The exciting launch of a new product is approaching, or you need to meet the increasing demand for your existing products. In this situation, setting up a new production line becomes an inevitable step. However, this process involves countless complex steps, from equipment procurement to logistics, installation, and personnel training. So, is there a way to gather all this complexity under one roof and make the process as seamless as possible? This is exactly where “turnkey” solutions come into play. In this blog post, we will explore, using a question-based approach, why turnkey solutions should be your first choice when setting up a new production line.

Is it Possible to Manage the Entire Process with a Single Point of Contact? How Do Turnkey Solutions Provide This Convenience?

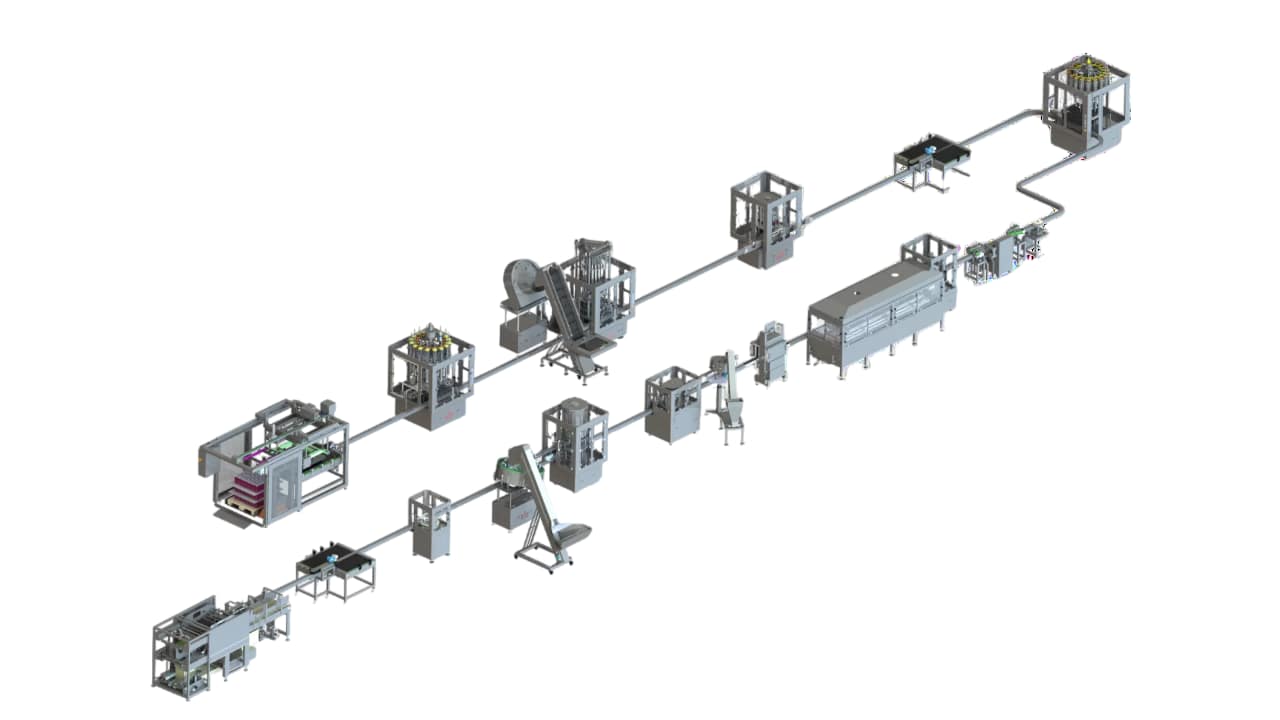

When setting up a new production line, communicating separately with different suppliers, engineering firms, logistics companies, and installation teams, and bringing all these pieces together, requires a great deal of time and effort. The different deadlines, expectations, and communication styles of each stakeholder can make managing the process difficult and lead to errors. Turnkey solutions eliminate this complex structure by offering you a single point of contact. So what does this mean?

A turnkey solution provider is responsible for all stages of your new production line, from project planning to equipment procurement, installation, testing, and even personnel training. You simply communicate your needs and expectations to this single point of contact and leave the rest to their expertise. This way, instead of dealing with multiple different companies, you can follow the entire process from a single source. Communication channels are simplified, coordination problems are minimized, and the overall management of the project is significantly facilitated. Having a single point of contact for potential problems or change requests speeds up the resolution process and increases efficiency.

