How Can You Increase Your Power in the Aerosol Industry? What are the Right Filling Solutions?

Aerosol products, which we encounter in many different sectors today, have become an indispensable part of our lives thanks to their practical use and effective results. These products, ranging from personal care to industrial use, play a critical role in production with aerosol filling machines that offer high precision and reliability. Whether you operate in the cosmetics, pharmaceutical, food, or industrial sector, the right filling technology is vital for your business success. In this category, we offer comprehensive information to help you find the most suitable aerosol filling machine for your needs.

What Kind of Aerosol Filling Solutions Does Sora Machine Offer?

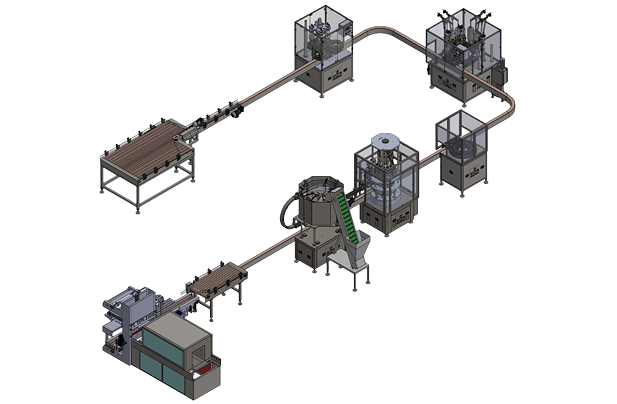

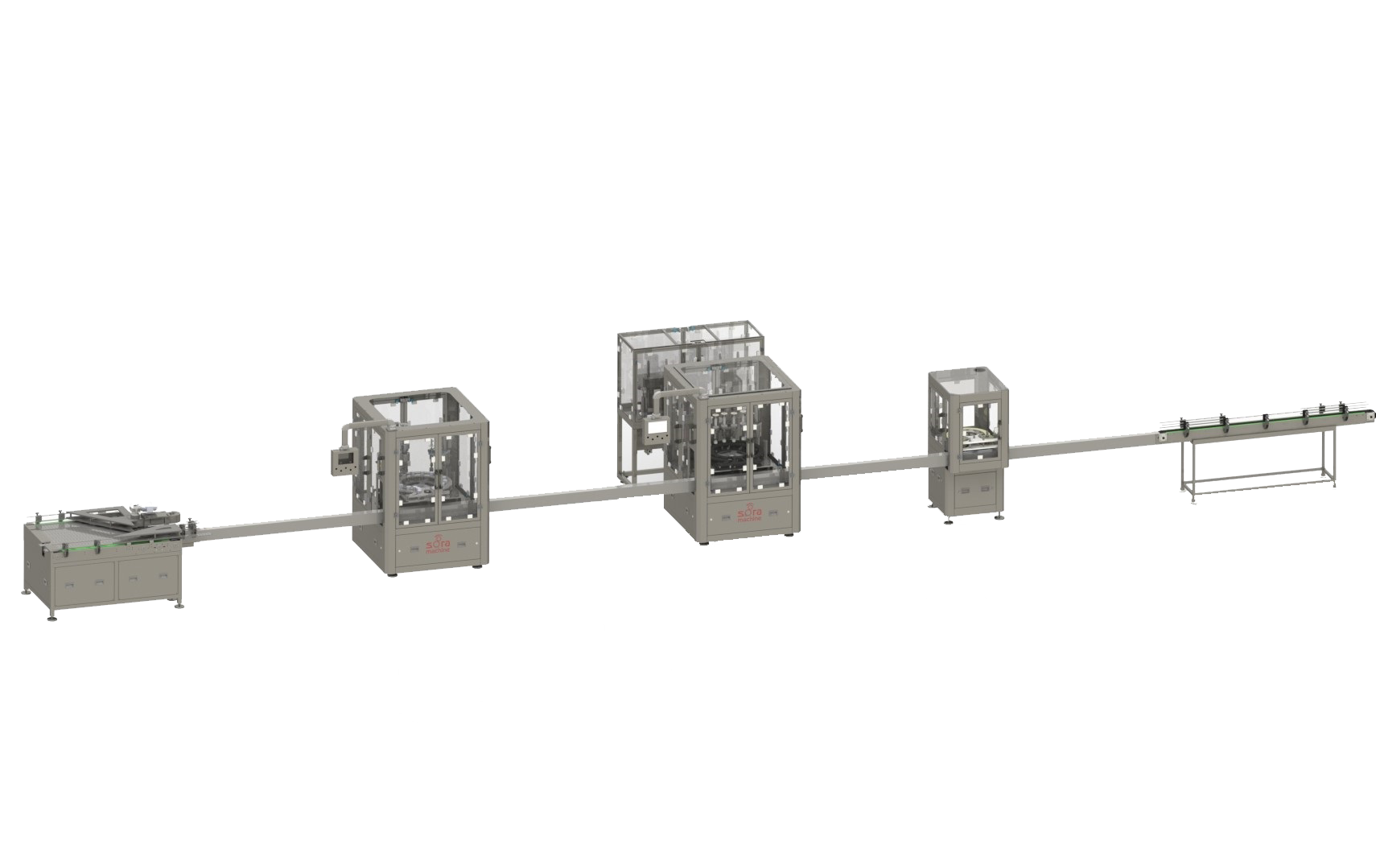

Aerosol filling machines offered by leading manufacturers in the sector, such as Sora Machine, are designed to meet different production needs. These machines help you optimize your production processes by accurately and efficiently filling liquid or gaseous substances into aerosol cans.

