The pharmaceutical industry is a field that directly affects human health and requires an extremely sensitive production process. Producing drugs in the correct dose, safely, and effectively is critical for treatment success. In this article, we will explore why special production systems such as MDI filling machines and aerosol filling machines form a separate category, what needs these machines meet, and how the right choices can make a difference.

What is an MDI Filling Machine and Why is it Important?

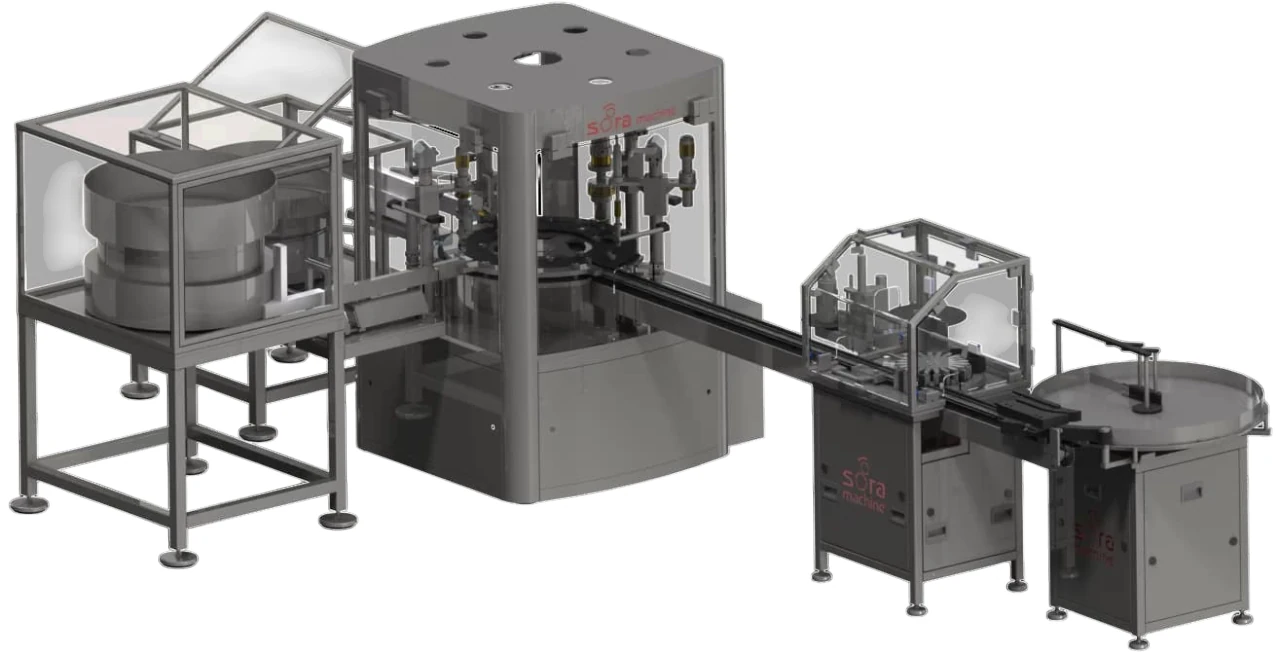

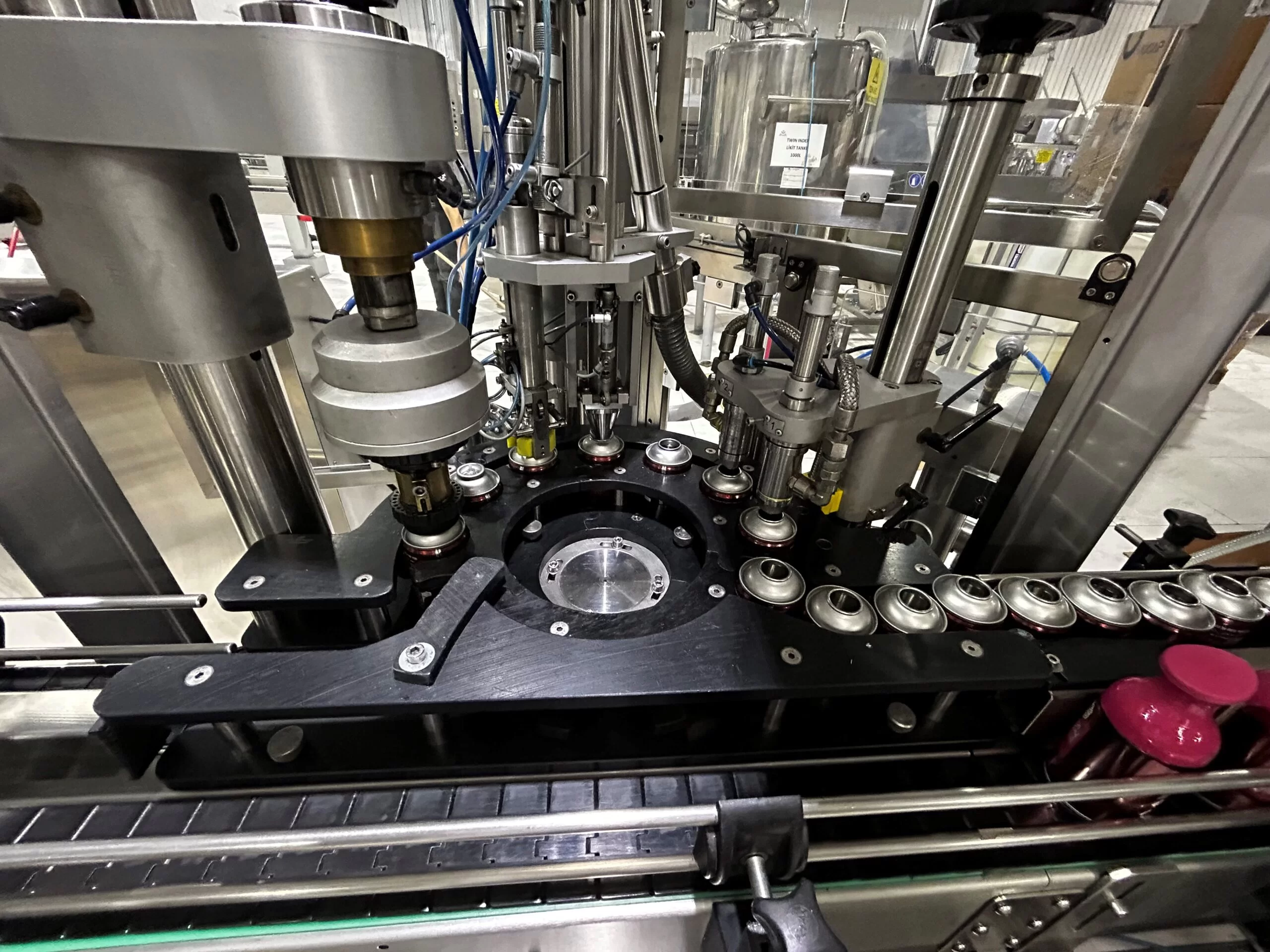

MDI (Metered Dose Inhaler) is a drug delivery system used especially in the treatment of respiratory diseases such as asthma and COPD. These devices are aerosol devices that allow a specific dose of medication to be inhaled with each breath. MDI filling machines are special machines used in the production of these products and ensure that the dosage is adjusted with extreme precision. This is because the effectiveness of MDI products is based on delivering the correct dosage.

MDI filling machines not only provide the dosage precision required for respiratory medications but also guarantee the sealing properties of each device. These machines ensure that the medication is produced in the correct amount and safely, so patients get the highest efficiency in their treatment process.

Aerosol Filling Machines: Why is This Technology Preferred?