How Can I Save Time and Budget When Setting Up a New Production Line? What is the Role of Turnkey Solutions in This Regard?

The process of setting up a new production line can often encounter unforeseen delays and cost increases. Factors such as separate agreements with different suppliers, logistical problems, and technical malfunctions that arise during installation can lead to both time loss and budget overruns. Turnkey solutions play a critical role in minimizing these risks. But how?

Turnkey providers, thanks to their experience and expertise gained in similar projects, plan every stage of the project in detail and create realistic timelines. They manage supply chains effectively, procure equipment on time, and optimize installation processes. Additionally, they usually offer a fixed price quote at the beginning of the project. This prevents unexpected cost increases and allows you to better control your budget. They can also provide advantages in equipment and material costs due to their bulk purchasing power. In short, turnkey solutions significantly contribute to the project being completed on time and within budget.

Who Can Offer the Most Suitable Solutions for My Production Line Needs? What Does the Expertise and Experience of Turnkey Providers Mean?

The production needs of every business are different. Instead of standard solutions, it is crucial to determine the most suitable equipment, technologies, and production processes for your business’s specific requirements. So, who can make the most accurate decisions in this regard? This is where the expertise and experience of turnkey solution providers come into play.

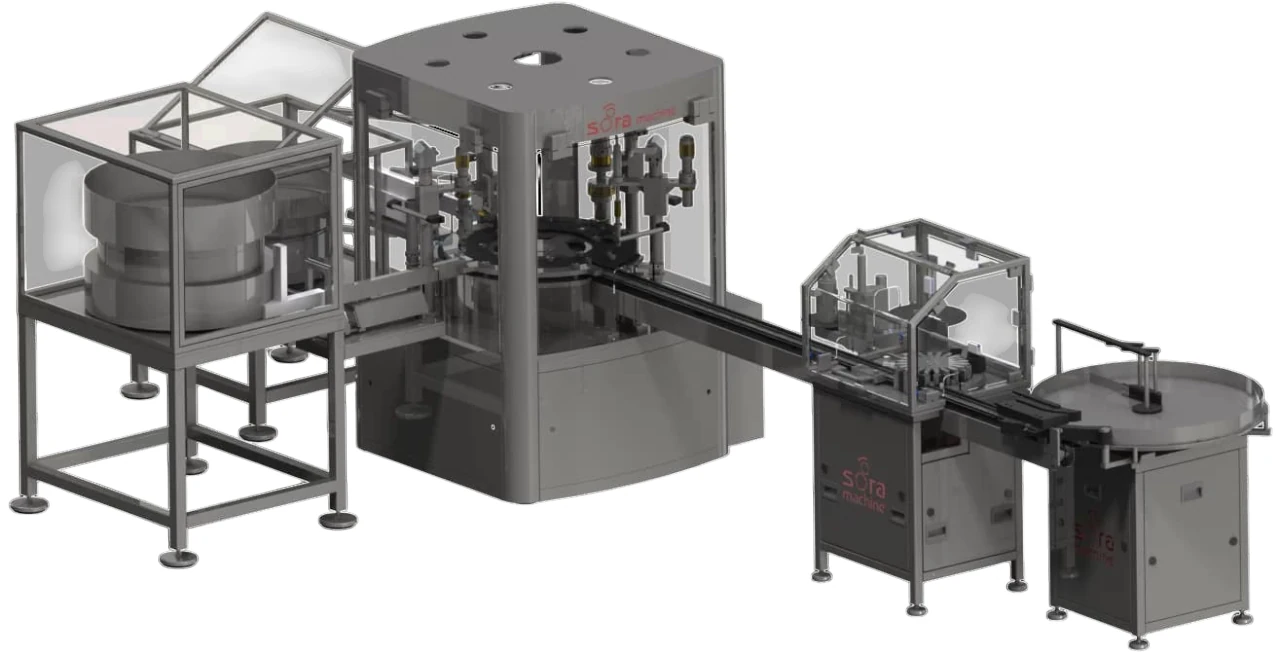

These providers have in-depth knowledge gained from similar projects in different sectors. By analyzing the specific needs of your business, they can design the most suitable equipment, automation level, and production flow for you. They not only offer existing technologies but also provide scalable solutions by considering your future growth potential. Thanks to their teams of expert engineers and technicians, they can produce effective solutions even for the most complex technical problems. This helps you increase the efficiency and competitiveness of your production line.

