The journey toward sustainability in the aerosol industry is gaining momentum as consumers and regulatory bodies become increasingly environmentally conscious. But how does this green revolution begin? The answer largely lies in aerosol production machines. The development of an eco-friendly aerosol product is made possible through the use of the right equipment and technologies.

How Are Eco-Friendly Aerosols Produced? Which Propellants and Aerosol Filling Machines Are Used?

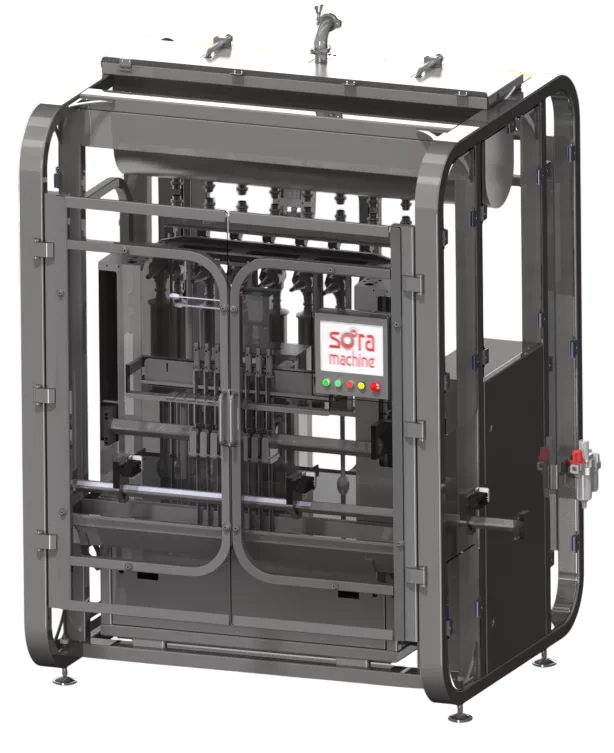

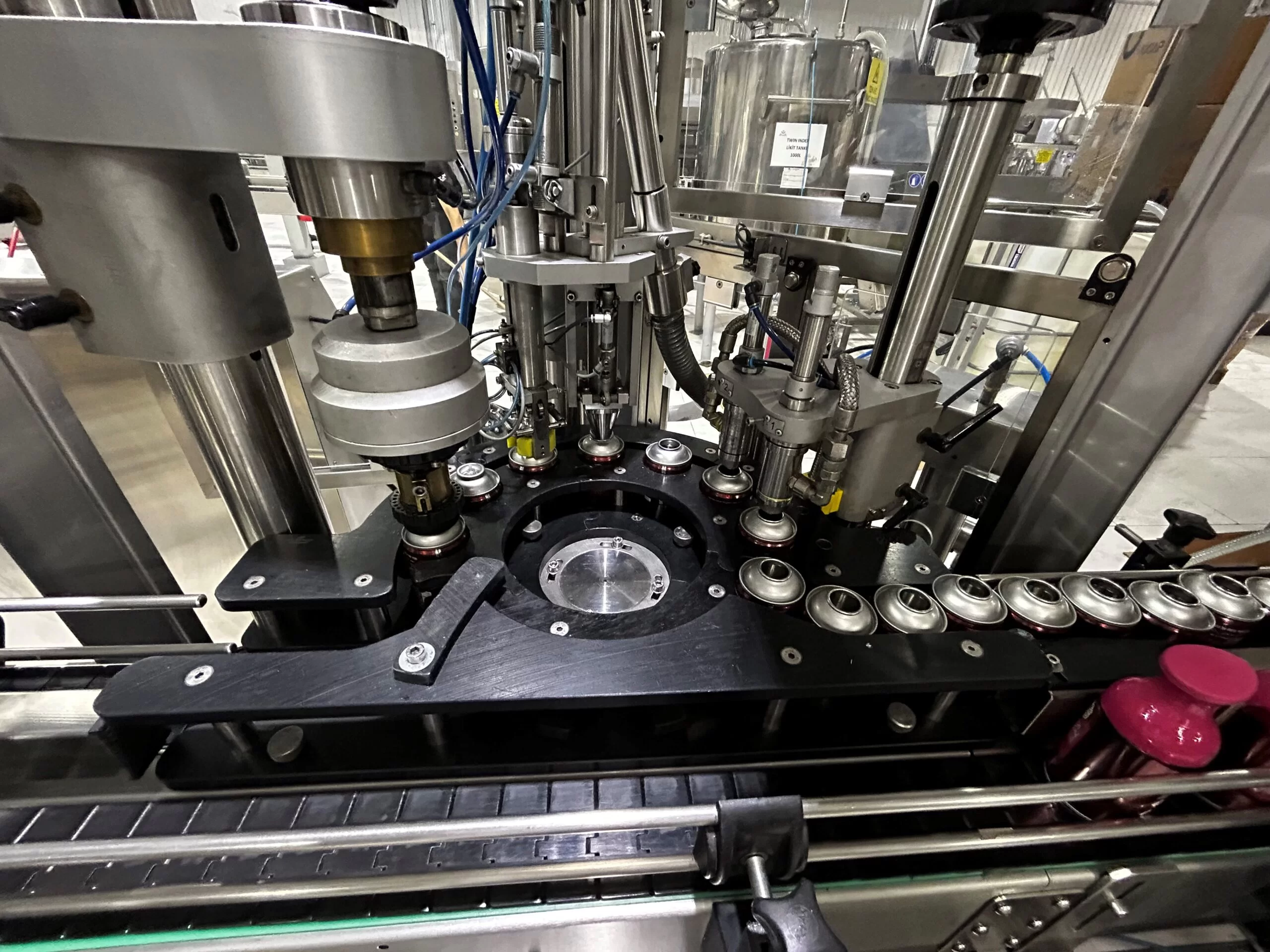

The production of eco-friendly aerosols requires different approaches compared to traditional methods. The first step is selecting propellants that are less harmful to the environment. Alternatives such as compressed air, nitrogen, carbon dioxide (CO2), and dimethyl ether (DME) stand out as options that do not harm the ozone layer and reduce greenhouse gas emissions. Bio-based propellants are also gaining increasing interest. The use of these propellants necessitates certain adaptations in aerosol filling machines. Specially designed aerosol filling machines that can precisely fill these gases, which have different pressure and viscosity requirements, are crucial for sustainable production.

Why Are Eco-Friendly Aerosol Products Preferred? Consumer Expectations

Today, consumers not only expect the products they purchase to be functional but also to have minimal environmental impact. Sustainability has become a key purchasing criterion. In various sectors such as cosmetics, home care, food, and industrial products, the demand for eco-friendly aerosol products is steadily increasing. Consumers expect brands to adopt environmentally conscious practices and offer products aligned with this vision. Therefore, transitioning to eco-friendly products is both an ethical responsibility and a significant market advantage for aerosol manufacturers.

What Challenges Are Faced in Eco-Friendly Aerosol Production? Solutions from Aerosol Filling Machines

