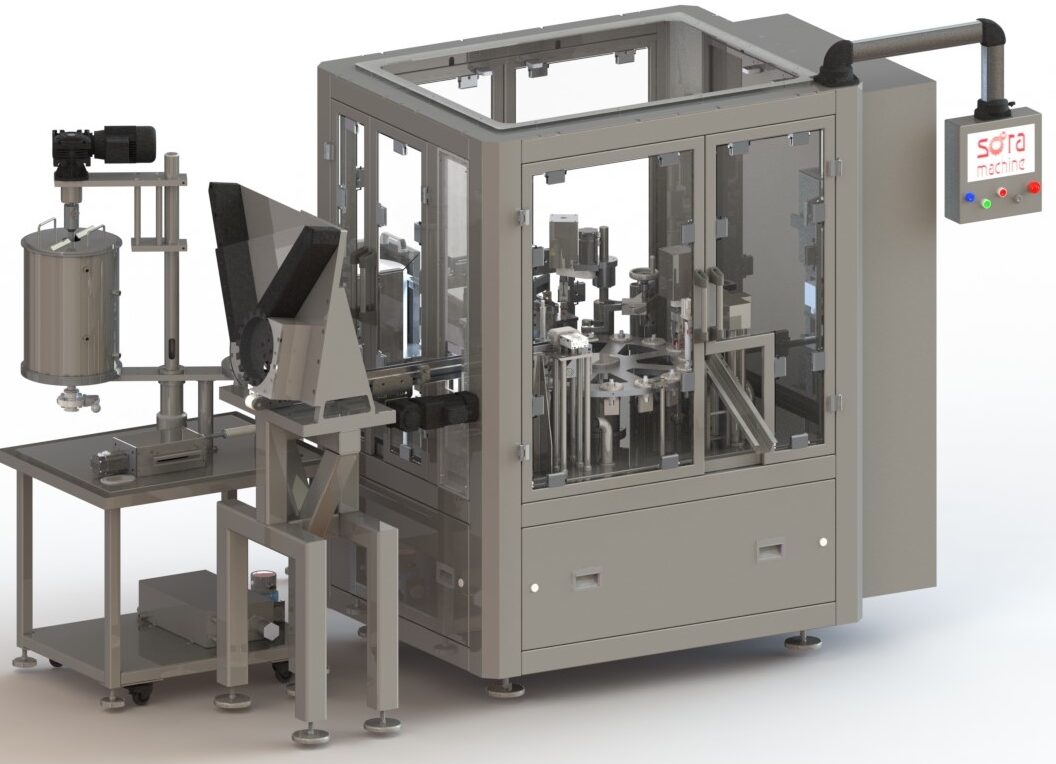

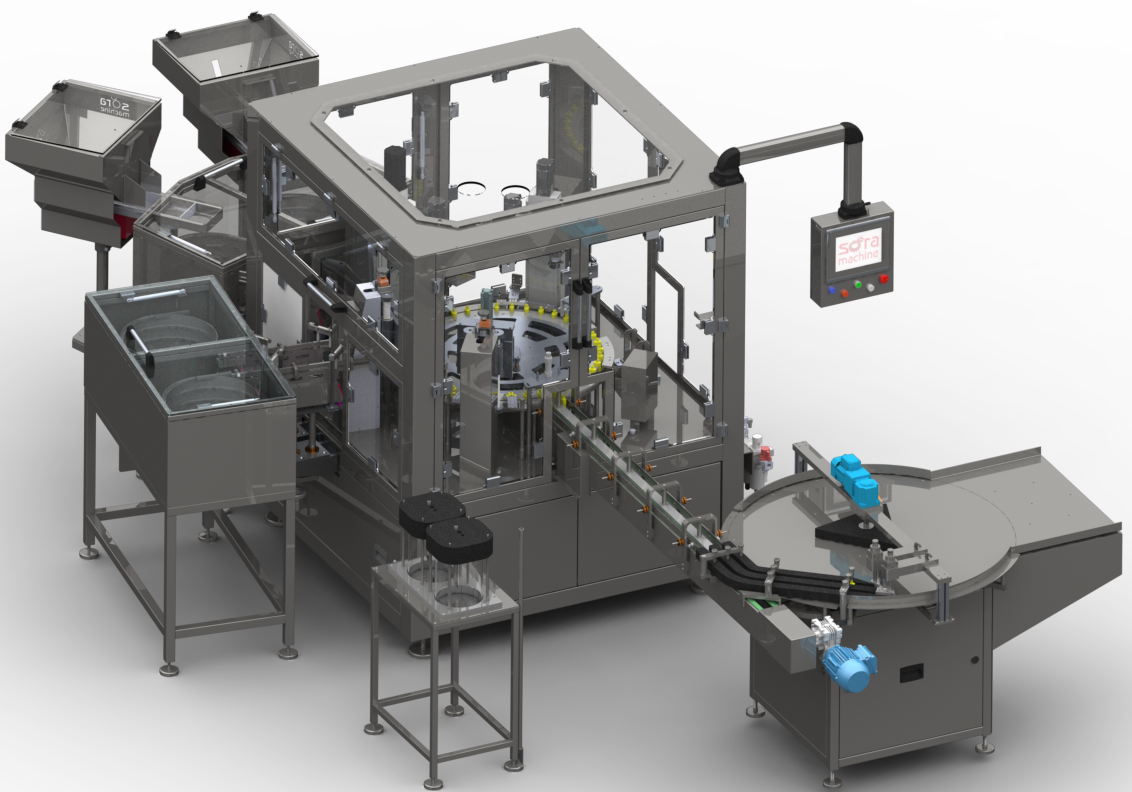

Make-Up Machines: Technological Power in Color Cosmetics Production

The mass production of products like foundation, lipstick, mascara, blush, and eyeshadow requires precise formulations, hygienic production environments, and high efficiency. Developed to meet these needs, Sora Machine makeup production machines offer specialized solutions for the modern cosmetics world.

Makeup machines are equipped with advanced features for the cosmetics production industry, such as high-precision dosing, homogeneous mixing, vacuum production, temperature-controlled processes, and automatic filling systems.

Challenges in the Production of Make-Up Products

Make up products are one of the most sensitive and innovative segments of the cosmetics industry. Products in this segment typically consist of:

- High viscosity (e.g., lipstick, cream blush)

- Sensitive formulations (balance of pigments, fragrances, active ingredients)

- High aesthetic quality expectations (color consistency, shine, texture)

Therefore, production processes must be carefully managed in terms of both chemical balance and mechanical precision. This is where Sora Machine makeup production systems offer manufacturers the ability to automate this entire process, stabilize quality, and increase efficiency.

Technical Specifications of Make-Up Machines

High-Precision Dosing

Even the smallest dosing error in makeup products can negatively affect product quality and aesthetic appearance. Sora Machine makeup production systems provide milliliter-level precision in every fill. This ensures that every product, regardless of packaging, is produced with the same volume and texture quality.

Vacuum Mixing and Homogenization

In many makeup products, the homogeneous mixing of pigments with the liquid base is critical. Thanks to mixing processes performed under vacuum:

- Air bubble formation is prevented

- Product shine and intensity are increased

- Shelf life is extended

Vacuum mixers are one of the most important processes for stabilizing high quality in products such as lipstick, foundation, BB cream, and liquid blush.

Temperature-Controlled Production

Especially in the production of lipstick, balm, and some cream-based products, temperature control is indispensable. Sora Machine’s temperature-controlled systems both protect the formula structure of the ingredients and ensure that the mixture remains at the perfect consistency.

Automatic and Semi-Automatic Filling

Cosmetic filling systems can be designed to suit various packaging types such as glass, plastic, and aluminum. Sora Machine machines can be developed with modules to support different processes such as:

- Liquid filling into lipstick molds