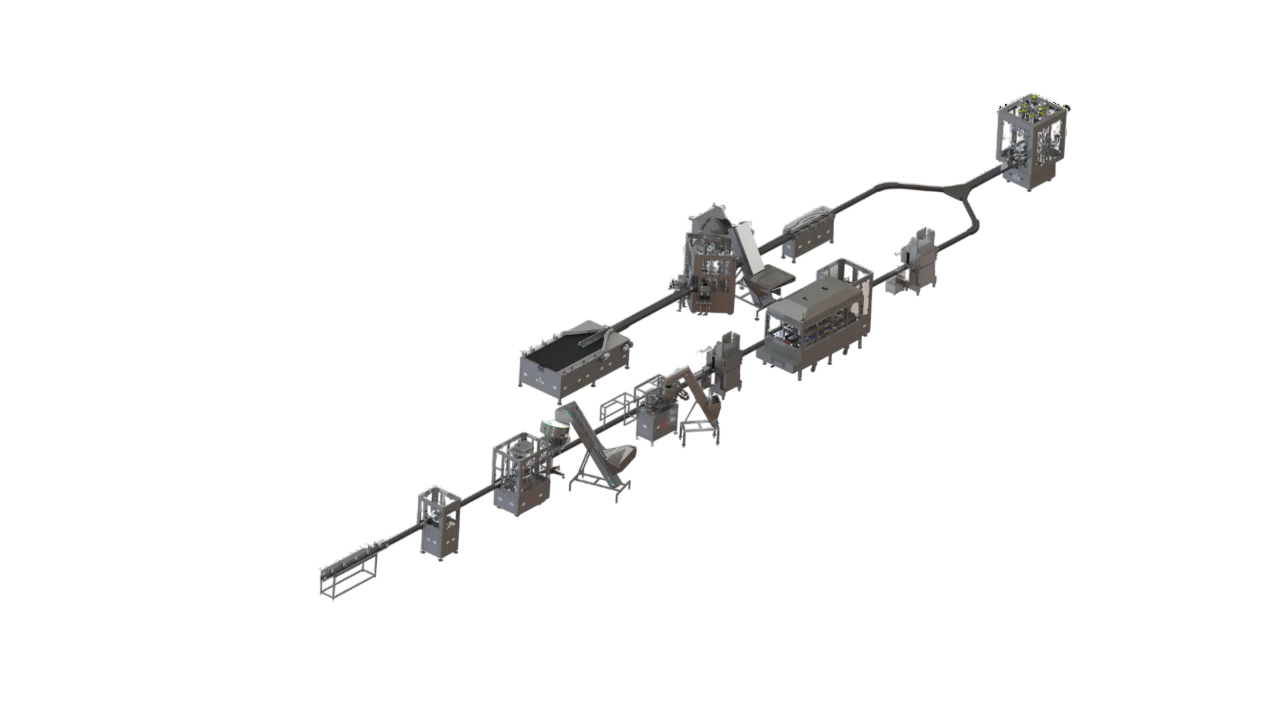

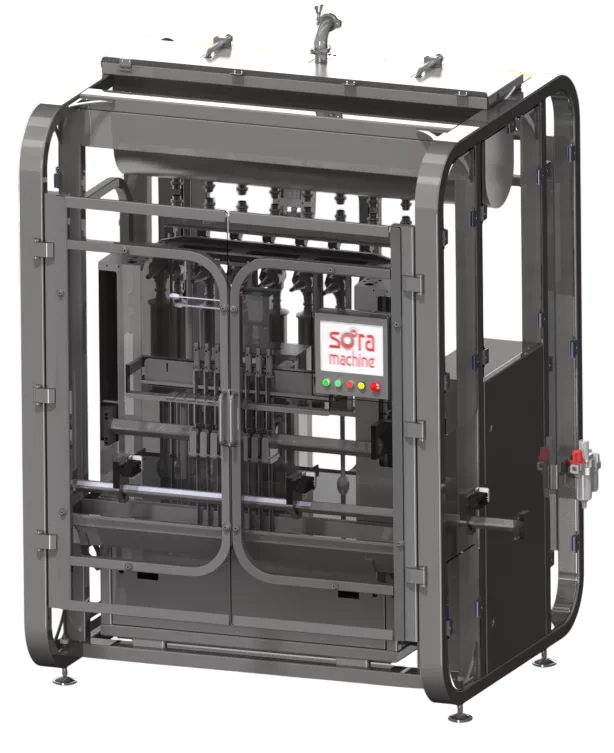

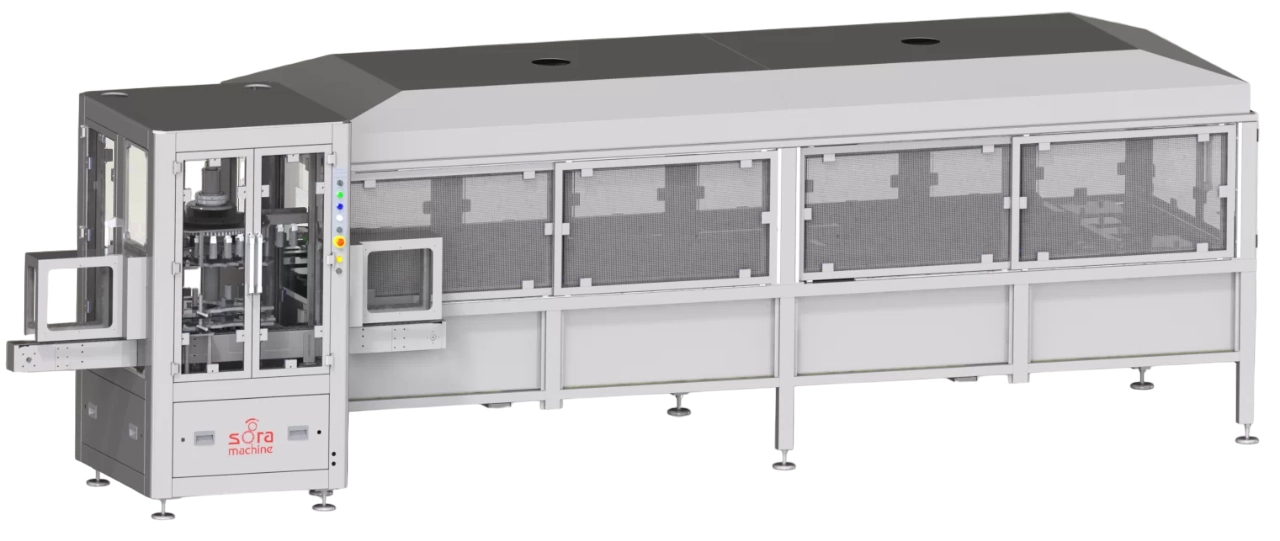

Aerosol filling machines are indispensable in the production of spray medications, antiseptic sprays, nasal sprays, and inhaler products. These machines fill liquid medication and propellant gas (usually a propellant) in perfect balance, ensuring production at the correct dosage and safely. Thanks to aerosol filling machines, each spray contains the correct amount of medication, which increases treatment effectiveness and makes it easier for patients to adhere to their treatment.

For an aerosol filling machine to work correctly, both components – the medication and the gas – must be mixed precisely. Being able to make dosage adjustments at the micron level is a critical factor for the efficacy and safety of medications.