What Should I Do If I Need a Custom Production Line Instead of Standard Solutions? How Does the Turnkey Approach Offer This Flexibility?

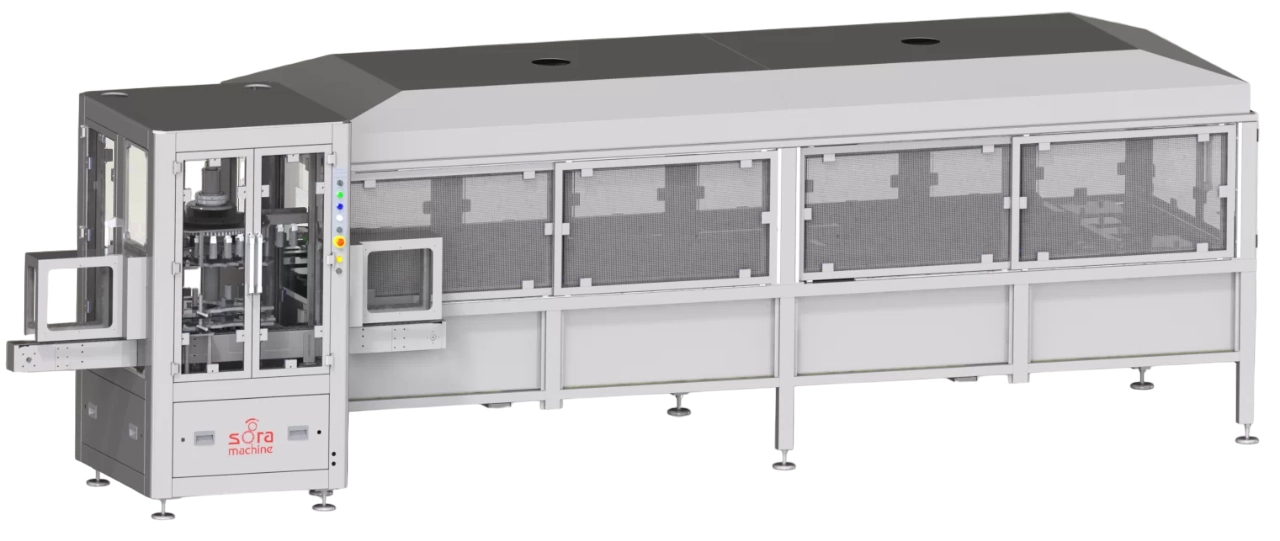

While there are many standard equipment and solutions available on the market, you may want to set up a production line that fully meets the unique needs of your business. Instead of offering a standard product, turnkey providers work closely with you to understand your needs in detail. They design a custom production line by considering many factors such as the characteristics of the product to be produced, production volume, quality standards, and factory space limitations. They can select the most suitable equipment for your needs, integrate custom software, and optimize your production processes. This way, instead of a “one size fits all” approach, you have a production line that perfectly fits the specific requirements of your business.

Who Bears the Risks I May Encounter When Setting Up a New Production Line? How Does Turnkey Solutions Provide an Advantage in Risk Management?

The process of setting up a new production line carries many potential risks, from equipment malfunctions to installation errors, delays, and non-compliance with legal regulations. Managing these risks and resolving potential problems can be a significant burden for businesses. Turnkey solutions provide a great advantage by taking on a significant portion of these risks. How so?

Turnkey contracts usually include specific performance criteria and delivery times. The provider is obliged to meet these criteria and complete the project on time. Ensuring that the equipment is installed correctly and is operational is also their responsibility. They have experienced teams and solution-oriented approaches to deal with potential technical problems or unexpected situations. In addition, they can provide support in matters such as obtaining legal permits and ensuring compliance with environmental regulations in some cases. This significantly reduces the risk burden on your business, allowing you to focus on your core operations.

How Quickly Can My Production Line Be Set Up and Start Operating? What is the Contribution of Turnkey Solutions to the Fast Installation and Commissioning Process?