What are the Basic Functions of Aerosol Filling Machines and How Do They Work?

Aerosol filling machines generally operate through a process consisting of several basic stages. First, empty aerosol cans are fed into the machine. Then, the product (liquid or concentrate) is filled into the can in the correct amount through filling nozzles. In the next stage, the valve placing unit places the valve on the can opening and tightly seals it. Finally, propellant gas (usually propane, butane, DME, or compressed gases) is injected into the can through a special system. This propellant gas allows the product to be sprayed out when the user presses the button.

What Types of Aerosol Filling Machines are Available for Different Production Needs?

Aerosol filling machines offered by Sora Machine and other manufacturers vary according to different production volumes and application areas. The main machine types are as follows:

- Are Semi-Automatic Aerosol Filling Machines Suitable for Lower Production Volumes? Yes, semi-automatic aerosol filling machines are ideal for lower production volumes. These machines require the operator to perform some operations manually and are generally a cost-effective option for startups or small-scale production businesses. They offer flexibility for filling various aerosol products.

- What Advantages Do Fully Automatic Aerosol Filling Machines Offer for High-Speed and Continuous Production? Fully automatic aerosol filling machines are designed for high-speed and continuous production. These machines perform all filling operations automatically and are ideal for large-scale production facilities. They provide high efficiency, and models compatible with different viscosity products and various aerosol can types are available.

- Why Should Rotary Type Aerosol Filling Machines Be Preferred for High-Speed Production Lines? Rotary type aerosol filling machines are preferred for high-speed production lines because they have multiple filling stations on a rotating platform. This allows different filling operations to be performed simultaneously, which significantly increases the production speed.

- What are Linear Type Aerosol Filling Machines That Can Adapt to Different Production Requirements? Linear type aerosol filling machines perform filling operations on a sequential line and may have modular designs that can adapt to different production requirements. They offer suitable options for medium and high-volume production.

- Should I Choose a Single-Station or Multi-Station Aerosol Filling Machine According to My Needs? You can choose a single-station or multi-station aerosol filling machine according to your needs. Single-station machines are suitable for simpler applications, while multi-station machines allow different products or different stages to be carried out simultaneously, which is ideal for more complex production processes.

In Which Sectors and For Filling What Types of Products Are Aerosol Filling Machines Used?

The usage areas of aerosol filling machines are quite wide, and machines from Sora Machine and other manufacturers are suitable for filling many different products such as: Cosmetics and Personal Care Products (deodorants, hair sprays, body sprays, sunscreens, shaving foams, perfumes), Household Care Products (air fresheners, surface cleaners, furniture polishes, insecticides), Automotive Products (spray paints, car care sprays, tire repair sprays), Industrial Products (lubricants, rust removers, adhesives, mold release agents), Pharmaceutical and Health Products (nasal sprays, antiseptic sprays, wound care sprays), Food Products (cooking oil sprays, whipped cream sprays), Agricultural Products (plant protection sprays).

What Should I Pay Attention to When Choosing the Right Aerosol Filling Machine?

Choosing the right aerosol filling machine for your business is a critical step for your long-term success. It is important to consider the following factors when making a selection:

- What Should My Production Volume and Speed Requirements Be? The production volume and speed your business needs will directly affect the type and capacity of the machine you choose. Fully automatic machines are more suitable for high-volume production, while semi-automatic machines may be sufficient for low-volume production.

- How Do the Properties of the Product I Will Fill Affect the Machine Selection? The viscosity, foaming property, flammability, and other properties of the product to be filled will affect the material selection and filling technology of the machine.

- Which Machine Does the Aerosol Can and Valve Type I Will Use Require? There are suitable machines for aerosol cans of different sizes and materials and different valve types. It is important to choose a machine with a filling and closing mechanism suitable for the can and valve type you will use.

- How Much Automation Do I Need in My Production Process? You should choose a machine with the appropriate level of automation based on your budget, labor costs, and production targets.

- Why Should Hygiene and Safety Standards Be Important to Me? Especially for the pharmaceutical and food industries, machines that comply with hygiene standards and provide a safe working environment should be preferred.

- What Size Machines Are Suitable for the Installation Area in My Factory? Check if the dimensions of the machine you choose are suitable for the area of your production facility.

- How Easy Should the Maintenance and Service of the Machine Be? The machine should be easy to maintain, and quick service support should be available in case of possible malfunctions. Reliable suppliers like Sora Machine usually offer comprehensive technical support and spare parts services.

What are the Advantages of Using Aerosol Filling Machines?

Aerosol filling machines offer many important advantages to businesses that produce aerosol products:

- You can significantly increase your production speed thanks to automatic and semi-automatic systems.

- Precise filling mechanisms guarantee the correct amount of product is filled into each can, which increases product quality.

- Modern aerosol filling machines are equipped with various safety features to ensure a safe working environment.

- They help reduce labor costs and minimize production errors in the long run.

- You can increase your production diversity thanks to models suitable for different product and can types.

How Can I Access Quality and Reliable Solutions in Aerosol Production?

Aerosol filling machines are an indispensable investment for businesses that want to produce aerosol products. Thanks to the wide product range offered by industry leaders like Sora Machine, you can find the most suitable machine for your needs and maximize your production processes. Review Sora Machine aero filling machines to learn more about different machine types, features, and application areas, and guarantee your success in aerosol production. Contact Sora Machine experts for customized solutions for your needs.