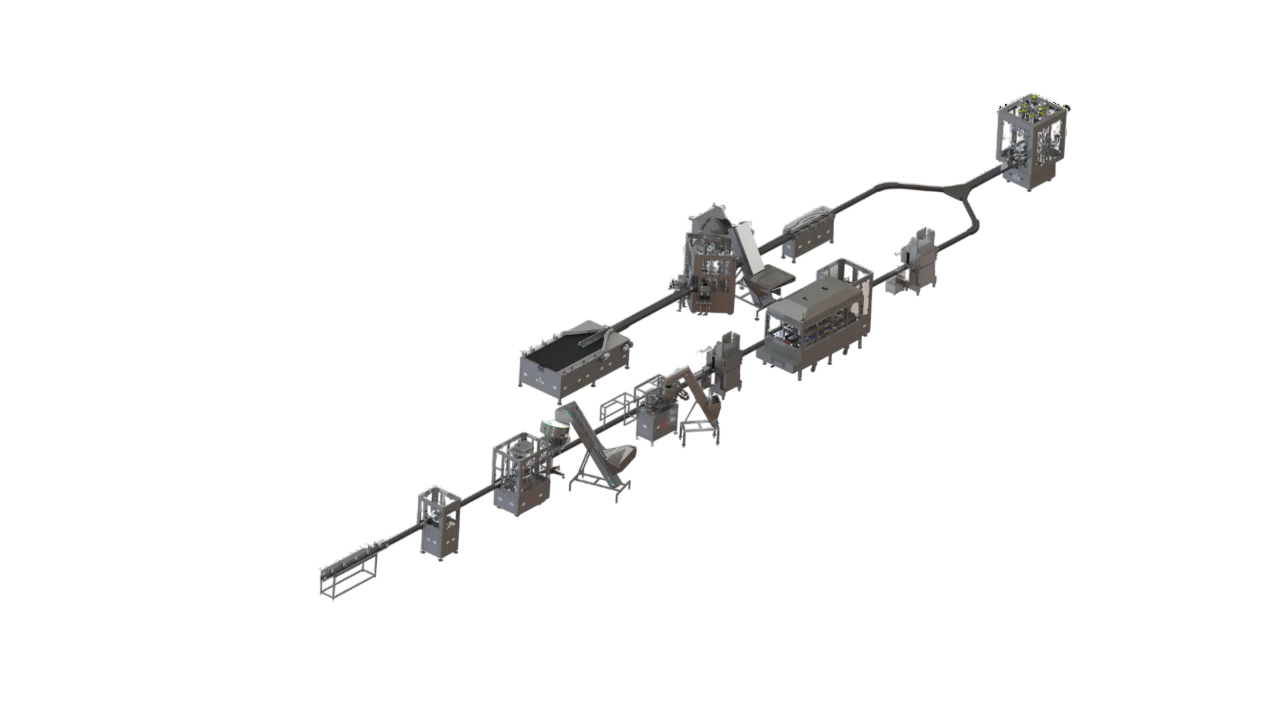

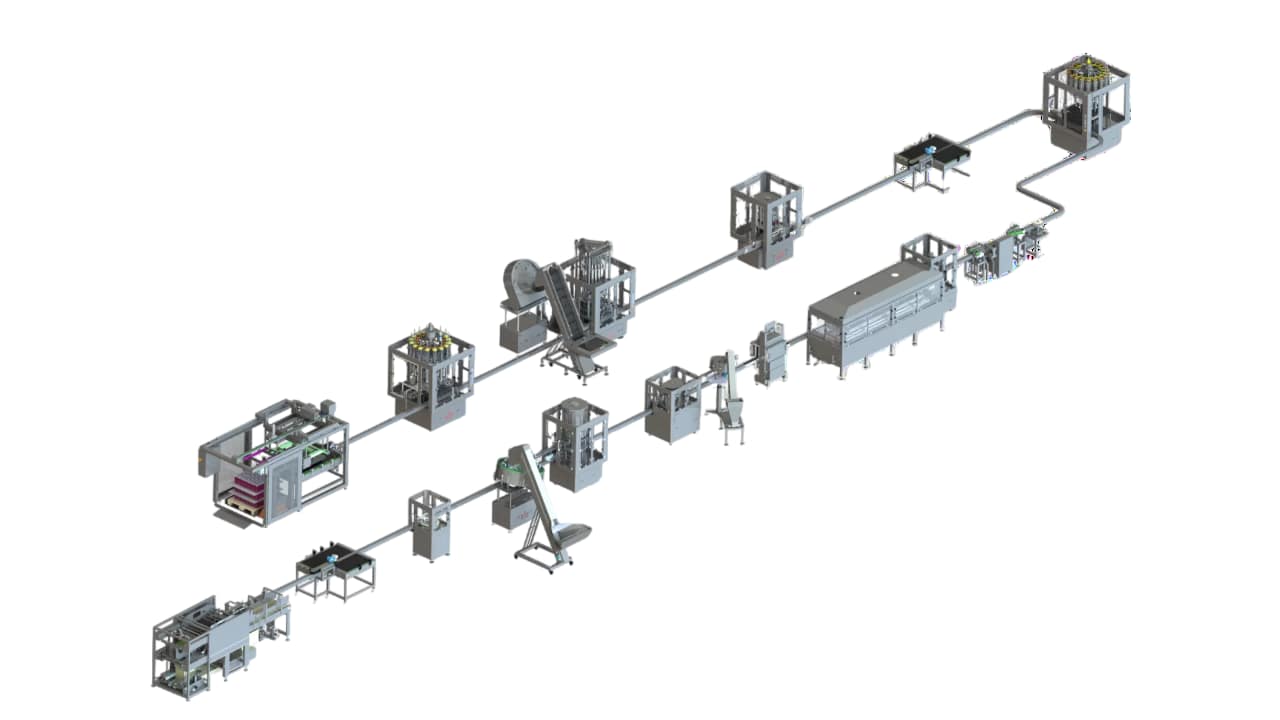

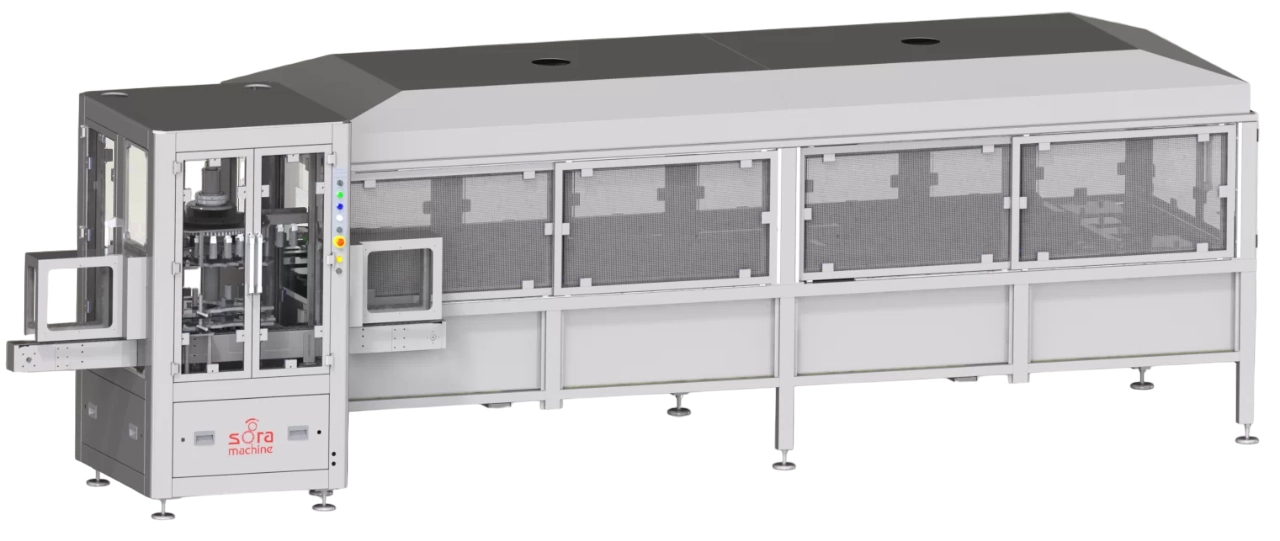

The transition to eco-friendly aerosol production can present certain technical and operational challenges. Factors such as the compatibility of alternative propellants with formulations, the adaptation of existing aerosol filling machines to these new gases, product stability, and shelf life must be carefully considered. Fortunately, recent advancements in aerosol filling machine technologies offer various solutions to overcome these challenges. Modern machines are equipped with features that enable precise processing of different propellant types, enhance energy efficiency, and minimize waste production.

Which Aerosol Filling Machines Are Needed for Eco-Friendly Aerosol Production?

For manufacturers looking to meet the growing demand for eco-friendly aerosol products, choosing the right aerosol filling machines is critical. Machines specifically designed for different types of propellants ensure that production processes are carried out efficiently and safely. Additionally, energy-efficient aerosol production machines with low waste output play a vital role in achieving sustainability goals. New-generation aerosol filling machines often have flexible structures that allow them to adapt easily to different product and packaging types.

What Are the Green Packaging Solutions for Aerosol Products?

The sustainability of an eco-friendly aerosol product is not limited to its contents; packaging is also a key part of the equation. Recycled aluminum and plastics (PCR), biodegradable materials, and designs aimed at reducing packaging weight are among the increasingly preferred green packaging solutions for aerosol products. It is essential that aerosol production machines are compatible with these new-generation packaging materials to ensure smooth production processes.

How Are Eco-Friendly Aerosol Products Marketed?

Delivering eco-friendly aerosol products to consumers and communicating their value requires a well-crafted marketing strategy. The environmental benefits of these products should be clearly stated on packaging and promotional materials. Green certifications and labels can effectively build consumer trust. Additionally, maintaining transparent communication about sustainable production processes and the materials used can strengthen brand image.

What Does the Future of Aerosol Production Look Like? Greener and More Efficient Machines

The trend toward sustainability in aerosol production will continue to grow in the future. Research and development efforts in the industry focus on developing aerosol production machines that consume less energy, produce minimal waste, and are made entirely from recyclable materials. Smart sensors, AI-supported control systems, and automation technologies will play a crucial role in making production processes more efficient and environmentally friendly.

Why Is Investing in Eco-Friendly Aerosol Product Machines Important?

The demand for eco-friendly aerosol products is steadily increasing, presenting a significant market opportunity for aerosol manufacturers. Adopting environmentally friendly production processes and investing in the right aerosol product machines will not only provide businesses with a competitive advantage but also contribute to a more sustainable future. Companies that keep up with this transformation and invest in green production technologies will secure a strong position in the future aerosol market.