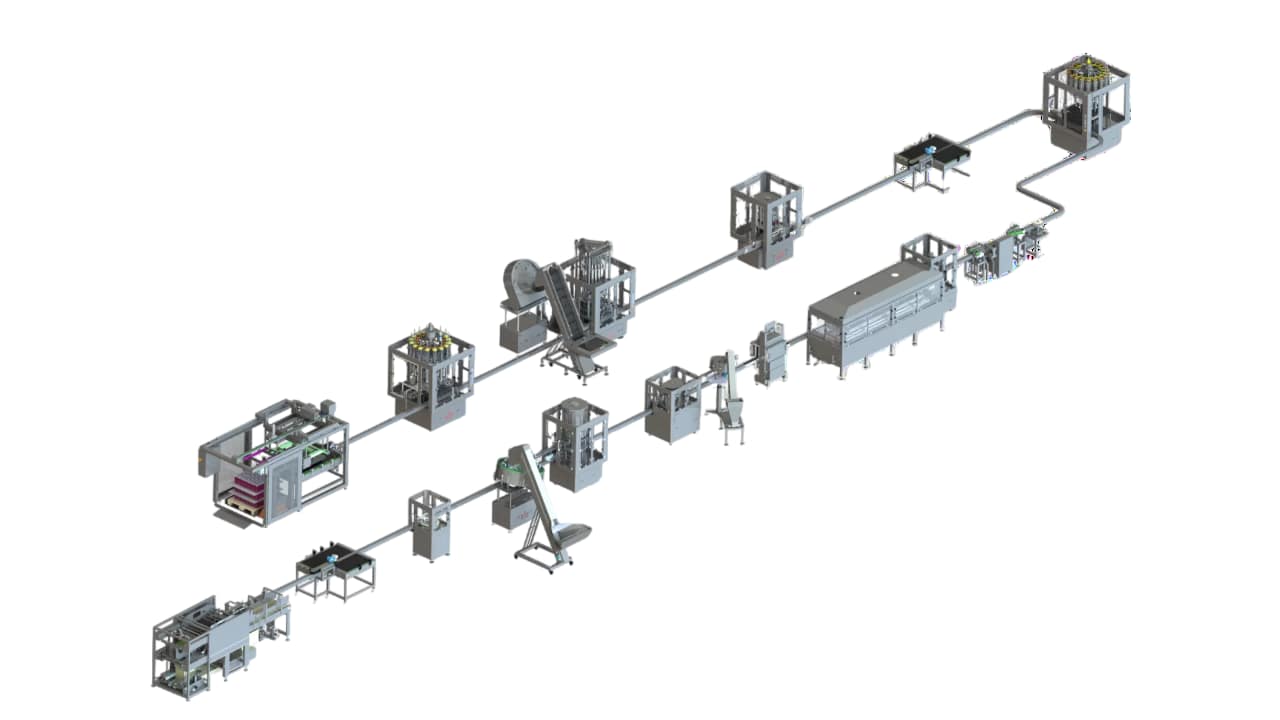

MDI and Aerosol Filling Machines: What Products Are Produced with These Systems?

MDI and aerosol filling machines are used in the production of a wide variety of pharmaceutical and medical products. These machines are specifically designed for spray medications, nasal sprays, aerosol-based medications, and inhaler products. These types of products are taken directly through the respiratory tract and have a rapid effect. Here are some products produced with these machines:

- Medical sprays: Antiseptic, nasal spray, wound sprays

- Aerosol-based medications: Inhaler medications used in the treatment of asthma and COPD

- Sterile solutions: Skin antiseptics and other sterile products

- Skincare products: Dermo-cosmetic sprays

Since each product requires dosage control with high accuracy, special systems such as aerosol filling machines and MDI filling machines are used.

MDI Filling Machine Selection: What Features and Technologies Should Be Looked For?

The most important features to consider when choosing MDI filling machines should be dosage accuracy, sealing, and sterile production. These machines play a critical role, especially in the production of inhalers used in asthma treatment. Dosage errors can lead to patients not adhering to treatment or can pose a health hazard. Therefore, the dosage must be measured correctly, and the sealing of each inhaler must be guaranteed.

Dosage Accuracy

MDI filling machines have the ability to make dosage adjustments at the micron level. Each puff should contain the correct amount of medication, and the patient should receive exactly the correct dosage. This directly affects the effectiveness of the treatment process.

Sealing and Safety

Sealing is very important for MDI products to maintain their effectiveness. It must be ensured that the medication is placed correctly, the propellant gas does not leak, and the device always operates safely.

Things to Consider Regarding Aerosol Filling Machines

Aerosol filling machines hold an important place, especially in the production of medical and cosmetic products. These machines not only ensure that medications are filled at the correct dosage but also provide sterility and eliminate the risk of contamination. The biggest advantage of aerosol filling machines is that, thanks to the complete isolation of the product and gas, medications do not come into contact with air, thus preserving sterility conditions.

MDI and Aerosol Filling Machines: Which Choices Will Make You Safer and More Efficient?

Choosing the right machine in the pharmaceutical production process is critical not only for production efficiency but also for safety, regulatory compliance, and protecting your brand reputation. Choosing the wrong machine can lead to production errors, product recalls, and high costs. With the right technologies like MDI filling machines and aerosol filling machines, you can produce your products with high accuracy, sterility, and safety.

The right choices both optimize production processes and reduce your costs, increasing your competitiveness. Remember, producing with the right machines makes a critical difference not only in terms of efficiency but also in terms of patient safety and treatment effectiveness.