Packaging and Palletizing Solutions and Systems Adding Value to Post-Production Processes

Every product leaving the production line embarks on a journey that directly affects the brand’s prestige and customer satisfaction. Ensuring this journey is safe, efficient, and cost-effective depends on well-designed packaging and palletizing solutions. Modern systems used in post-production processes optimize the logistics flow, providing businesses with a competitive advantage.

Thanks to innovative and highly efficient machines developed for companies operating in various sectors such as food, industry, retail, and logistics, post-production operations are carried out more safely, quickly, and economically.

What are the Solution and System Types with Post-Production Packaging Machines?

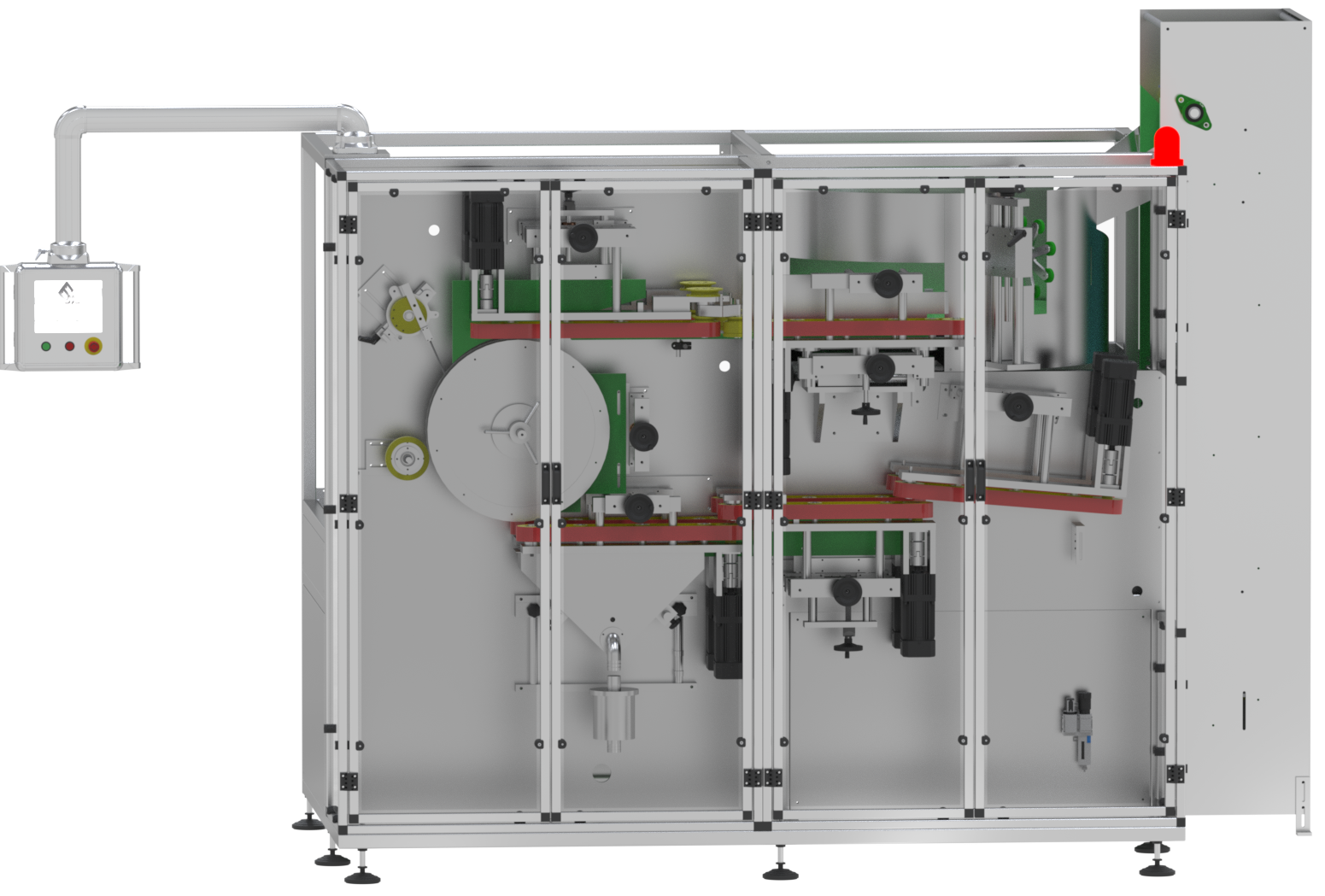

What are Cardboard Box Packaging Machine Systems?

Automatic and semi-automatic machines that ensure products are placed safely, regularly, and aesthetically into cardboard boxes.

- Automatic box forming, placing, and closing

- Adaptation to different box sizes and shapes

- High speed, low error rate, and labor savings

What are Shrink Packaging Machine Systems?

Ensures products are protected by being wrapped in transparent and durable film, making them appear more attractive on shelves.

- Suitable for single and multiple product groups

- Extends product shelf life and offers ease of transportation

- Aesthetic and robust packaging

What are Robotic Palletizing Machine Systems?

Ensures packaged products are placed onto pallets quickly, precisely, and flexibly.

- Different palletizing patterns and programmable structure

- Fully integrated into the production line, high-speed solutions

- Flexible and reliable automation

What are Layer Palletizing Machine Systems?

Ensures heavy and bulky products are palletized stably and balanced.

- Maximum load balance with layered arrangement

- Space efficiency during storage and transportation

- Up to 20% space saving

What are Integrated Packaging and Palletizing Machines and Lines?

Optimizes the production flow by combining packaging and palletizing machine operations on a single fully automatic line.

- Fully integrated structure from production to shipment

- Continuous and high-speed production

- Minimum human intervention, maximum efficiency

Which Sectors are Packaging Machines Suitable For?

These packaging machines can be easily adapted to many different sectors and production dynamics:

| Sector | Application Areas |

| Food and Beverage | Biscuits, chocolate, beverages, dairy products, canned goods, etc. |

| Industry | Automotive, plastics, electronics, metal parts |

| Retail | Cleaning, cosmetics, toys, stationery, FMCG products |

| Logistics | Distribution centers, warehouses, e-commerce logistics |

What are the Advantages of Packaging Machines in Post-Production Processes?

- Increase in Production Efficiency: Production capacity increases with fast and continuously operating machines.

- Consistent and High Quality: Ensures products are packaged with the same quality and precision every time.

- Labor Optimization: Labor savings are achieved through automation, and human resources are used more effectively.

- Flexible Production Opportunity: Offers flexible production possibilities with machines that easily adapt to different product sizes and shapes.

- Logistics and Storage Advantage: Savings in transportation and storage costs are achieved thanks to regular and balanced palletizing.