To enter the market quickly and gain a competitive advantage, it is important for the new production line to be set up and start operating as soon as possible. So, how do turnkey solutions speed up this process?

Turnkey providers optimize installation and commissioning processes thanks to their expertise in project planning and management. The installation time is significantly shortened by ensuring the timely procurement of necessary equipment, effective management of logistics processes, and coordinated work of experienced installation teams. After the installation is complete, the testing and commissioning of the production line are also carried out quickly. Thanks to the simultaneous execution of personnel training, the production line can start operating at full capacity in the shortest possible time. This ensures that your business does not miss opportunities in the market and achieves a faster return on investment.

How Will My Support and Maintenance Needs Be Met After the Production Line is Set Up? What Continuous Support Services Do Turnkey Providers Offer?

After a new production line is set up, regular maintenance and quick support against potential malfunctions are important to ensure that it operates efficiently and for a long time. Turnkey solution providers usually continue to support you even after installation. What might these support services include?

Many turnkey providers offer comprehensive training programs for your personnel to use the new production line effectively. They also offer quick solutions to potential malfunctions with technical support lines and on-site service options. They help you keep the performance of your production line at the highest level with regular maintenance agreements. In some cases, they can also provide support regarding software updates and technological improvements. Thanks to these continuous support services, you can ensure that your production line operates smoothly for many years and protect the value of your investment.

Is it Possible to Accelerate the Return on Investment (ROI)? How Do Turnkey Solutions Contribute to This Process?

Setting up a new production line requires a significant cost, and every business wants this investment to pay off as quickly as possible. So, how can turnkey solutions help you accelerate the return on your investment?

Turnkey solutions allow you to start generating revenue earlier by ensuring the quick completion of the project and the early operation of the production line. Thanks to optimized production processes and the right equipment selection, your production efficiency increases and your costs decrease. Fewer disruptions and a smoother operation minimize production losses. When all these factors come together, turnkey solutions can significantly shorten the payback period of your investment.

How Important is it for My Production Line to Adapt to Future Needs? What Does Turnkey Solutions Offer in Terms of Scalability?

As businesses grow and market demands change, production lines also need to keep up with these changes. So, what advantages do turnkey solutions offer in terms of adapting your production line to future needs?

Many turnkey providers plan the production lines they design by considering potential future expansions and changes. Thanks to modular equipment and flexible production systems, you can easily make adjustments to increase your production capacity or produce different products. This scalability feature allows your business to achieve its long-term growth goals and respond quickly to changing market demands.

How Can I Guarantee That My New Production Line Meets Quality Standards? How Do Turnkey Providers Manage Quality Control Processes?

Production quality is vital for customer satisfaction and brand reputation. So, how do turnkey solution providers guarantee that your new production line meets the specified quality standards?

