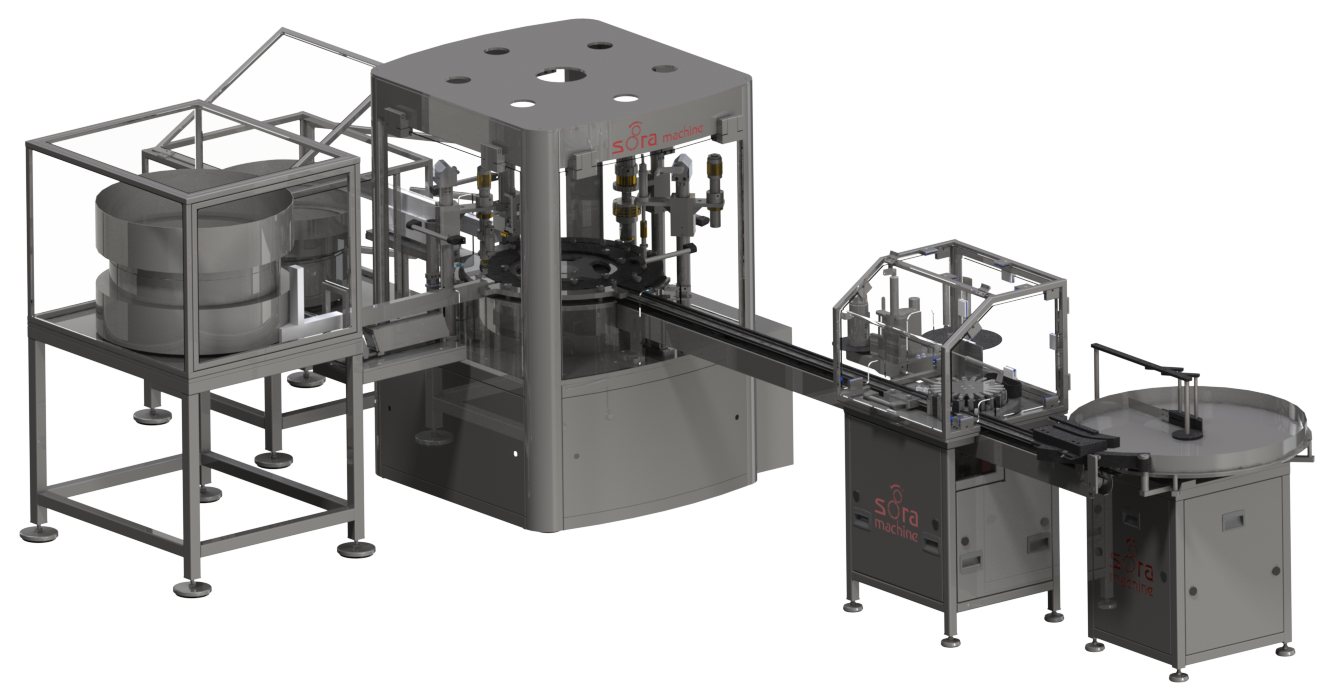

Aerosol, Filling, and Production Line Machines in Pharmaceuticals and Medical Products: Why Are They Vital?

Production in the pharmaceutical sector is not just a filling process; it’s a high-precision operation with zero tolerance for error, directly impacting human health. So, why are the machines used in pharmaceutical filling, capping, aerosol production, and inhaler systems so critical? Which machines offer solutions to which needs? And most importantly, why is choosing the right machine not only crucial for production but also for safety, regulatory compliance, and brand reputation?

Why Are Specialized Production Lines Needed in Pharmaceutical Manufacturing?

Pharmaceutical and medical products are products that come into direct contact with the human body or are inhaled. Therefore, elements such as sterilization, dosage accuracy, and leak control must function flawlessly at every stage of the production lines. Ordinary filling systems are not sufficient for pharmaceuticals and medical products. It is mandatory that every machine used in the production line complies with international quality, hygiene, and safety standards. The machines commonly used in the pharmaceutical industry stand out in the following categories:

- Aerosol Filling Machines

- Inhaler (MDI) Production Lines

- B.O.V (Bag on Valve) Systems

- Fully Automatic and Semi-Automatic Filling Machines

- Leak Testing Devices and Checkweigher Systems

Why Are Aerosol Filling Machines Important?

Spray medications, nasal sprays, antiseptic sprays, and medical aerosol products are produced precisely with aerosol filling machines. These machines perform the filling of both the liquid and the propellant (driving gas) with a precise balance. Micron-level dosage adjustments can be made during production, which is a critical requirement for treatment effectiveness.

Why Is the MDI (Metered Dose Inhaler) Filling Machine a Separate Category?

Inhaler products used in the treatment of respiratory diseases such as asthma and COPD cannot be produced on an ordinary filling machine. Consistent and accurate dosage, the necessity of milligram-based dosing, and ensuring the airtightness of the inhaler system are mandatory. For this reason, MDI filling machines are equipped with high-capacity, controlled, and GMP-compliant special systems.

Why Is B.O.V (Bag on Valve) Technology Preferred?

Bag on Valve (B.O.V.) technology provides hygienic filling and safe product presentation in aerosol filling. Thanks to this system, where the product and gas are completely isolated from each other, the drug or medical liquid does not directly contact the air, and the risk of contamination is eliminated. B.O.V. systems are indispensable, especially in medical and pharmaceutical products where sterility is paramount.

Why Should Pharmaceutical Production Lines Be Suitable for Full Automation?

One of the most fundamental questions for many manufacturers is: Should I prefer fully automatic or semi-automatic?

The answer to this question varies depending on production volume, product diversity, and target markets. However, especially in pharmaceuticals and medical products, fully automated systems both minimize human error and make it easier to comply with international standards such as GMP and ISO. Throughout the production process:

- From product feeding to filling,

- From cap closing to leak testing,

- From weighing to labeling and packaging,

it is a legal requirement that all stages are controlled and traceable.

Why Are Leak Testing and Checkweigher Systems Indispensable?

The production of a drug or medical product does not end after filling. The most critical stage is quality control. Leak testing devices check the safety of pressurized products such as aerosols and inhalers, while checkweigher systems automatically check whether the filling weight of each product is within tolerance. Thanks to these controls, both consumer safety is ensured, and costly and risky situations such as recalls are prevented.

Which Product Groups Are Produced with These Systems?

The main products produced with these machines are:

- Medical sprays (antiseptic, nasal spray, wound sprays)

- Inhaler products used by inhalation

- OTC (over-the-counter) spray and topical products

- Sterile solutions

- Skin care and dermo-cosmetic products

- Aerosol sprays in drug form

Why Is Choosing the Right Machine Strategic in Pharmaceutical Manufacturing?

Many manufacturers focus only on the price of the machine when setting up their production system. However, the crucial question is: “Which machine will guarantee quality, continuity, and regulatory compliance in the long run?”

A low-quality or incompatible machine can not only lead to production problems but can also result in the recall of products placed on the market, damage to brand reputation, and high costs. With the right system selection, production processes are optimized, costs are reduced, and competitiveness increases.

Excellence in Pharmaceutical Manufacturing is Possible with the Right Production Lines

In the pharmaceutical and medical fields, machines are not just equipment; they directly signify quality, safety, and reliability. A well-planned and correctly chosen production line will not only take you to your production target but also to becoming a world-class brand. Therefore, in the selection of filling, capping, testing, and packaging machines, it is essential to consider the steps of precision, hygiene, full automation, and quality control.