- Viscous cream filling into bottles and tubes

- Compacting processes for eyeshadow and blush

Product-Based Application Examples

Lip Glosses Filling Machines

Lip gloss filling machine systems for lipsticks, balms and lip glosses are offered, including vacuum melting tanks, mold filling lines and cooling tunnels.

Mascara Filling Machines

Sora Machine offers specialized mascara filling machines for various types of mascara, featuring precise filling nozzles, automatic brush insertion, viscosity control, and air bubble prevention. Optional fiber dosing units are also available for fiber mascaras.

Nail Polish Filling Machines

Sora Machine provides automated nail polish filling lines with accurate dosing pumps and anti-drip nozzles. These lines feature automated capping stations and level control sensors. Optional agitation systems are also offered for pigmented nail polishes.

Flexibility in Production and Customizable Systems

Sora Machine makeup machines can be adapted to different formulas and packaging types. Depending on the customer’s production capacity, product type, and packaging format, options such as:

- Manual, semi-automatic, or fully automatic lines

- Multi-head filling systems

- Integrated labeling, capping, and quality control modules

can be offered. This structure provides the manufacturer with flexible production capabilities while also increasing the scalability of the investment.

Safe and Efficient Solution in Cosmetics Production

In the production of makeup products, not only speed but also safety, compliance with standards, and product quality are at the forefront. Sora Machine provides operational superiority to manufacturers by considering factors such as:

- Design in accordance with GMP and ISO standards

- Easy-to-clean process surfaces (with CIP option)

- Low energy consumption

- Fast product changeover and easy recipe management in all its systems.

Why Sora Machine Make-Up Production Systems?

- Long-lasting, high-quality material usage

- Domestic production and global market experience

- Project-based engineering support

- Technical service, spare parts, and training services

- Ease of integration with automation infrastructure

Sora Machine offers not only machines but also holistic production solutions. Whether you are setting up a new production line or upgrading your existing system, you can take your production to the next level with our makeup machines.

Be Prepared for the Future of Cosmetics Production Today

In the highly competitive cosmetics industry, making a difference is possible not only with quality formulas but also by producing these formulas flawlessly and efficiently. Sora Machine Make-Up Machines are the ideal solution for all manufacturers who want to turn this vision into reality.