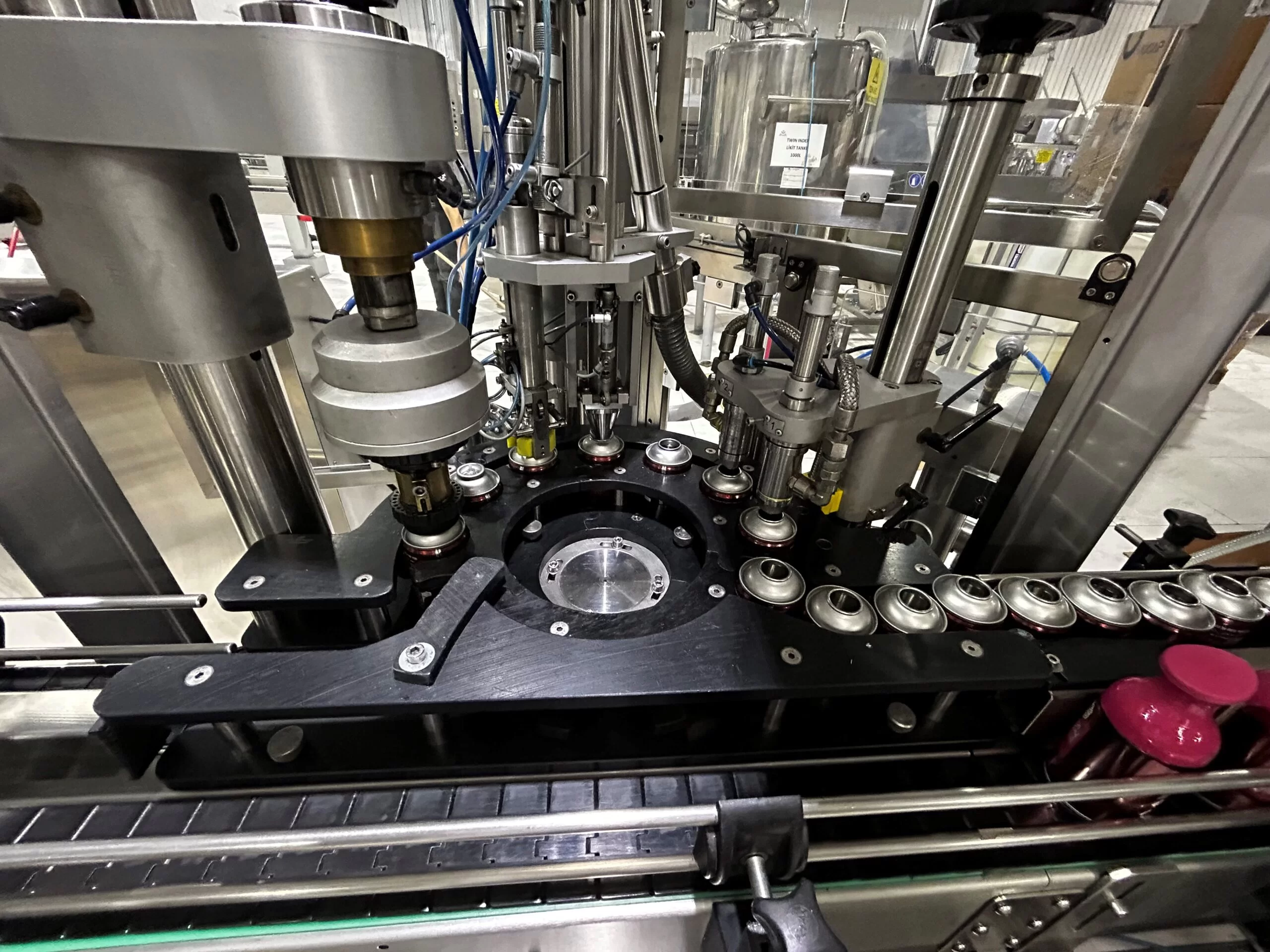

Turnkey providers implement strict quality control procedures at every stage of the project process. Compliance with quality standards is audited at every step, from equipment selection to the installation phase and final tests. Equipment with the necessary certifications is used, and production processes are designed according to international quality standards. This ensures that the products you manufacture are of high quality and meet customer expectations.

Are Technological Integration and Automation Processes Complex for Me? How Do Turnkey Solutions Help in This Regard?

Today’s modern production lines often include complex technological systems and automation solutions. The integration and correct operation of these systems require expertise. So, how can turnkey solutions help you in these complex processes?

Turnkey providers have experienced experts in the integration of automation systems, software, and other technological components. By determining the most suitable level of automation for your business needs, they ensure that these systems are integrated smoothly and work together. This makes your production processes more efficient, reduces human errors, and increases overall operational excellence.

Is Environmental Sustainability a Priority for Me? What Solutions Can Turnkey Providers Offer in This Regard?

Today, the environmental impact of businesses is becoming increasingly important. Sustainable production practices have become critical in terms of both legal requirements and consumer expectations. So, if environmental sustainability is a priority for you, what solutions can turnkey providers offer in this regard?

Many turnkey providers specialize in energy-efficient equipment, waste management systems, and other environmental sustainability solutions. They can integrate technologies and practices that will minimize environmental impact when designing your production line. This allows you to both fulfill your environmental responsibility and reduce your operating costs in the long run.

Setting up a new production line can be a complex and challenging process. However, turnkey solutions, thanks to the numerous advantages they offer, make this process much easier, faster, and more efficient for businesses. Considering the benefits such as ease of management with a single point of contact, time and cost savings, leveraging expertise and experience, solutions tailored to specific needs, risk management, fast installation, continuous support, rapid return on investment, scalability, quality assurance, technological integration, and environmental sustainability, evaluating turnkey solutions for your new production line investment will be a smart decision. Remember, working with the right solution partner is the key to the success of your project.